Deepening agent for dyed polyester fabric and preparation method thereof

A technology of polyester fabric and deepening agent, applied in the direction of dyeing, textile and paper making, etc., can solve the problems of hard hand, increased stiffness, decreased dry/wet rubbing fastness, etc. Good color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

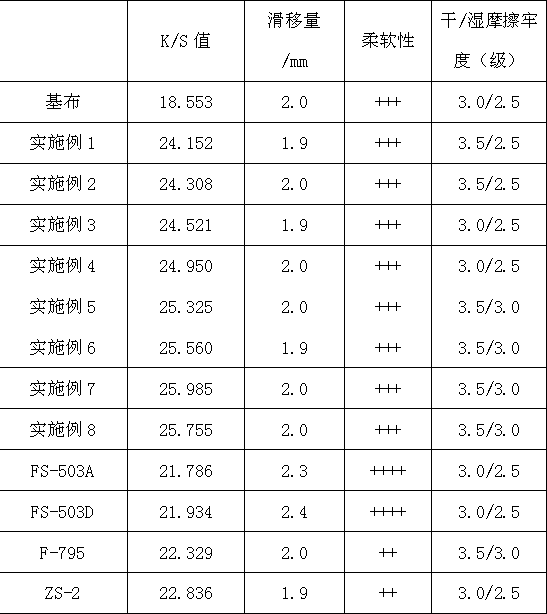

Image

Examples

Embodiment 1

[0033] (1) Add 0.002 parts of cetyltrimethylammonium chloride, 0.002 parts of AEO-7, and 10 parts of deionized water into the first reactor, and stir until completely dissolved;

[0034] Then add 16 parts of methyl methacrylate, 2 parts of styrene, 2 parts of acrylonitrile, 1 part of ethylene glycol methacrylate, and 4 parts of trifluoromethyl methacrylate into the first reactor, and stir for 20 minutes. Prepare a pre-emulsion;

[0035] (2) Take out about 2 / 6 of the pre-emulsion of step (1) and put it into the second reactor for use;

[0036] (3) Take out about 3 / 6 of the pre-emulsion in step (1) and put it into the dropper for use;

[0037] (4) Add 0.001 part of cetyltrimethylammonium chloride, 0.001 part of AEO-7, and 50 parts of deionized water into the first reactor (where the seed pre-emulsion remains), and add azobisisobutyl An initiator aqueous solution prepared by 0.001 part of amidine hydrochloride and 2 parts of deionized water was stirred and heated to 70°C until ...

Embodiment 2

[0043] (1) Add 0.002 parts of cetyltrimethylammonium chloride, 0.002 parts of AEO-9, and 10 parts of deionized water into the first reactor, and stir until completely dissolved;

[0044] Then add 16 parts of methyl methacrylate, 2 parts of styrene, 2 parts of acrylonitrile, 1 part of ethylene glycol methacrylate, 2 parts of trifluoromethyl methacrylate, and 2 parts of hexafluorobutyl methacrylate In the first reactor, stir for 20 minutes to prepare a pre-emulsion;

[0045] (2) Take out about 2 / 6 of the pre-emulsion of step (1) and put it into the second reactor for use;

[0046] (3) Take out about 3 / 6 of the pre-emulsion in step (1) and put it into the dropper for use;

[0047] (4) Add 0.001 part of cetyltrimethylammonium chloride, 0.001 part of AEO-9, and 48 parts of deionized water into the first reactor (where the seed pre-emulsion remains), and add azobisisobutyl An initiator aqueous solution prepared by 0.001 part of amidine hydrochloride and 2 parts of deionized water ...

Embodiment 3

[0053] (1) Add 0.002 parts of octadecyltrimethylammonium chloride, 0.002 parts of AEO-7, and 12 parts of deionized water into the first reactor, and stir until completely dissolved;

[0054] Then add 17 parts of methyl methacrylate, 1 part of styrene, 1 part of acrylonitrile, 2 parts of ethylene glycol methacrylate, and 4 parts of hexafluorobutyl methacrylate into the first reactor, and stir for 30 minutes. Prepare a pre-emulsion;

[0055] (2) Take out about 2 / 6 of the pre-emulsion of step (1) and put it into the second reactor for use;

[0056] (3) Take out about 3 / 6 of the pre-emulsion in step (1) and put it into the dropper for use;

[0057] (4) Add 0.001 part of octadecyltrimethylammonium chloride, 0.001 part of AEO-7, and 46 parts of deionized water into the first reactor (where the seed pre-emulsion remains), and add azobisisobutyl An initiator aqueous solution prepared by 0.001 part of amidine hydrochloride and 2 parts of deionized water was stirred and heated to 70°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com