Preparation method of macromolecular modified self-supporting carbon nanotube assembling membrane

A technology of carbon nanotubes and polymers, which is applied in the field of membrane separation, can solve the problems of reduced service life, reduced film thickness, and reduced membrane strength, and achieves the effects of increased permeation flux, reduced thickness, and reduced use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

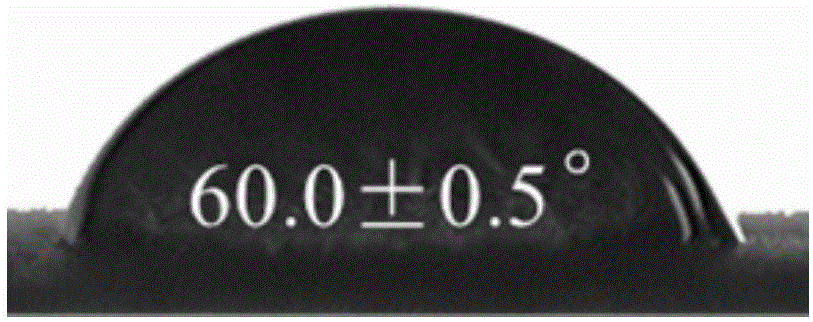

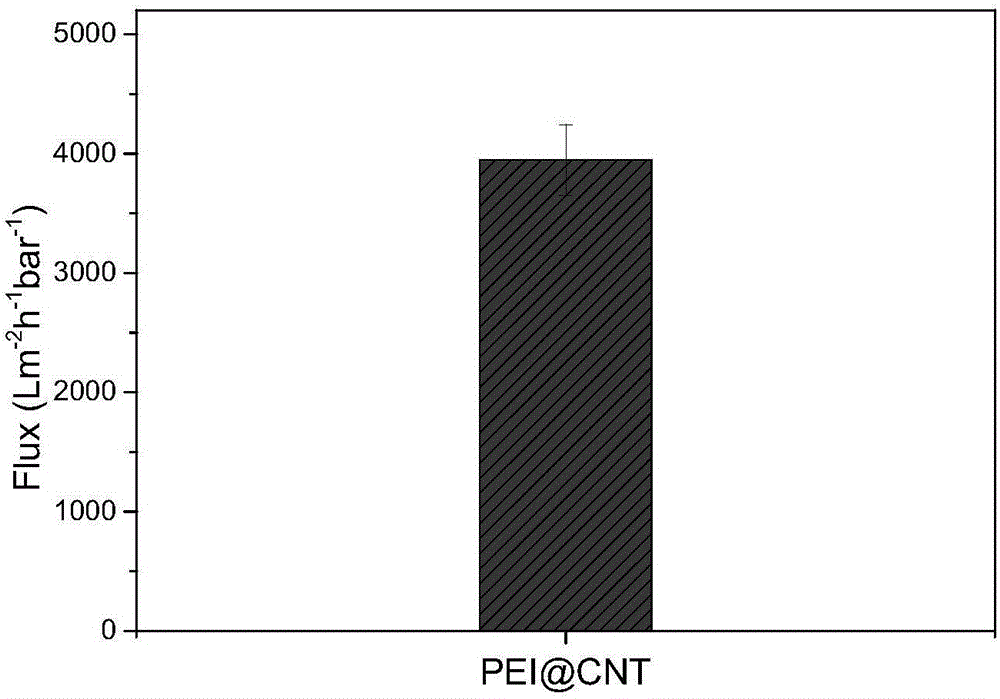

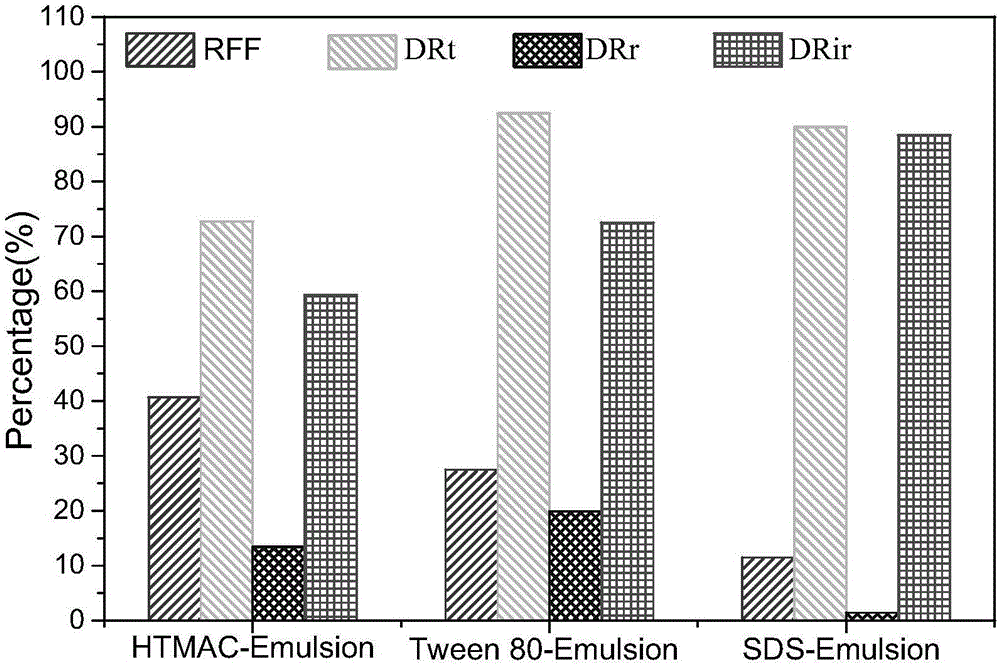

[0027] Embodiment 1, preparation of polyethyleneimine modified self-supporting carbon nanotube assembly film, the preparation process is as follows:

[0028] Step 1. Preparation of polyethyleneimine-modified carbon nanotube solution: Dissolve 0.6g polyethyleneimine in 40mL water. After fully dissolving, polyethyleneimine solution is obtained, and 0.04g polyethyleneimine is added to the polyethyleneimine solution. The carboxylated carbon nanotubes were subjected to ultrasonic reaction for 0.5h, and the obtained polyethyleneimine-modified carbon nanotube solution was left to stand for 12h, centrifuged, and the upper layer solution was taken to obtain a polyethyleneimine-modified carbon nanotube solution.

[0029] Step 2. Preparation of self-supporting carbon nanotube assembly film: Dilute the polyethyleneimine-modified carbon nanotube solution obtained in step 1 with deionized water until the carbon nanotube concentration is 1 mg / L, and take 120 mL of the diluted solution. Vacuu...

Embodiment 2

[0031] Example 2, preparation of polyvinyl alcohol modified self-supporting carbon nanotube assembly film, the preparation process is basically the same as in Example 1, the difference is that the polymer material is changed from polyethyleneimine to polyvinyl alcohol, and finally obtained The polyvinyl alcohol-modified self-supporting carbon nanotube assembly film with a film thickness of about 2 μm is denoted as: PVA@CNT.

[0032] The PVA@CNT ultrafiltration membrane prepared in Example 2 was analyzed by an electron microscope, and the membrane pores were evenly distributed, the film-forming performance was good, and it had a high membrane porosity. Due to the introduction of hydrophilic polyvinyl alcohol, the hydrophilicity of the prepared polyacrylic acid modified self-supporting carbon nanotube assembly film was significantly improved, as shown in Figure 4 . The permeation flux of the prepared polyvinyl alcohol-modified carbon nanotube ultrafiltration membrane is as fol...

Embodiment 3

[0033] Example 3, preparation of polyacrylic acid modified self-supporting carbon nanotube assembly film, the preparation process is basically the same as in Example 1, the difference is that the polymer material therein is replaced by polyacrylic acid from polyethyleneimine, and finally the film thickness is about Polyacrylic acid modified self-supporting carbon nanotube assembly film with a thickness of 2 μm is denoted as: PAA@CNT.

[0034] The PAA@CNT ultrafiltration membrane prepared in Example 3 was analyzed by an electron microscope, and the membrane pores were evenly distributed, the film-forming performance was good, and it had a high membrane porosity. Due to the introduction of hydrophilic polyacrylic acid, the hydrophilicity of the prepared polyacrylic acid modified self-supporting carbon nanotube assembly film was significantly improved, as shown in Figure 7 . The permeation flux of the prepared polyacrylic acid modified carbon nanotube ultrafiltration membrane i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com