A composite enhanced micro-electrolysis simulation treatment method

A technology of simulating treatment and treatment method, applied in the field of micro-electrolysis treatment, can solve the problems of large pH influence and slow rate of oxidative decomposition of hydrogen peroxide, and achieve the effects of high work efficiency, increased possibility, and accelerated reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The invention discloses a composite enhanced micro-electrolysis simulation treatment method, which is specifically as follows:

[0022] (1) Select a pharmaceutical factory to comprehensively discharge wastewater. The water quality: does not contain benzene, COD: 17000-20000mg / L, B / C is 0.05-0.15, and has a pungent smell, where B / C is biological oxygen demand and chemical The ratio of oxygen demand;

[0023] (2) Add acid to the comprehensive discharge wastewater to adjust its pH to 2-5, then add 1%-3% hydrogen peroxide and 50-100mg / L copper ions in sequence, and stir them evenly with a stirring bar;

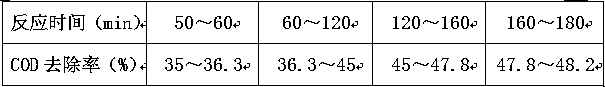

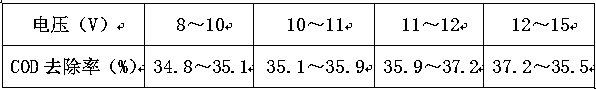

[0024] (3) Insert the anode titanium plate and the cathode titanium plate in the comprehensive discharge wastewater, and set a DC stabilized power supply between the anode titanium plate and the cathode titanium plate. The voltage of the DC stabilized power supply is 10V ~ 12V, and the current is 0.01A~0.1A; then continue to add sintered iron-carbon spheres to the comprehe...

Embodiment 2

[0034] The invention discloses a composite enhanced micro-electrolysis simulation treatment method, which is specifically as follows:

[0035] (1) Select pharmaceutical wastewater containing benzene rings, and add benzene series to it to obtain simulated wastewater. The benzene series include benzene, toluene, ethylbenzene, xylene and styrene, and the addition amount is 45-55mg / L ;

[0036] (2) Add acid to the simulated wastewater to adjust its pH to 2-5, then add 1%-3% hydrogen peroxide and 50-100mg / L copper ions in sequence, and stir them evenly with a stirring rod;

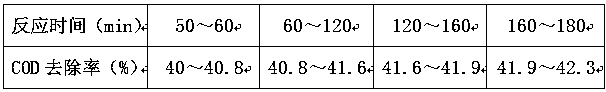

[0037] (3) Insert the anode titanium plate and the cathode titanium plate in the simulated wastewater, and set a DC stabilized power supply between the anode titanium plate and the cathode titanium plate. The voltage of the DC stabilized power supply is 10V ~ 12V, and the current is 0.01 A~0.1A; then continue to add sintered iron-carbon spheres to the simulated wastewater, so that the ratio of the volume of th...

Embodiment 3

[0045] The invention discloses a composite enhanced micro-electrolysis simulation treatment method, which is specifically as follows:

[0046] (1) Select pharmaceutical wastewater that actually contains benzene series, mainly toluene as the main characteristic pollutant, with a concentration range of 50-150mg / L, and also contains a small amount of benzene and ethylbenzene;

[0047] (2) Add acid to the pharmaceutical wastewater to adjust its pH to 2-5, then add 1%-3% hydrogen peroxide and 50-100mg / L copper ions in sequence, and stir them evenly with a stirring rod;

[0048] (3) Insert the anode titanium plate and the cathode titanium plate in the simulated wastewater, and set a DC stabilized power supply between the anode titanium plate and the cathode titanium plate. The voltage of the DC stabilized power supply is 10V ~ 12V, and the current is 0.01 A~0.1A; then continue to add sintered iron-carbon spheres to the pharmaceutical wastewater, so that the ratio of the volume of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com