Aqueous dispersion, and laminate

A water-based dispersion and acid modification technology, which is applied in the direction of layered products, chemical instruments and methods, synthetic resin layered products, etc., can solve the problems of durability decline, hydrolysis, etc., and achieve excellent content resistance and liquid stability Excellent, good chemical resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

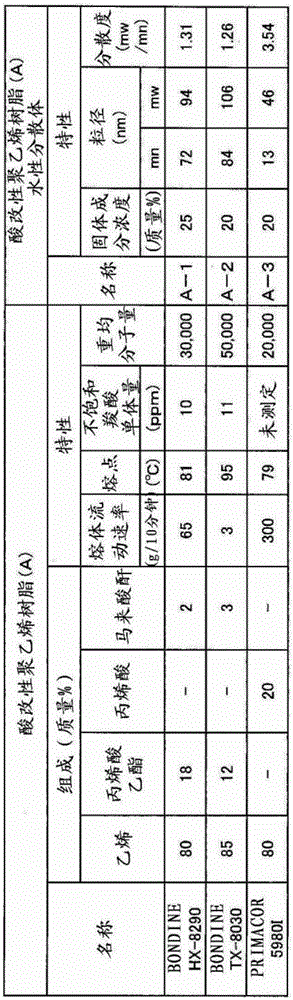

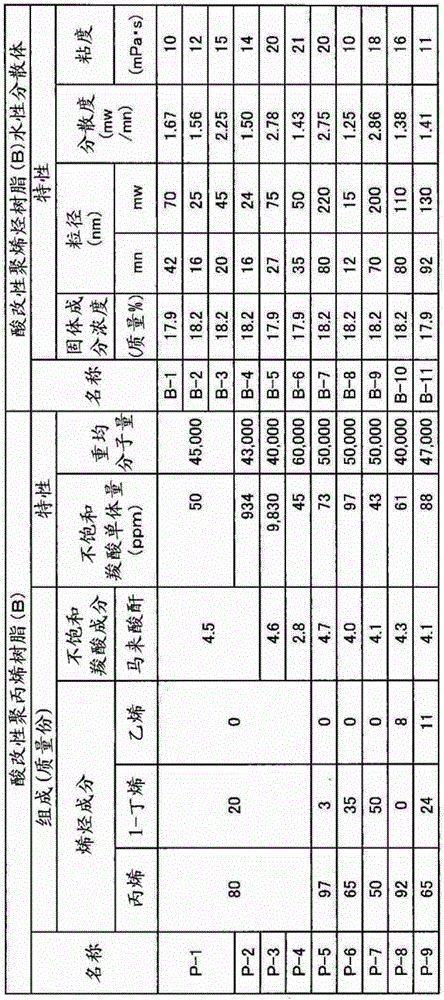

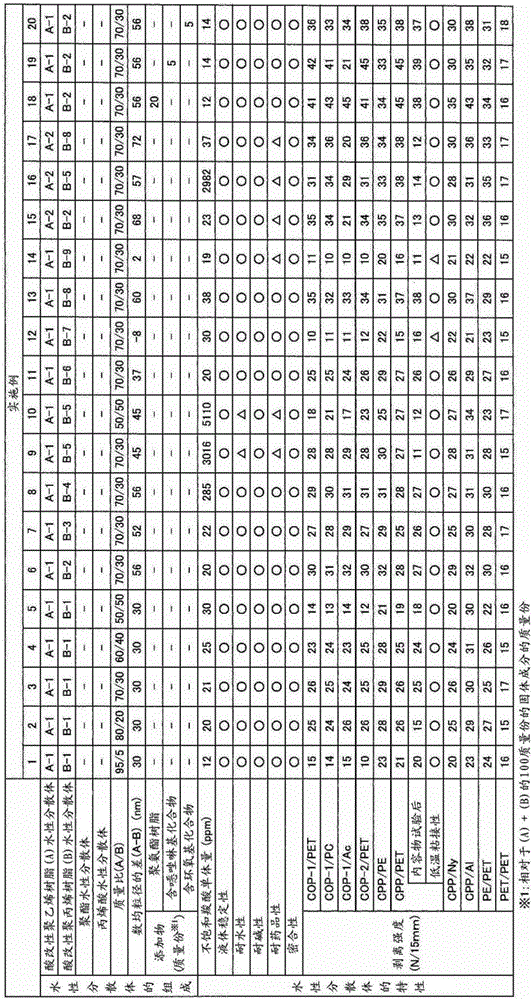

Method used

Image

Examples

manufacture example 1

[0229] Production Example 1: Acid-modified polypropylene resin P-1

[0230] After 280 g of propylene-butene copolymer (mass ratio: propylene / 1-butene=80 / 20) was heated and dissolved in 470 g of xylene in a four-necked flask under a nitrogen environment, the temperature in the system was kept at 140° C. While stirring, 40.0 g of maleic anhydride as an unsaturated carboxylic acid and 28.0 g of dicumyl peroxide as a radical initiator were added over 2 hours, respectively, and then reacted for 6 hours. After completion of the reaction, the obtained reactant was poured into a large amount of acetone to precipitate a resin.

[0231] The precipitated resin was washed once with an acetone solution of triethylamine (mass ratio: triethylamine / acetone=1 / 4), and after that, after washing with acetone to reduce unreacted maleic anhydride, Drying was performed in a reduced-pressure dryer to obtain acid-modified polypropylene resin P-1.

manufacture example 2

[0232] Production Example 2: Acid-modified polypropylene resin P-2

[0233] In manufacture example 1, except having changed the acetone solution of triethylamine into acetone, and having changed the subsequent acetone washing into methanol washing, the same operation was performed, and the acid-modified polypropylene resin P-2 was obtained.

manufacture example 3

[0234] Production Example 3: Acid-modified polypropylene resin P-3

[0235] In Production Example 1, the addition amount of maleic anhydride was set at 60.0 g instead of 40.0 g, and the cleaning step of the acetone solution of triethylamine and the cleaning step of acetone were omitted, except that, the same operation was carried out to obtain acid-modified Polypropylene resin P-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com