PVDF-PEO solid composite polymer electrolyte and preparation method thereof

A PVDF-PEO, composite polymer technology, used in hybrid capacitor electrolytes, capacitor electrolytes/absorbents, electrolytic capacitors, etc., can solve problems such as difficult demoulding, avoid environmental pollution, good dimensional stability, high room temperature ions Effects of Conductivity and Lithium Ion Migration Number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The technical solutions of the present invention are not limited to the following specific embodiments.

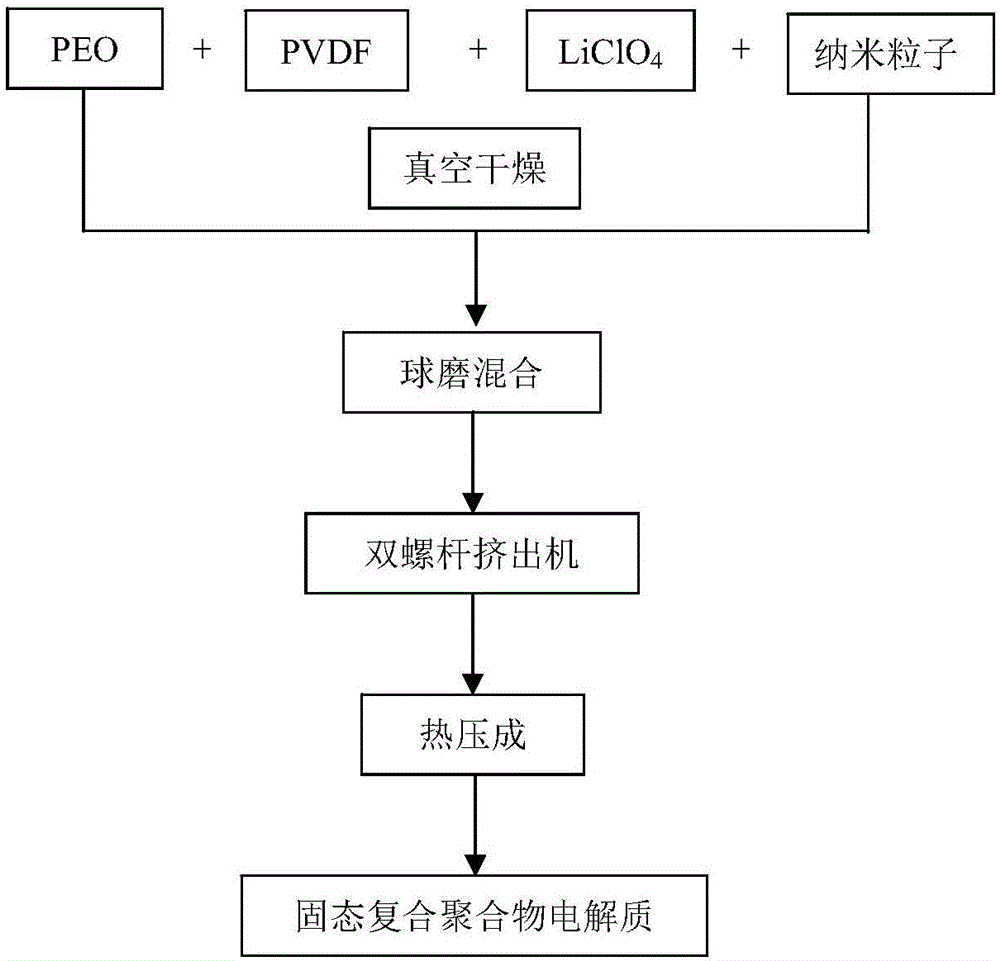

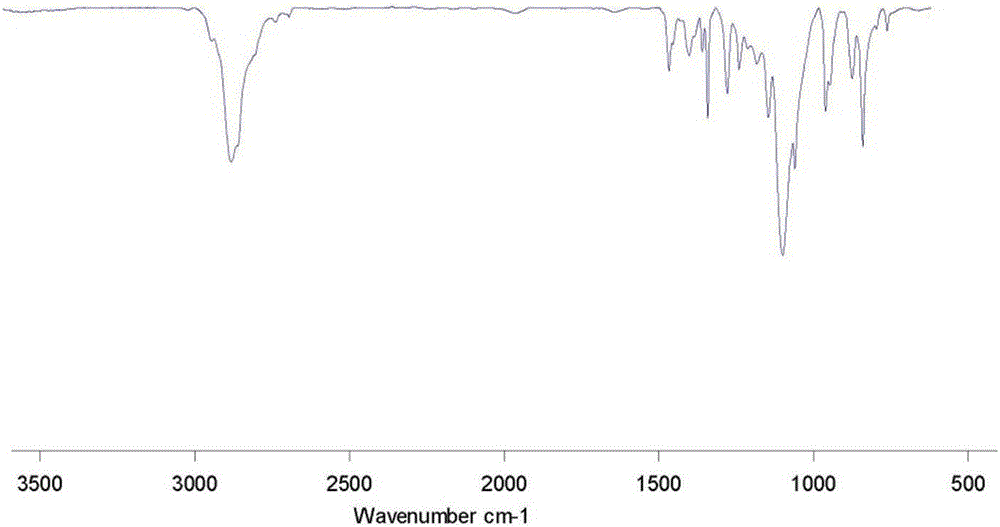

[0018] Weigh 0.6g LiClO 4 and 0.20g Nano Y 2 O 3 and 0.05g nano-Al 2 O 3 , dried under vacuum at 100°C for 24h before use. 4.8 g of PEO with a molecular weight of 300,000 and 1.3 g of PVDF with a molecular weight of 300,000 were weighed in proportion to form a polymer matrix, and the polymer matrix was vacuum-dried at 50° C. for 24 hours. The above polymer matrix, LiClO 4 , Nano Y 2 O 3 and Al 2 O 3 Enter N 2 Protected planetary ball mill, after ball milling for 3 hours, take out the raw material and send it to a micro twin-screw hot press for extrusion, and the extrusion temperature is 175 ℃. Weigh and put an appropriate amount of the extruded material into a polytetrafluoroethylene mold, and hot-press at 115° C. under a pressure of 10 MPa for 10 minutes to obtain a uniform polymer electrolyte. When LiClO 4 The mass fraction is only 5%. The AC impedanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com