Preparation methods of chitosan and organic water-soluble fertilizer thereof

A chitosan and polysaccharide technology, applied in the field of new chitosan organic water-soluble fertilizers, can solve the problems of decreased yield increase, human and environmental hazards, pollution, etc., to reduce the dependence on chemical fertilizers and pesticides, promote crop production, The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

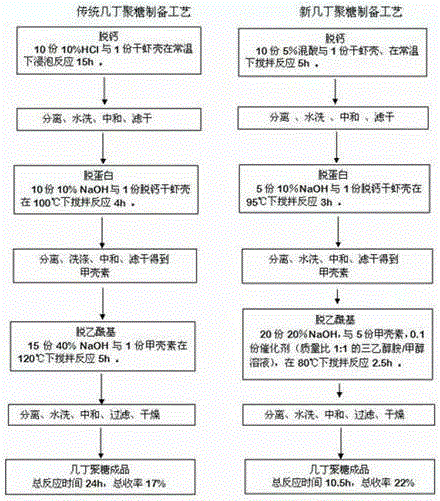

Method used

Image

Examples

Embodiment 1

[0035] First weigh 350g of tap water in a beaker, then add 33g of zinc sulfate, 82g of ferric chloride, 54g of manganese sulfate, and 28g of ammonium molybdate (stirring while adding, when one substance is dissolved, add Another substance), after all the addition, continue to stir for 15 minutes, then add 200g of 3% chitosan 2.5% glacial acetic acid solution to it, continue to stir for 15 minutes, add 26g of isopropanol while stirring , 22g n-butanol, 48g polyaspartic acid, 15g fatty alcohol polyoxyethylene ether, 28g hexamethyl-p-fuchrine chloride (add another substance after one substance is dissolved), and continue stirring for 15 minutes. Then add 50g of sodium hydroxide solution with a mass fraction of 10%, adjust the pH to 6-7, then add 38g of tap water, disperse and mix at a high speed under normal pressure and a temperature of 30-35°C to obtain 1000g of finished product, and fill it with a plastic bottle Just pack and seal.

[0036] When in use, get the above-prepared...

Embodiment 2

[0039] First weigh 350g of tap water in a beaker, then add 33g of zinc sulfate, 82g of ferric chloride, 54g of manganese sulfate, and 28g of ammonium molybdate (stirring while adding, when one substance is dissolved, add Another substance), after all the addition, continue to stir for 15 minutes, then add 200g of 3% chitosan 2.5% glacial acetic acid solution to it, continue to stir for 15 minutes, add 26g of isopropanol while stirring , 22g n-butanol, 48g polyaspartic acid, 15g fatty alcohol polyoxyethylene ether, 28g hexamethyl-p-fuchrine chloride (add another substance after one substance is dissolved), and continue stirring for 15 minutes. Then add 50g of sodium hydroxide solution with a mass fraction of 10%, adjust the pH to 6-7, then add 38g of tap water, disperse and mix at a high speed under normal pressure and a temperature of 30-35°C to obtain 1000g of finished product, and fill it with a plastic bottle Just pack and seal.

[0040] When in use, take the organic water...

Embodiment 3

[0042] First weigh 350g of tap water in a beaker, then add 33g of zinc sulfate, 82g of ferric chloride, 54g of manganese sulfate, and 28g of ammonium molybdate (stirring while adding, when one substance is dissolved, add Another substance), after all the addition, continue to stir for 15 minutes, then add 200g of 3% chitosan 2.5% glacial acetic acid solution to it, continue to stir for 15 minutes, add 26g of isopropanol while stirring , 22g n-butanol, 48g polyaspartic acid, 15g fatty alcohol polyoxyethylene ether, 28g hexamethyl-p-fuchrine chloride (add another substance after one substance is dissolved), and continue stirring for 15 minutes. Then add 50g of sodium hydroxide solution with a mass fraction of 10%, adjust the pH to 6-7, then add 38g of tap water, disperse and mix at a high speed under normal pressure and a temperature of 30-35°C to obtain 1000g of finished product, and fill it with a plastic bottle Just pack and seal.

[0043] When in use, take the organic water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com