Method for cleaning treatment of hydrogen-containing tail gas and comprehensive recycling of antimony through antimony-containing alkaline leaching solution

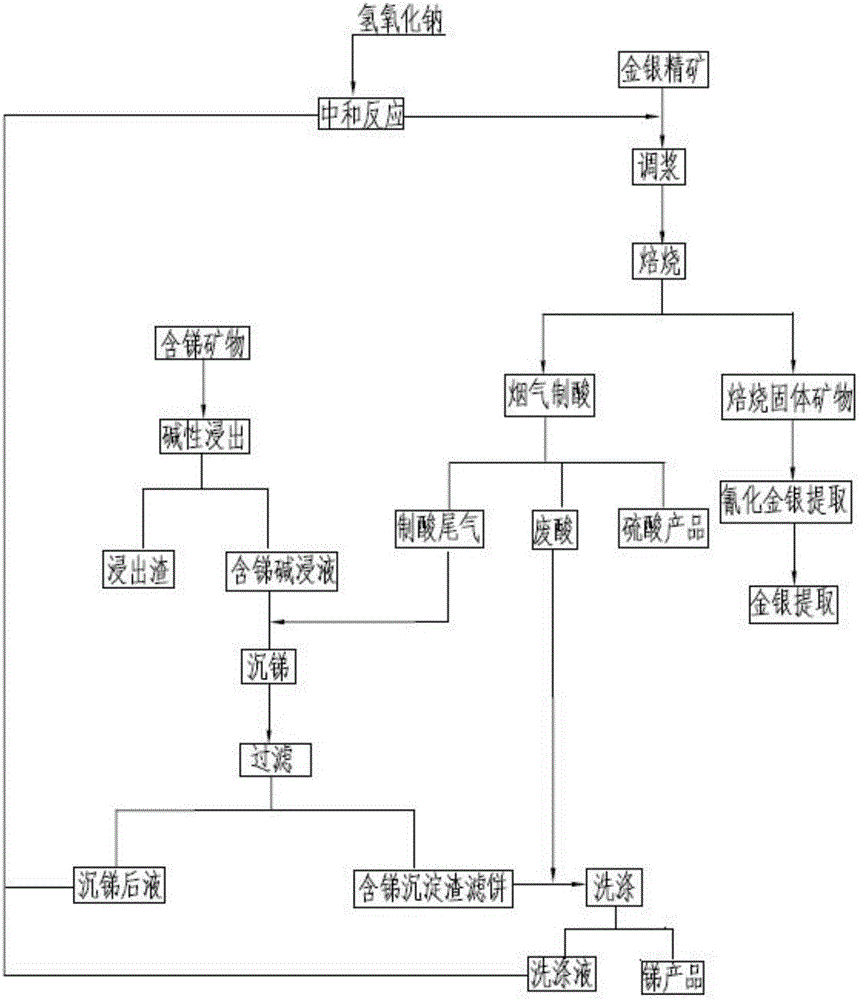

A technology of cleaning treatment and alkaline leaching solution, which is applied in the field of antimony-containing concentrate treatment, waste gas treatment and environmental protection, and waste liquid in the chemical industry. It can solve problems such as complex process flow, impact on the surrounding environment, and consumption of sulfuric acid, so as to improve economic benefits. , The process is simple and the effect of reducing pollution hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for comprehensively recovering antimony by cleaning and treating acid-making tail gas with antimony-containing alkali immersion liquid, comprising the following steps: 1) generating acid-making waste tail gas: adding gold and silver concentrate containing 15wt% sulfur and 100g / t silver to step 5 ) for the final treated liquid obtained in the slurry, the pulp concentration of the slurry is 50wt%, and the roasting flue gas and dusty flue gas produced by the roasting acid production process are purified by SO 2 , dry SO 2 , two conversions of SO 2 , After the secondary absorption, 98% of sulfuric acid products and SO containing 2 +SO 3 A total of 0.08vol% of acid production tail gas and 1wt% sulfuric acid concentration of waste acid (dilute acid), acid production tail gas enters the tail gas absorption system, waste acid (dilute acid) enters the dilute acid storage tank, and solid minerals obtained by roasting enter the gold and silver In the extraction process...

Embodiment 2

[0034] A method for comprehensively recovering antimony by cleaning and treating acid-making tail gas with antimony-containing alkali immersion liquid, comprising the following steps: 1) generating acid-making waste tail gas: adding gold and silver concentrate containing 30wt% sulfur and 520g / t silver to step 5 ) to prepare the final treated liquid, the slurry concentration of which is 62wt%, and the roasting flue gas and dust-containing flue gas produced by roasting acid production process are purified by SO2 , dry SO 2 , two conversions of SO 2 , After the secondary absorption, 98% of sulfuric acid products and SO containing 2 +SO 3 A total of 0.10vol% of acid production tail gas and 2wt% sulfuric acid concentration of waste acid (dilute acid), acid production tail gas enters the tail gas absorption system, waste acid (dilute acid) enters the dilute acid storage tank, and solid minerals obtained by roasting enter the gold and silver In the extraction process, the solid min...

Embodiment 3

[0040] A method for comprehensively recovering antimony from acid-making tail gas by cleaning and treating acid-making tail gas with antimony-containing alkali immersion liquid, comprising the following steps: 1) generating acid-making waste tail gas: adding gold and silver concentrate containing 50wt% sulfur and 1000g / t silver to step 5 ) to adjust the slurry, the slurry concentration of the slurry is 70wt%, and the roasting flue gas and dusty flue gas produced by the roasting acid production process are purified by SO 2 , dry SO 2 , two conversions of SO 2 , After the secondary absorption, 98% of sulfuric acid products and SO containing 2 +SO 3 A total of 0.12vol% of acid production tail gas and 2wt% sulfuric acid concentration of waste acid (dilute acid), acid production tail gas enters the tail gas absorption system, waste acid (dilute acid) enters the dilute acid storage tank, and solid minerals obtained by roasting enter the gold and silver In the extraction process, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com