Luminescent glass ceramic, preparation method thereof and application thereof in LED lighting devices

A technology of LED lighting and luminous glass, applied in glass molding, glass manufacturing equipment, luminescent materials, etc., can solve the problems of increasing the difficulty and cost of preparation, reduce the probability of erosion, save costs, and have broad application prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

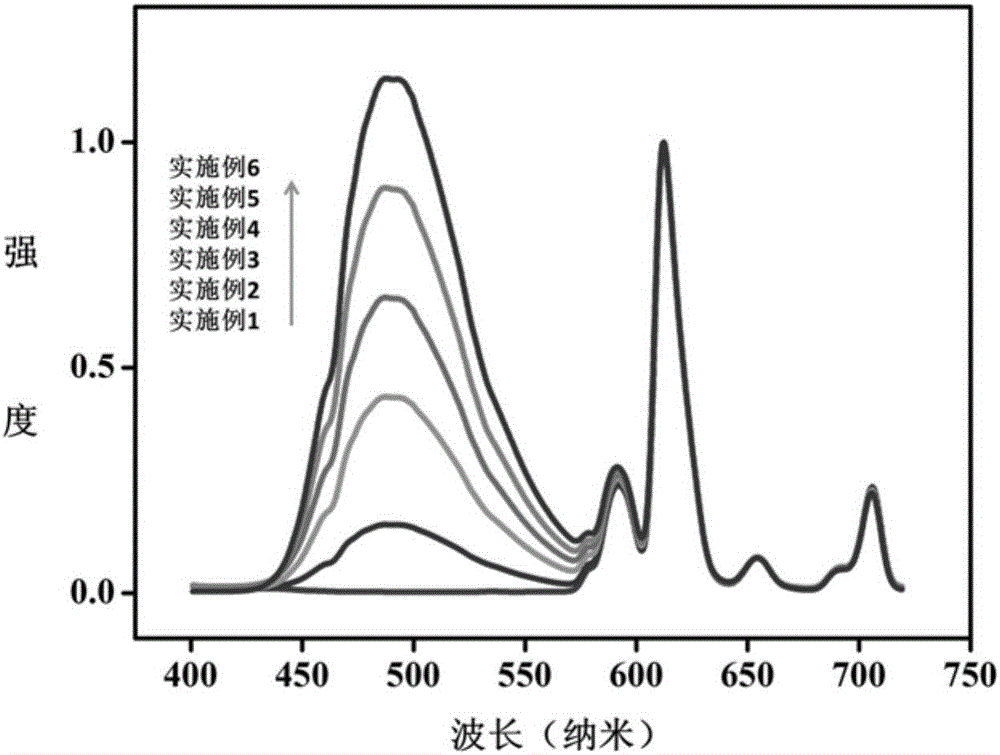

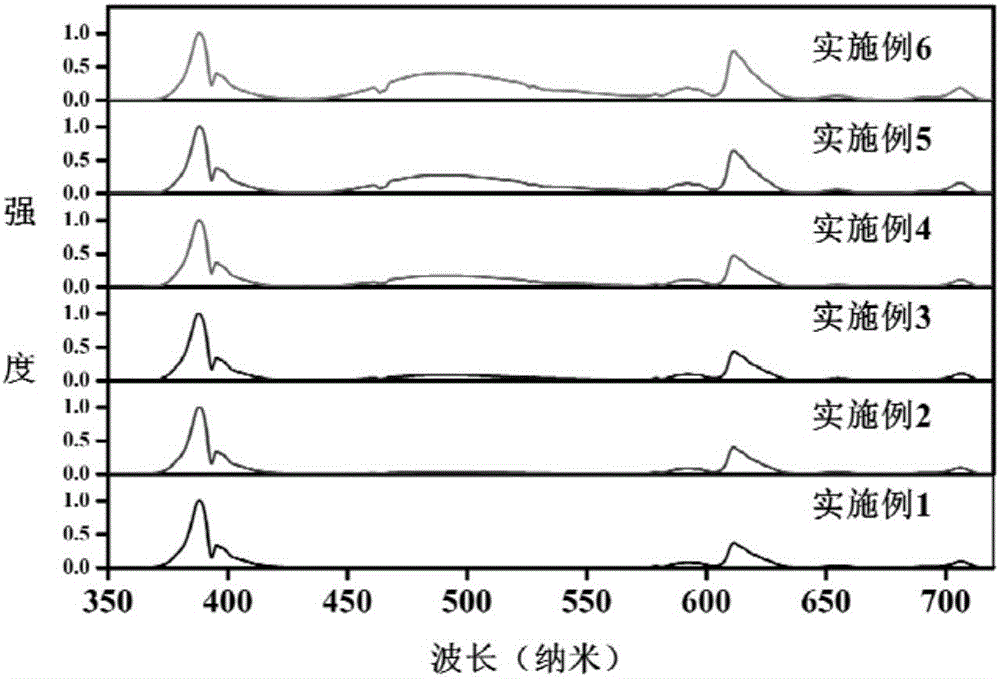

Embodiment 1

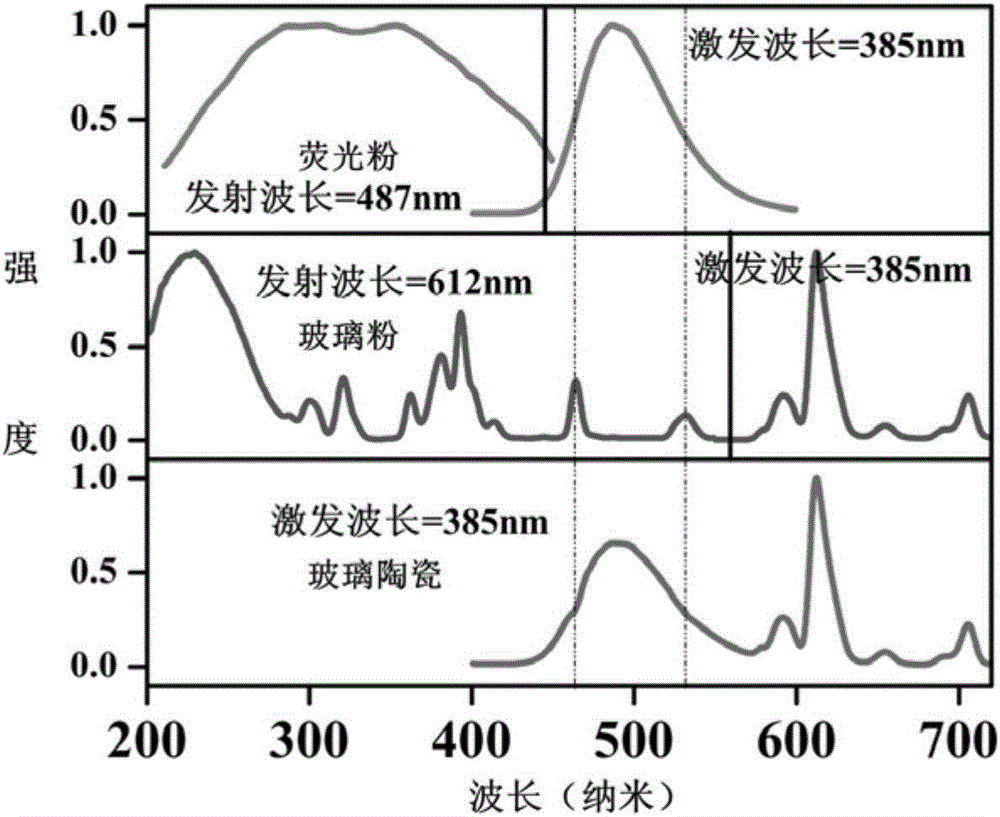

[0037] According to the mole percentage of each raw material in the silicate red luminous glass powder, according to 60% SiO 2 , 20% Na 2 CO 3 , 9% Al 2 o 3 , 6% CaO, 5% Eu 2 o 3 Fully mix the proportions, place in a high-temperature box-type resistance furnace, heat up to 1300°C at 5°C / min, keep warm for 3 hours, cool to room temperature with the furnace, and grind to obtain silicate red luminescent glass powder.

[0038] According to glass powder and Sr 4 Al 14 o 25 :Eu 2+ The mass percentage of phosphor powder is 100:0, mixed thoroughly, pressed into tablets under 20MPa pressure, placed in a high-temperature box-type resistance furnace, heated to 680°C at 5°C / min for sintering for 0.5h, then cooled to room temperature with the furnace, after After grinding and polishing, a luminescent glass ceramic is obtained.

[0039] The obtained luminescent glass ceramics are directly covered on the ultraviolet luminescent chip with an emission wavelength of 385nm, and the hig...

Embodiment 2

[0041] According to the mole percentage of each raw material in the silicate red luminous glass powder, according to 60% SiO 2 , 20% Na 2 CO 3 , 9% Al 2 o 3 , 6% CaO, 5% Eu 2 o 3 Fully mix the proportions, place in a high-temperature box-type resistance furnace, heat up to 1300°C at 5°C / min, keep warm for 3 hours, cool to room temperature with the furnace, and grind to obtain silicate red luminescent glass powder.

[0042] According to glass powder and Sr 4 Al 14 o 25 :Eu 2+ The mass percentage of the phosphor powder is 99.9:0.1, mixed thoroughly, pressed into tablets under a pressure of 20MPa, placed in a high-temperature box-type resistance furnace, heated to 680°C at 5°C / min for sintering for 0.5h, and then cooled to room temperature with the furnace. After grinding and polishing, the luminous glass ceramics are obtained.

[0043] The obtained luminescent glass ceramics are directly covered on the ultraviolet luminescent chip with an emission wavelength of 385nm, ...

Embodiment 3

[0045] According to the mole percentage of each raw material in the silicate red luminous glass powder, according to 60% SiO 2 , 20% Na 2 CO 3 , 9% Al 2 o 3 , 6% CaO, 5% Eu 2 o 3 Fully mix the proportions, place in a high-temperature box-type resistance furnace, heat up to 1300°C at 5°C / min, keep warm for 3 hours, cool to room temperature with the furnace, and grind to obtain silicate red luminescent glass powder.

[0046] According to glass powder and Sr 4 Al 14 o 25 :Eu 2+ The mass percentage of phosphor powder is 99.7:0.3, mixed thoroughly, pressed into tablets under 20MPa pressure, placed in a high-temperature box-type resistance furnace, heated to 680°C at 5°C / min for sintering for 0.5h, then cooled to room temperature with the furnace, after After grinding and polishing, the luminous glass ceramics are obtained.

[0047] The obtained luminescent glass ceramics are directly covered on the ultraviolet luminescent chip with an emission wavelength of 385nm, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com