Polyurethane adhesive for bonded foam insoles and preparation method of polyurethane adhesive

A technology of polyurethane adhesives and insoles, which is applied in the direction of polyurea/polyurethane adhesives, adhesive types, insoles, etc., can solve problems such as uneven reaction, violent reaction, and distribution of adhesive agglomerates, and achieve the goal of preparing The method is simple and easy to implement, the reaction efficiency is improved, and the reaction is uniform and stable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

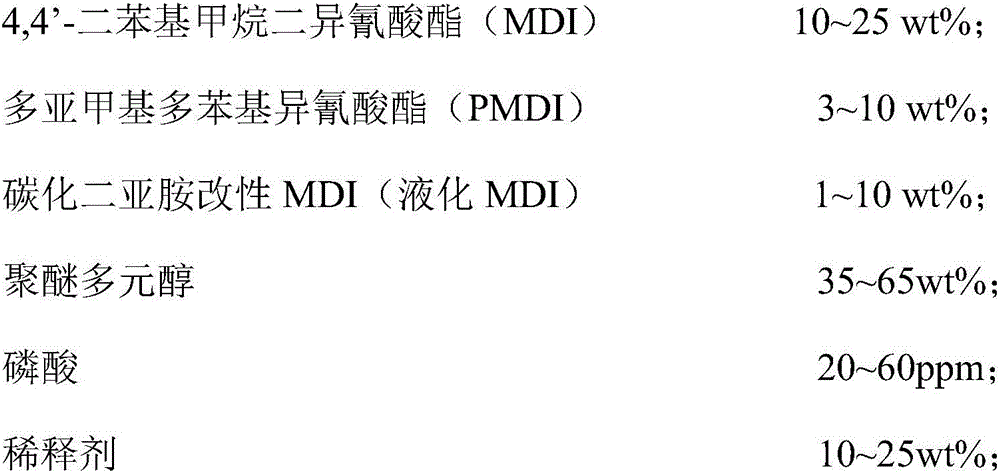

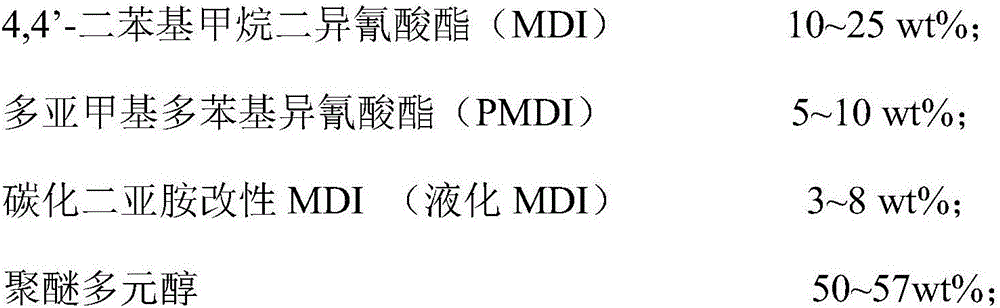

Method used

Image

Examples

Embodiment 1

[0029] 10.00kg polyether polyol P1 (hydroxyl value 32mgKOH / g, ethylene oxide content is 70%) and 20.00kg polyether polyol P2 (hydroxyl value 48mgKOH / g, ethylene oxide content is 65%) Put it into the reaction kettle, heat up to 110°C, vacuum dehydrate for 1.5h, cool down to 45°C, add 1.2g phosphoric acid, 14.00kgMDI and 2.00kg liquefied MDI, heat up to 65°C, react for 2.5h, add 3.00kgPMDI, stir for 0.5h , lower the temperature to below 38°C, add 8.50kg of dichloromethane, and stir for 0.5h to obtain a polyurethane adhesive for regenerated sponge insoles.

Embodiment 2

[0031] 10.00kg polyether polyol P1 (hydroxyl value 36mgKOH / g, ethylene oxide content is 65%) and 20.00kg polyether polyol P2 (hydroxyl value 48mgKOH / g, ethylene oxide content is 65%) Put it into the reaction kettle, heat up to 120°C, vacuum dehydrate for 1.0h, cool down to 55°C, add 1.2g phosphoric acid, 10.00kgMDI and 2.00kg liquefied MDI, heat up to 70°C, react for 2.0h, add 6.00kgPMDI, stir for 1.0h , lower the temperature to below 38°C, add 12.00kg of dichloromethane, and stir for 1.0h to obtain a polyurethane adhesive for regenerated sponge insoles.

Embodiment 3

[0033] 7.05kg polyether polyol P1 (hydroxyl value 36mgKOH / g, ethylene oxide content is 65%) and 21.15kg polyether polyol P2 (hydroxyl value 50mgKOH / g, ethylene oxide content is 70%) Put it into the reaction kettle, heat up to 110°C, vacuum dehydrate for 1.5h, cool down to 45°C, add 2.4g phosphoric acid, 6.00kgMDI and 4.80kg liquefied MDI, heat up to 65°C, react for 2.5h, add 6.00kgPMDI, stir for 1.0h , lower the temperature to below 38°C, add 15.00kg of dichloromethane, and stir for 0.5h to obtain a polyurethane adhesive for regenerated sponge insoles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com