Bovine bone collagen peptide preparation method

A collagen peptide, bovine bone technology, applied in the direction of animal/human protein, specific peptide, connective tissue peptide, etc., can solve the problems of long production cycle, easy browning, high energy consumption, etc., to achieve low energy consumption and shorten production Cycle, the effect of broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

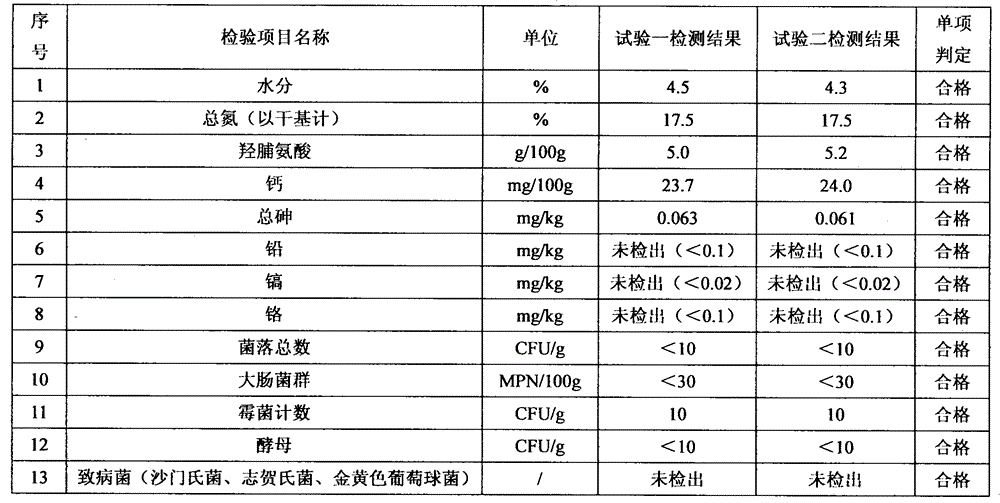

Examples

specific Embodiment approach 1

[0042] Specific embodiment one: this embodiment is a kind of preparation method of bovine bone collagen peptide, specifically is finished according to the following steps:

[0043] 1. Screening: According to the raw material acceptance standards and inspection procedures, the purchased fresh beef bone raw materials are inspected;

[0044] 2. Primary crushing: Put the screened fresh beef bones into the bone crusher and crush them into 5-8cm 3 Size and weigh bone fragments;

[0045] 3. Secondary crushing: place the broken bone in step 2 in a bone clay machine for crushing;

[0046] The bone slime machine described in step 3 adopts a 40-mesh stainless steel round hole screen;

[0047] 4. Cleaning: Wash the broken bones in a bone washing machine for 30-40 minutes, and soak them in clean water for 2-3 hours to extract the residual blood and drain them;

[0048] 5. High-temperature extraction: according to the mass ratio of crushed bone pieces to clear water 1: (3.5-4), place in ...

specific Embodiment approach 2

[0069] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: when extracting at high temperature in step 5, place it in a high-temperature extraction tank at a temperature of 120° C. Extract 2h. Others are the same as the first embodiment.

specific Embodiment approach 3

[0070] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: when reboiling in the second step in step six, put it in the high-temperature extraction tank again according to the mass ratio of bone mud and clear water of 1: 3.1, at a temperature of Extract at 115°C for 2h. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com