Material applied to the field of OLED

A field, coupling reaction technology, applied in the field of OLED

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

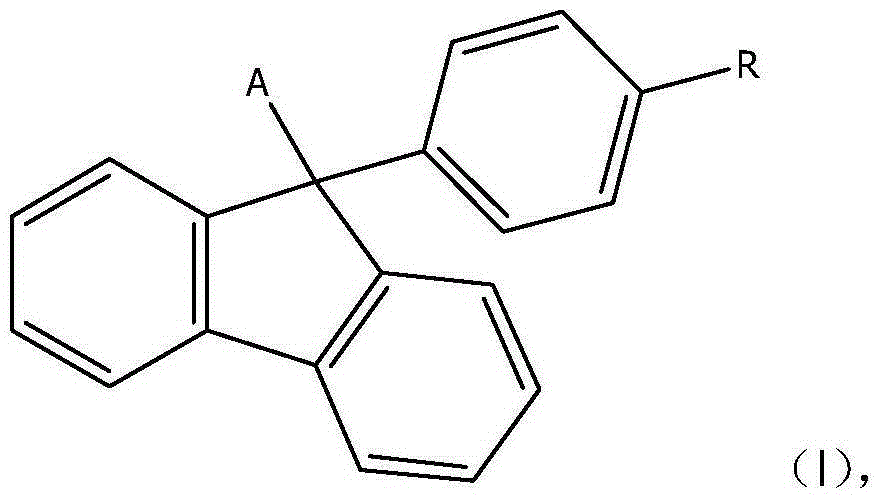

[0040] 1. A compound used in the field of OLEDs, the structure of which is shown in formula (I-1):

[0041]

[0042] 2, the preparation method of described compound comprises:

[0043] Add the toluene of 0.1mol intermediate A-1, 0.1mol intermediate B-1 and 1000mL in the reaction bottle, add potassium carbonate 200mmol and 1mmol catalyst Pd[P(C 6 h 5 ) 3 ] 4 , reflux reaction under nitrogen protection for 24 hours, after the completion of the reaction, add 500ml of distilled water, cool and filter, extract with dichloromethane, wash with salt water, separate the organic layer, remove the organic solvent by rotary evaporation, pass the crude product through the column, and then use dichloromethane and Compound (I-1) was obtained by ethanol recrystallization and purification;

[0044] in,

[0045] 3. Molecular weight characterization MS 639.2311

[0046] H-NMR: 7.53(2H), 7.62(4H), 7.71(4H), 7.58(1H), 7.67(1H), 7.76(1H), 7.34(2H), 7.49(2H), 7.64(2H), 7.61 (2H), 7.64(2H...

Embodiment 2

[0048] 1. A compound used in the field of OLEDs, the structure of which is shown in formula (I-2):

[0049]

[0050] 2, the preparation method of described compound comprises:

[0051] In reaction bottle, add the toluene of 0.1mol intermediate A-2, 0.1mol intermediate B-2 and 1000mL, add potassium carbonate 200mmol and 1mmol catalyst Pd[P(C 6 h 5 ) 3 ] 4 , reflux reaction under nitrogen protection for 24 hours, after the completion of the reaction, add 500ml of distilled water, cool and filter, extract with dichloromethane, wash with salt water, separate the organic layer, remove the organic solvent by rotary evaporation, pass the crude product through the column, and then use dichloromethane and Compound (I-2) was obtained by ethanol recrystallization and purification;

[0052] in,

[0053] 3. Molecular weight characterization MS 655.2082

[0054] H-NMR: 7.53(2H), 7.62(4H), 7.71(4H), 7.58(1H), 7.75(1H), 7.78(1H), 7.39(2H), 7.49(2H), 7.64(2H), 7.61 (2H), 7.64(2H), ...

Embodiment 3

[0056] 1. A compound used in the field of OLEDs, the structure of which is shown in formula (I-3):

[0057]

[0058] 2, the preparation method of described compound comprises:

[0059] In reaction bottle, add the toluene of 0.1mol intermediate A-3, 0.1mol intermediate B-3 and 1000mL, add potassium carbonate 200mmol and 1mmol catalyst Pd[P(C 6 h 5 ) 3 ] 4 , reflux reaction under nitrogen protection for 24 hours, after the completion of the reaction, add 500ml of distilled water, cool and filter, extract with dichloromethane, wash with salt water, separate the organic layer, remove the organic solvent by rotary evaporation, pass the crude product through the column, and then use dichloromethane and Compound (I-3) was obtained by ethanol recrystallization and purification;

[0060] in,

[0061] 3. Molecular weight characterization MS 655.2082

[0062] H-NMR: 7.53(2H), 7.62(4H), 7.71(4H), 7.58(1H), 7.67(1H), 7.76(1H), 7.34(2H), 7.49(2H), 7.62(2H), 7.67 (2H), 7.56(2H), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com