Self-luminous reflecting film and preparation method thereof

A reflective film and self-illuminating technology, which is applied to illuminated marks, reflective reflectors, reflective/signal coatings, etc., can solve the problems of inability to achieve a good recognition effect, achieve good recognition, and the preparation method is simple. Effect of reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

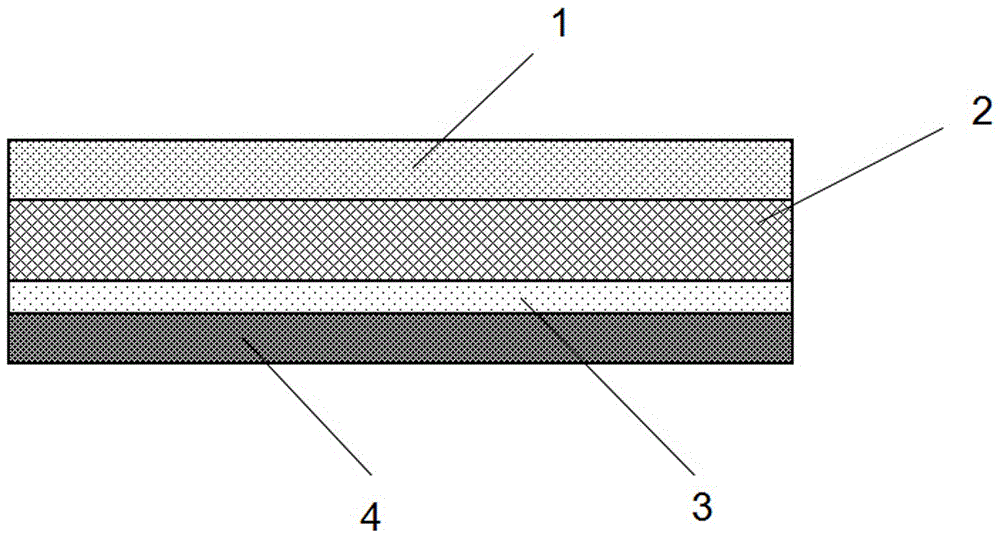

[0023] Such as figure 1 As shown, a self-illuminating reflective film includes a substrate 4, a reflective layer 3, a reflective-light storage layer 2, and a surface layer 1 from bottom to top; The reflective material mold with a microprism array structure is formed after being cured by ultraviolet lamps, and then peeled off from the mold. The thickness of the reflective-light-storing layer is 0.8mm.

[0024] The raw material composition of described printing ink is counted as: 45 parts of polyurethane acrylates, 30 parts of 2-phenoxy ethyl acrylates, initiator (2-hydroxyl-2-methyl-1-phenylacetone and 2 -Dimethylamino-2-benzyl-1-[4-(4-morpholinyl)phenyl]-1-butanone mixed at a mass ratio of 1:1) 8 parts, 0.8 parts of multifunctional epoxy acrylate and 20 parts of rare earth aluminate.

[0025] The method for the above-mentioned self-illuminating reflective film specifically comprises the following steps:

[0026] (1) Coat the ink on the reflective material mold with a microp...

Embodiment 2

[0031] A self-illuminating reflective film, which includes a base material, a reflective layer, a reflective-light-storage layer and a surface layer from bottom to top; On the material mold, it is made after being cured and shaped by ultraviolet light irradiation, and then peeled off from the mold. The thickness of the reflective-light-storing layer is 0.1mm.

[0032] The raw material composition of described ink is counted as: 38 parts of epoxy acrylates, 23 parts of alkyd modified acrylate resins, 3 parts of 1-hydroxycyclohexyl phenyl ketones, 0.1 parts of acid functional group monoacrylates and Zinc sulfide rare earth 15 parts.

[0033] The method for the above-mentioned self-illuminating reflective film specifically comprises the following steps:

[0034] (1) Coat the ink on the reflective material mold with a microprism array structure coated with a metal coating, then cover the upper layer and press it, and then irradiate it with an ultraviolet lamp (γ-ray) for 3 second...

Embodiment 3

[0039] A self-illuminating reflective film, which includes a base material, a reflective layer, a reflective-light-storage layer and a surface layer from bottom to top; On the material mold, it is made after being cured and shaped by ultraviolet light irradiation, and then peeled off from the mold. The thickness of the reflective-light-storing layer is 0.3mm.

[0040] The raw material composition of described printing ink is counted as: 40 parts of polyester acrylates, 25 parts of hexanediol diacrylates, 2-methyl-2-(4-morpholinyl)-1-[4-( 5 parts of methylthio)phenyl]-1-acetone, 0.3 parts of polydimethylsiloxane and 25 parts of rare earth aluminates.

[0041] The method for the above-mentioned self-illuminating reflective film specifically comprises the following steps:

[0042] (1) Coat the ink on the reflective material mold with a microprism array structure coated with a metal coating, then cover the upper layer and press it, and then irradiate it with an ultraviolet lamp (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com