Method for improving whiteness of Eucheuma muricatum algae powder

A technology of kylin cabbage and whiteness is applied in the field of improving the whiteness of kylin algae powder, which can solve the problems of darker, yellowish color and blackening of kylin cabbage powder, and achieve the effect of improving whiteness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

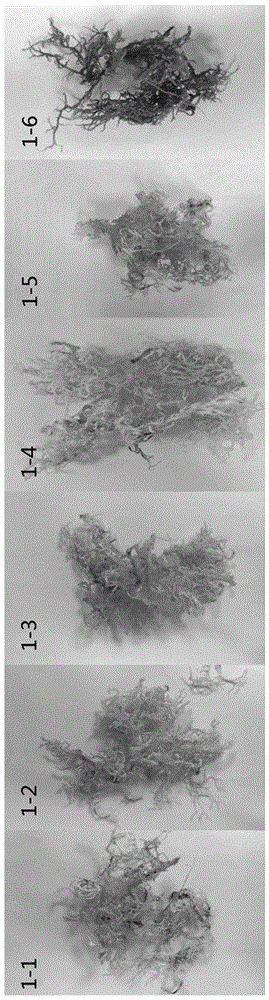

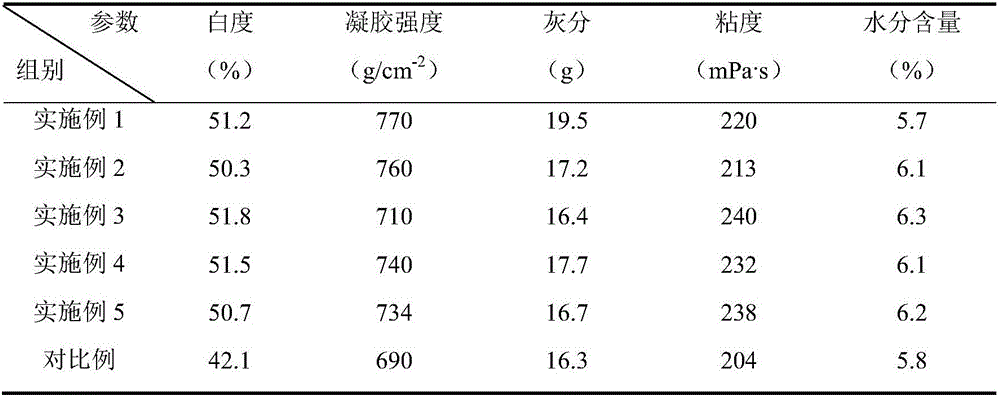

[0025] Take 30g of Eucheuma, wash it with 500g of water, add 600g of a compound solution with a mass concentration of 9% sodium hydroxide and 11% potassium chloride, treat it at 55°C for 4 hours, wash it with water until the pH is 7, and acidify with 0.01% hydrochloric acid After Eucheuma 0.1h (solid-liquid ratio is 1:1), add mass fraction of 0.1% sodium hypochlorite for 2h (solid-liquid ratio is 1:1). After adding 95% ethanol to the described Eucheuma and treating it for 1h (the ratio of solid to liquid is 1:15), it was placed in the sun and exposed to the sun until it dried to obtain the color of Eucheuma ( Picture 1-1 ) compared to the proportional color ( figure 1 -6) Obvious whiteness, crush Eucheuma to 80 meshes, use a whiteness colorimeter to measure the whiteness, and the whiteness is 51.2%, which is 21.6% higher than that of the comparative example.

Embodiment 2

[0027] Take 30g of Eucheuma, wash it with 1500g of water, add 700g of a compound solution with a mass concentration of 10% sodium hydroxide and 12% potassium chloride, treat it at 70°C for 4 hours, wash it with water until the pH is 7, and acidify with 0.02% acetic acid After Eucheuma 0.1h (solid-liquid ratio is 1:20), add mass fraction of 0.2% sodium hypochlorite for 1h (solid-liquid ratio is 1:30). After adding 40% ethanol to the Eucheuma chinensis for 8 hours (the ratio of solid to liquid is 1:15), it was exposed to the sun until dry. Get the Eucheuma color ( figure 1 -2) Contrast ratio color ( figure 1 -6) Obvious whiteness, the Eucheuma was crushed to 80 mesh, and the whiteness was measured by a whiteness colorimeter, and the whiteness was 50.3%, which was 19.5% higher than that of the comparative example.

Embodiment 3

[0029] Take 30g of Eucheuma, wash it with 500g of water, add 600g of a compound solution with a mass concentration of 11% sodium hydroxide and 12% potassium chloride, treat it at 60°C for 6 hours, wash it with water until the pH is 7, and acidify with 0.01% oxalic acid After Eucheuma 1h (solid-liquid ratio is 1:50), add mass fraction of 0.1% sodium hypochlorite for 2h (solid-liquid ratio is 1:20). After adding 85% ethanol to the Eucheuma chinensis for 4 hours (the ratio of solid to liquid is 1:5), it was exposed to the sun until dry. Get the Eucheuma color ( figure 1 -3) Contrast ratio color ( figure 1 -6) Obvious whiteness, the Eucheuma was crushed to 80 mesh, and the whiteness was measured by a whiteness colorimeter, and the whiteness was 51.8%, which was 23.0% higher than that of the comparative example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com