A kind of less clinker cement and preparation method thereof

A technology for clinker cement and cement clinker, applied in the field of building cement materials, can solve problems such as energy shortage and environmental damage, and achieve the effects of reducing the amount of non-renewable resources, saving resources and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

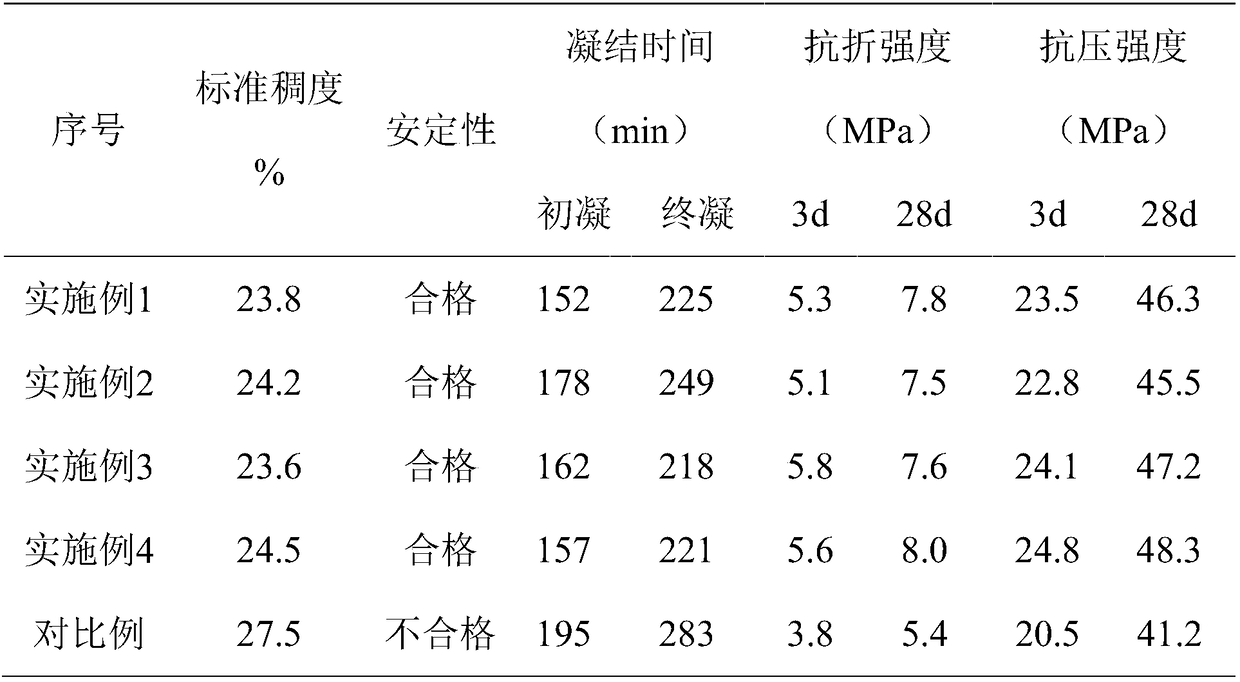

Examples

Embodiment 1

[0023] The invention provides a kind of less clinker cement, each component of this cement is: specific surface area is 400m 2 / kg of ferronickel slag powder 6.0kg, fly ash 0.5kg, slag 0.3kg, desulfurization gypsum 0.3kg, cement clinker 0.5kg, sodium tripolyphosphate 0.1kg, sodium coco alcohol sulfate 0.1kg, slaked lime 0.1kg.

[0024] The present invention also provides the preparation method of this little clinker cement, and this method comprises the following steps:

[0025] (1) Weigh the fly ash, slag, cement clinker, desulfurized gypsum, sodium tripolyphosphate, sodium cocoyl sulfate and hydrated lime of the above-mentioned quality, then pour them into the mill, and grind until the specific surface area is 350m 2 / kg of fine powder;

[0026] (2) Pour the above-mentioned fine powder and the nickel-iron slag micro-powder of the above-mentioned quality into a sample mixer, and mix evenly to obtain the clinker-less cement.

Embodiment 2

[0028] The invention provides a kind of less clinker cement, each component of this cement is: specific surface area is 450m 2 / kg of ferronickel slag powder 7.0kg, fly ash 0.4kg, slag 0.9kg, desulfurization gypsum 0.3kg, cement clinker 1.5kg, sodium tripolyphosphate 0.4kg, sodium coco alcohol sulfate 0.1kg, slaked lime 0.3kg.

[0029] The present invention also provides the preparation method of this little clinker cement, and this method comprises the following steps:

[0030] (1) Weigh the fly ash, slag, cement clinker, desulfurized gypsum, sodium tripolyphosphate, sodium cocoyl sulfate and slaked lime of the above quality, then pour them into the mill, and grind until the specific surface area is 400m 2 / kg of fine powder;

[0031] (2) Pour the above-mentioned fine powder and the nickel-iron slag micro-powder of the above-mentioned quality into a sample mixer, and mix evenly to obtain the clinker-less cement.

Embodiment 3

[0033] The invention provides a kind of less clinker cement, each component of this cement is: specific surface area is 500m 2 / kg of ferronickel slag fine powder 6.0kg, fly ash 1.2kg, slag 0.6kg, desulfurization gypsum 0.3kg, cement clinker 1.2kg, sodium tripolyphosphate 0.3kg, sodium coco alcohol sulfate 0.2kg, slaked lime 0.8kg.

[0034] The present invention also provides the preparation method of this little clinker cement, and this method comprises the following steps:

[0035] (1) Weigh the fly ash, slag, cement clinker, desulfurized gypsum, sodium tripolyphosphate, sodium cocoyl sulfate and slaked lime of the above quality, then pour them into the mill, and grind until the specific surface area is 400m 2 / kg of fine powder;

[0036] (2) Pour the above-mentioned fine powder and the nickel-iron slag micro-powder of the above-mentioned quality into a sample mixer, and mix evenly to obtain the clinker-less cement.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com