Pigments from tea to brown

A brown and pigment technology, applied in the functions of food ingredients, organic dyes, applications, etc., to achieve excellent foaming and foaming stability, excellent acid and/or salt resistance, excellent foaming and foaming stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0121] Regarding the type of alkali used in the preparation of the alkaline aqueous solution, any alkali that can be used in the field of food and beverage products may be used, for example, sodium hydroxide, potassium hydroxide, sodium phosphate, potassium phosphate, sodium carbonate, Potassium carbonate, calcium hydroxide, barium hydroxide, calcium hydroxide, calcium carbonate, ammonium hydroxide, ammonia, aluminum hydroxide, iron hydroxide, etc. These bases may be used individually by 1 type, and may be used in combination of 2 or more types.

[0122] In addition, the alkaline aqueous solution may be an aqueous solution in which the alkali is added so as to satisfy a predetermined pH with respect to water, and may contain additives such as alcohol, preservatives, solubilizers, and defoamers as necessary.

[0123] Regarding the temperature conditions at the time of oxygen supply, usually 30 to 100°C, preferably 50 to 100°C, and more preferably 70 to 100°C are mentioned.

[0124] R...

Embodiment

[0171] Hereinafter, examples and the like are given to specifically explain the present invention, but the present invention is not limited to these examples and will be explained.

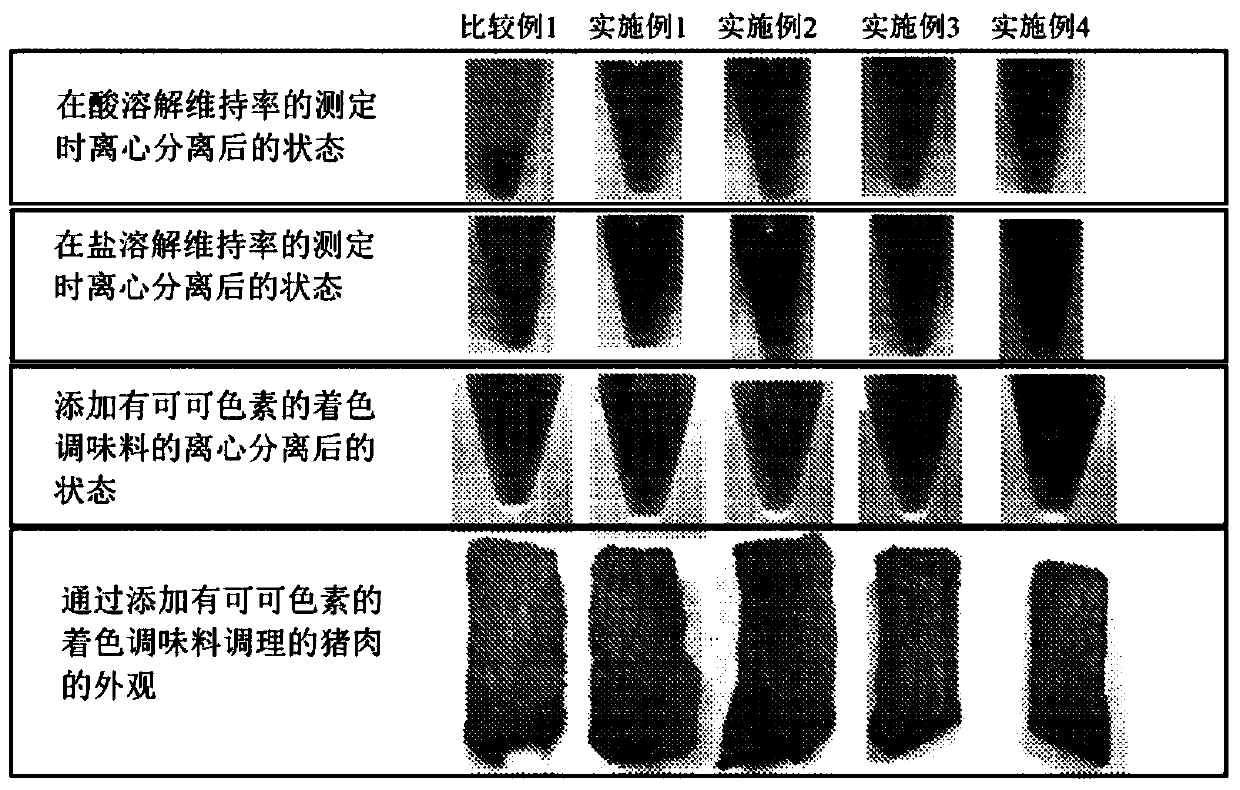

[0172] Reference Test Example 1: Performance evaluation of existing cocoa pigment under low pH conditions and high salt concentration conditions

[0173] 1. Manufacturing of Cocoa Color

[0174] Use existing methods to produce cocoa pigment. Specifically, the cocoa dye is produced by performing the following extraction process and purification process.

[0175]

[0176] 100 g of cocoa soybean meal was added to 2000 ml of a pH 12.52 sodium hydroxide aqueous solution, and the extraction process was performed for 2 hours while stirring at 80°C. After the extraction treatment, the solid content is removed to obtain an extract containing cocoa pigment.

[0177]

[0178] The extract obtained in the above was concentrated, acetone was added, and the pH was adjusted to 3 with hydrochloric acid, and then it was ...

Embodiment 28~30

[0313] 100 g of cocoa soybean meal was added to 2000 ml of a pH 12.52 sodium hydroxide aqueous solution, and the extraction process was performed for 2 hours while stirring at 80°C. After the extraction process, the solid content is removed to obtain an extract containing cocoa pigment. After concentrating the obtained extract, acetone was added, and the pH was adjusted to 3 with hydrochloric acid. After that, it was allowed to stand at 5°C for 16 hours to precipitate impurities such as gums. Next, after removing impurities by filtration, the pH was adjusted to 10 with sodium hydroxide, and the mixture was allowed to stand at 5°C for 16 hours to analyze the cocoa pigment composition. After recovering the precipitated cocoa colorant, it is dissolved in water, and then the acetone is removed by concentration, and purified water is further added to give the color value E 10% (500nm) = 130 converted to about 1% by weight, and a purified cacao dye aqueous solution was obtained.

[03...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com