Preparation method of phenacetin micropowder

A technology of Xiding micropowder and phenacetin, which is applied in the field of medicine and chemical industry, can solve the problems of narrow particle size distribution, high energy consumption, and low efficiency, and achieve the effects of easy process control, simple production process, and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

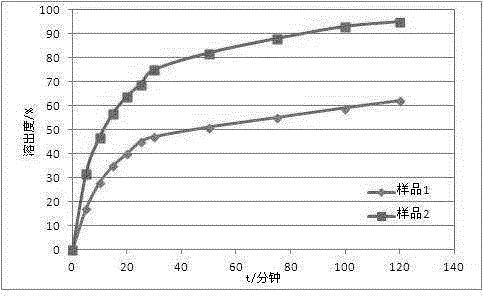

Image

Examples

Embodiment 1

[0021] Add 100 g of ethanol to 100 g of phenacetin bulk drug, heat to 78° C., heat and stir to dissolve. Control the stirring rate to 250 rpm, and add the phenacetin ethanol solution to 500 g of purified water at 40° C. while hot. After the dropwise addition, continue to stir for 30 minutes, then lower the temperature to 15°C, stir and crystallize for 2 hours, filter, and dry to obtain 98.8 g of phenacetin micropowder, with a yield of 98.8%, residual ethanol ≤ 0.1%, and a particle size below 120 mesh accounted for 96%.

Embodiment 2

[0023] Add 180 g of ethanol to 100 g of phenacetin bulk drug, heat to 57° C., heat and stir to dissolve. Control the stirring rate at 330 rpm, and add the phenacetin ethanol solution to 900 g of purified water at 35° C. while hot. After the dropwise addition, continue to stir for 30 minutes, then lower the temperature to 20°C, stir and crystallize for 3 hours, filter, and dry to obtain 98.5 g of phenacetin micropowder, with a yield of 98.5%, residual ethanol ≤ 0.1%, and a particle size below 120 mesh accounted for 96%.

Embodiment 3

[0025] Add 200 g of ethanol to 100 g of phenacetin bulk drug, heat to 50° C., heat and stir to dissolve. Control the stirring rate at 350 rpm, and add the phenacetin ethanol solution to 1000 g of purified water at 30°C while it is hot. After the dropwise addition, continue to stir for 30 minutes, then lower the temperature to 24°C, stir and crystallize for 4 hours, filter, and dry to obtain 96.8 g of phenacetin micropowder, with a yield of 96.8%, residual ethanol ≤ 0.1%, and a particle size below 120 mesh Occupy 97%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com