Injectable extracellular cartilage matrix particle and application of particle to implants

A decellularized cartilage and implant technology, applied in the field of regenerative medicine, can solve the problems of large particle size, weakened cosmetic repair effect, injection, etc., achieve good biocompatibility, good cosmetic repair effect, and reduce immune rejection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

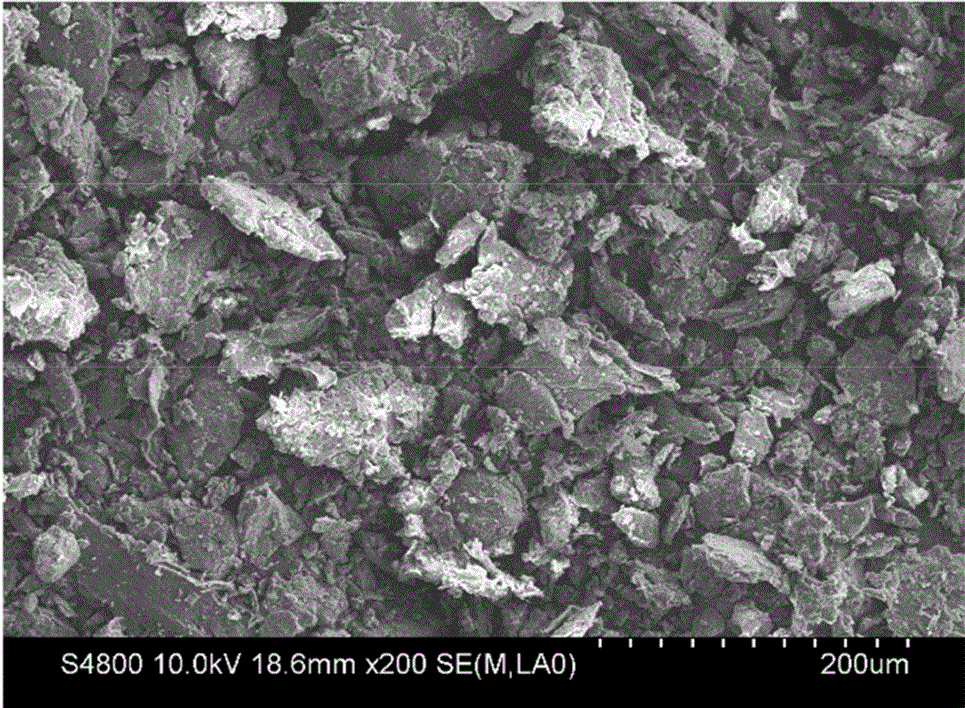

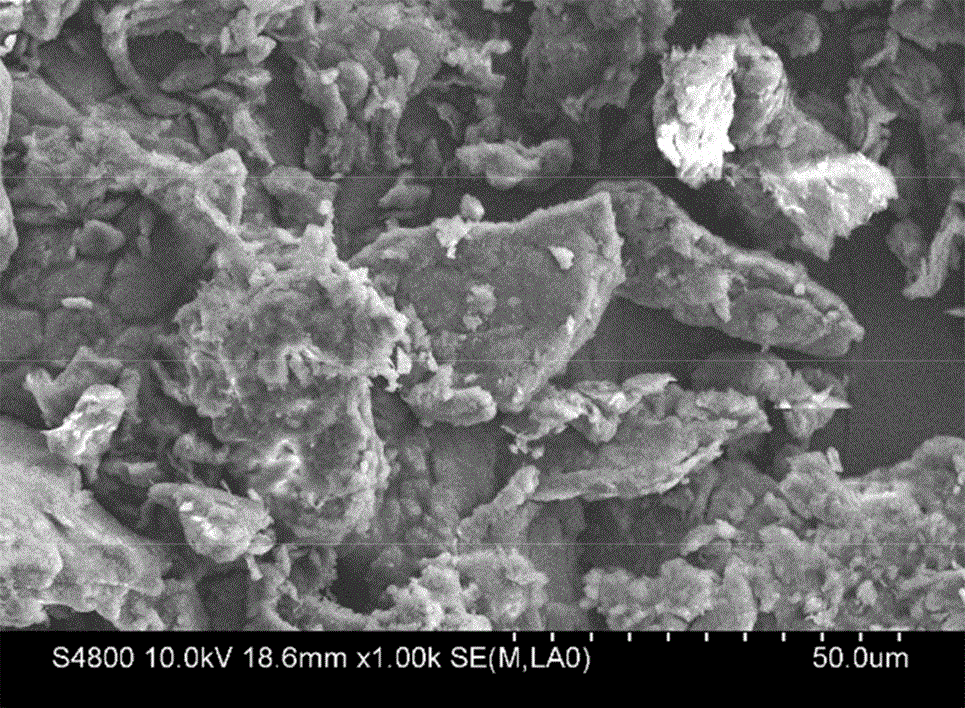

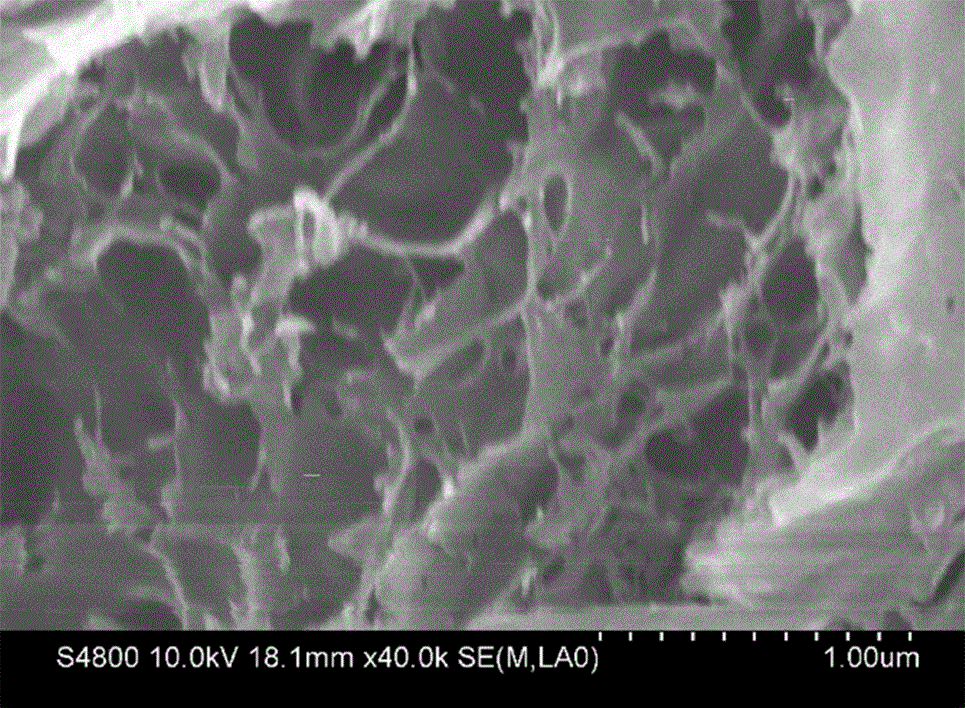

Image

Examples

Embodiment 1

[0048] The preparation method of injectable decellularized cartilage matrix microparticles comprises the following steps:

[0049] 1) Take bovine cartilage, rinse it in PBS solution for 3 times, sterilize the cartilage with 75% ethanol aqueous solution for 30 minutes, rinse it in PBS solution for 3 times, and then place the cartilage in a -80°C refrigerator Freeze for 2 hours, thaw at 37°C for 0.5 hours, repeat the process of freezing and thawing 3 times;

[0050]2) Cut the obtained cartilage into thin slices, the thickness of which is not more than 2mm, soak the cartilage thin slices in 1mM potassium chloride solution for 3h;

[0051] 3) Soak the obtained cartilage slices in 0.01M sodium hydroxide aqueous solution containing 0.5MEDTA for 12h, the volume ratio of the cartilage slices to the solution is 1:50, rinse with PBS solution for 3 times; then place the cartilage slices in 0.5M HCl Soak the cartilage slices in 1M sodium chloride aqueous solution for 8 hours, the volume ...

Embodiment 2

[0057] The preparation method of injectable decellularized cartilage matrix microparticles comprises the following steps:

[0058] 1) Take pig cartilage, rinse it in PBS solution for 4 times, disinfect the cartilage with 0.5% peracetic acid aqueous solution for 30 minutes, rinse it in PBS solution for 3 times, and put the cartilage in a -80°C refrigerator Freeze in medium for 2h, thaw at 37°C for 0.8h, repeat freezing and thawing 3 times;

[0059] 2) Cut the obtained cartilage into thin slices, the thickness of which is not more than 2mm, soak the cartilage thin slices in 2mM potassium chloride solution for 4h;

[0060] 3) Soak the obtained cartilage slices in 0.01M sodium hydroxide solution containing 1MEDTA for 14h, the volume ratio of the cartilage slices to the solution is 1:60, rinse with PBS solution for 3 times; then place the cartilage slices in 0.6M HCl containing 1M Soak in sodium chloride solution for 8 hours, the volume ratio of cartilage slices to solution is 1:6...

Embodiment 3

[0066] The preparation method of injectable decellularized cartilage matrix microparticles comprises the following steps:

[0067] 1) Take bovine animal cartilage, rinse it in PBS solution for 3 times, disinfect the cartilage with 75% ethanol aqueous solution for 10 minutes, and then disinfect the cartilage with 0.2% peracetic acid aqueous solution for 20 minutes Minutes, rinsed in PBS solution for 3 times, then placed the cartilage in a -80°C refrigerator for 1.5h, thawed at 37°C for 0.5h, and repeated freezing and thawing 3 times;

[0068] 2) Cut the obtained cartilage into thin slices, the thickness of which is not more than 2mm, and soak the cartilage thin slices in 1.5 mM potassium chloride solution for 5 hours;

[0069] 3) Soak the obtained cartilage slices in 0.01M sodium hydroxide solution containing 1MEDTA for 12h, the volume ratio of the cartilage slices to the solution is 1:50, rinse with PBS solution for 3 times; then place the cartilage slices in 1M chlorine conta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com