A kind of quick-drying ultraviolet light curing paint

A UV light, fast-drying technology, applied in the field of coatings, can solve the problems of affecting the polymerization reaction, slow curing speed, consumption of free radicals, etc., and achieve the effects of high condensation content, reduced energy efficiency, and low radiation energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

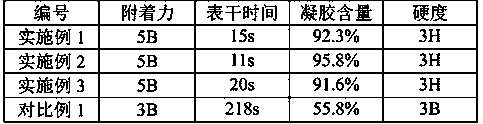

Embodiment 1

[0033] A kind of ultraviolet curable paint, is made up of the component of following percentage by weight:

[0034] Fatty acid modified bisphenol A epoxy acrylate 22%; difunctional aliphatic polyurethane acrylate resin 23%; tetrahydrofurfuryl methacrylate 13%; N-vinylpyrrolidone 14%; allyl glycidyl ether 14% ; Photoinitiator 0.7%; BYK35 40.5%; BYK141 0.5%; Tego 710 0.5%; supplemented to 100% with isobutanol.

Embodiment 2

[0036] A kind of ultraviolet curable paint, is made up of the component of following percentage by weight:

[0037] Fatty acid modified bisphenol A epoxy acrylate 20%; difunctional aliphatic polyurethane acrylate resin 24%; tetrahydrofurfuryl methacrylate 11%; N-vinylpyrrolidone 15%; allyl glycidyl ether 15% ; Photoinitiator 1%; BYK35 40.5%; BYK141 0.5%; Tego 710 0.5%; supplemented to 100% with n-butanol.

Embodiment 3

[0039] A kind of ultraviolet curable paint, is made up of the component of following percentage by weight:

[0040] Fatty acid modified bisphenol A epoxy acrylate 24%; difunctional aliphatic polyurethane acrylate resin 18%; tetrahydrofurfuryl methacrylate 15%; N-vinylpyrrolidone 13%; allyl glycidyl ether 12% ; Photoinitiator 0.5%; BYK35 40.5%; BYK141 0.5%; Tego 710 0.5%; supplemented to 100% with butyl acetate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com