Cationic-emulsion-particle-toughened hydrophobic association hydrogel and preparing method

A technology of cationic emulsion and hydrophobic association, applied in the field of cationic emulsion particle toughening hydrophobic association hydrogel and preparation method, can solve the problem of hydrogel toughening and the like, and achieve the effect of strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 A hydrophobic association hydrogel toughened by cationic emulsion particles, the composition and weight ratio are as follows: cationic emulsion particles: hydrophobic monomer: emulsifier: main monomer: deionized water: 0.6:0.5:3: 40:100;

[0030] Described cationic emulsion particle is prepared by following (1) method for preparing cationic emulsion particle;

[0031] Described hydrophobic monomer is hexadecyl methacrylate;

[0032] Described emulsifying agent is cetyl trimethyl ammonium chloride;

[0033] The main monomer is acrylamide.

[0034] A cationic emulsion particle toughened hydrophobic association hydrogel and the steps and conditions of the preparation method are as follows:

[0035] (1) Preparation of cationic emulsion particles

[0036] (a) Styrene was removed polymerization inhibitor with 5wt% sodium hydroxide solution, then washed to neutrality with deionized water, after drying with anhydrous magnesium sulfate, carry out vacuum distillatio...

Embodiment 2

[0058] Example 2 A cationic emulsion particle toughened hydrophobic association hydrogel, the composition and weight ratio are as follows: cationic emulsion particle: hydrophobic monomer: emulsifier: main monomer: deionized water: 0.4:0.6:3: 40:100;

[0059] Described cationic emulsion particle is prepared by following (1) method for preparing cationic emulsion particle;

[0060] Described hydrophobic monomer is hexadecyl methacrylate;

[0061] Described emulsifying agent is cetyl trimethyl ammonium chloride;

[0062] The main monomer is acrylamide.

[0063] A cationic emulsion particle toughened hydrophobic association hydrogel and the steps and conditions of the preparation method are as follows:

[0064] (1) Preparation of cationic emulsion particles

[0065] (a) with embodiment 1;

[0066] (b) According to the weight ratio of deionized water, styrene, cationic monomer p-vinylbenzyltrimethylammonium chloride, and cationic initiator azobisisobutylimidium hydrochloride i...

Embodiment 3

[0078] Example 3 A cationic emulsion particle toughened hydrophobic association hydrogel, the composition and weight ratio are as follows: cationic emulsion particle: hydrophobic monomer: emulsifier: main monomer: deionized water: 0.4:1:3: 40:100;

[0079] Described cationic emulsion particle is prepared by following (1) method for preparing cationic emulsion particle;

[0080] Described hydrophobic monomer is lauryl methacrylate;

[0081] Described emulsifier is cetyltrimethylammonium bromide;

[0082] The main monomer is acrylamide.

[0083] A cationic emulsion particle toughened hydrophobic association hydrogel and the steps and conditions of the preparation method are as follows:

[0084] (1) Preparation of cationic emulsion particles

[0085] (a) with embodiment 1;

[0086] (b) According to the weight ratio of deionized water, styrene, cationic monomer dimethyl diallyl ammonium chloride, and cationic initiator azobisisobutylimidazoline hydrochloride is 100:18:0.3: 0...

PUM

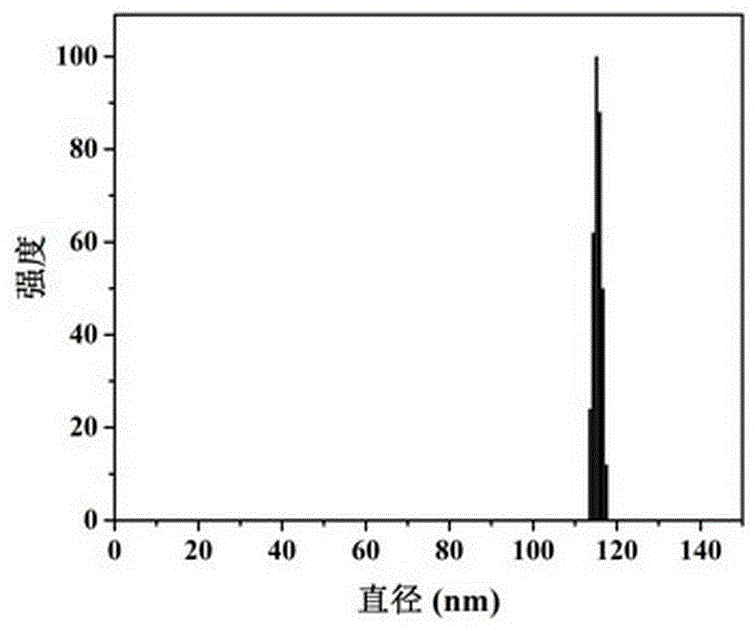

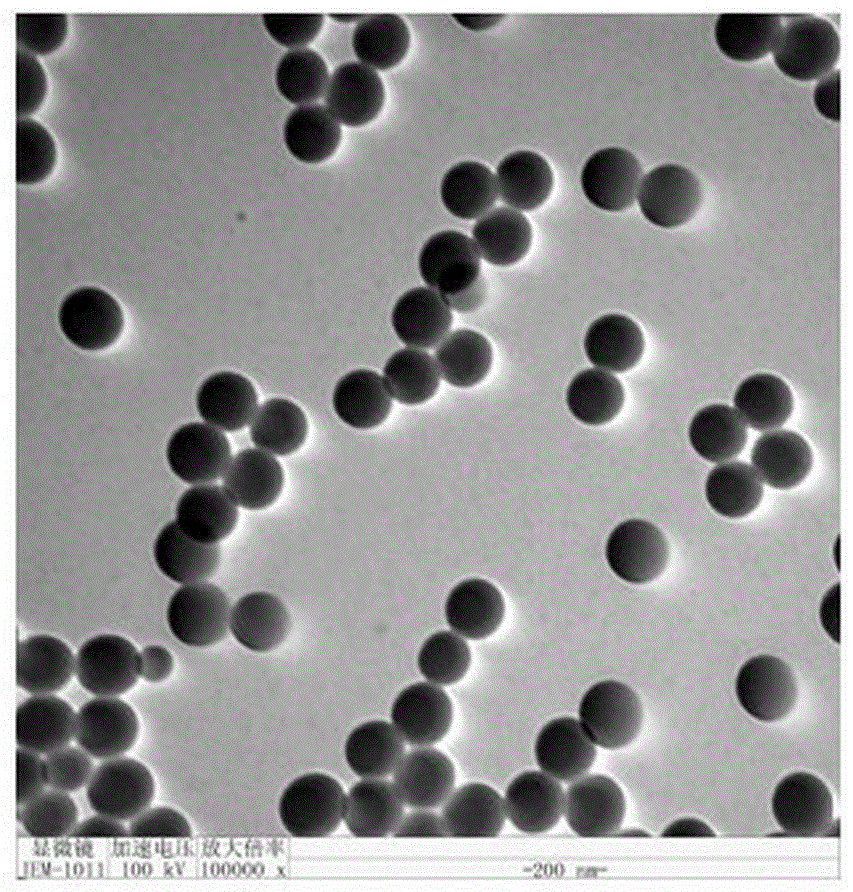

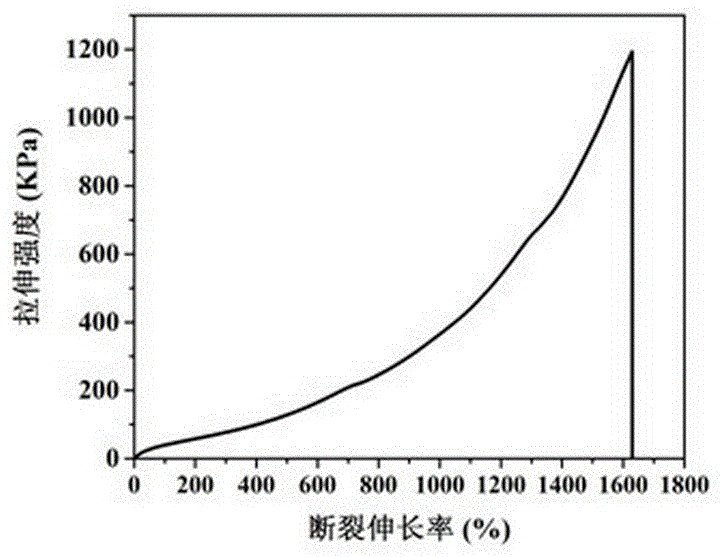

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com