Preparation method of titanium dioxide nanosheet-diatomite composite photocatalyst

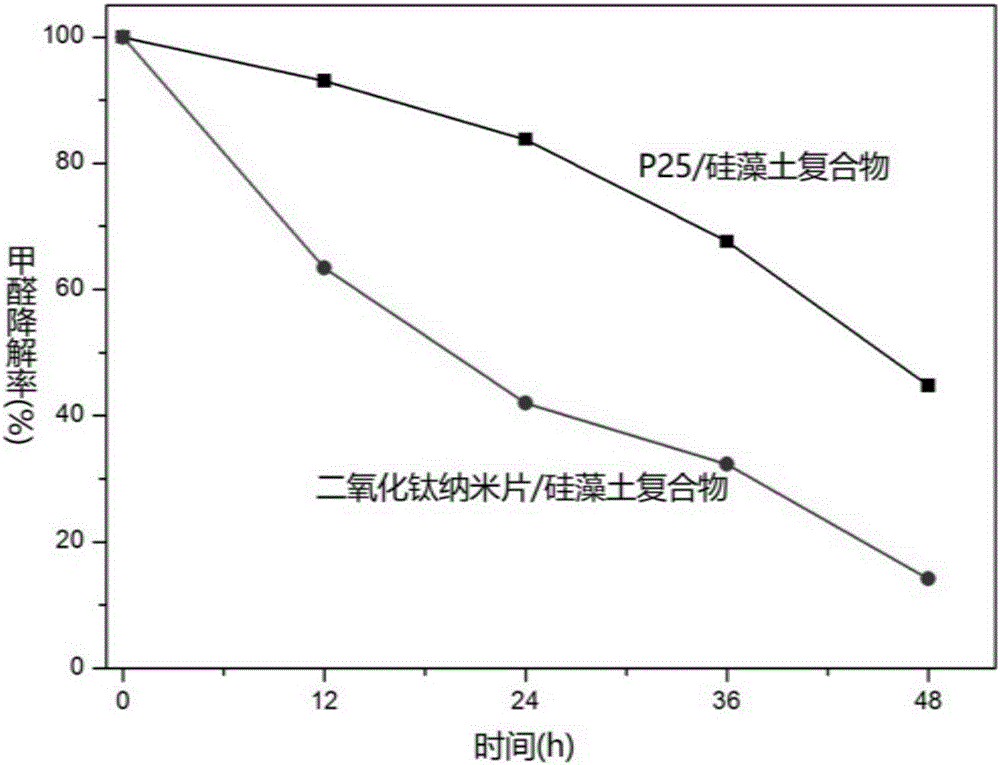

A technology of titanium dioxide and diatomaceous earth, applied in physical/chemical process catalysts, chemical instruments and methods, separation methods, etc., can solve the problems of reducing the degradation efficiency of formaldehyde gas, low photocatalytic efficiency, etc., to improve efficiency and improve refractive performance. , Enhance the effect of pearlescent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] An embodiment of the present invention provides a method for preparing a titanium dioxide nanosheet and diatomite composite photocatalyst, comprising:

[0016] Diatomaceous earth pretreatment:

[0017] Pickling treatment of diatomite: put diatomite in a container, add deionized water, then add concentrated hydrochloric acid, reflux reaction for 5h under magnetic stirring, then suction filter, wash with deionized water and absolute ethanol respectively Three times until there is no chloride ion, vacuum-dry at 100°C, and obtain pretreated diatomite after drying;

[0018] Preparation of composite photocatalyst:

[0019] Disperse the pretreated diatomite in absolute ethanol, add titanium tetraisopropoxide, transfer it to a polytetrafluoroethylene-lined hydrothermal reactor, and then add it dropwise to the reactor with a mass concentration of 40% hydrofluoric acid, seal the polytetrafluoroethylene-lined hydrothermal reaction kettle, keep it warm at 160-220°C for 24-50 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com