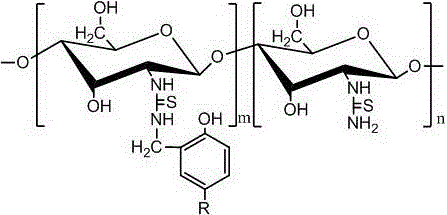

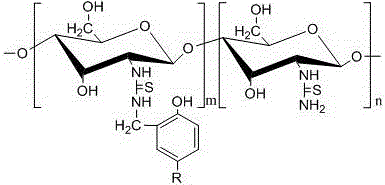

Chitosan-modified low-temperature epoxy resin curing agent and preparation method thereof

A technology of epoxy resin curing and chitosan modification, which is applied in the preparation of sugar derivatives, chemical instruments and methods, esterified saccharides, etc., can solve the problems of strong irritation, strong odor, and high toxicity of curing agents. Achieve obvious effect and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Preparation of low-molecular-weight chitosan: weigh 5g of chitosan in a 500ml beaker, then add 200ml of 10% acetic acid solution, heat the resulting mixed solution to 60°C, and use a power of 100w, ultrasonic frequency Place the probe of a 30Hz ultrasonic cell pulverizer in a beaker and degrade it for 30 hours. After the solution is cooled to room temperature, add 10% sodium solution dropwise to adjust the pH value to 7. Filter to remove the precipitate, and put the clear solution into a dialysis bag in distilled water. Dialyzed in medium for 24 hours, the solution was concentrated, ethanol was added to precipitate the precipitate, separated and dried in a vacuum oven at 50°C at low temperature to obtain low molecular weight chitosan, the reaction yield was 85%;

[0019] (2) Preparation of thiourea-modified amine: In a 250mL clean four-neck flask equipped with a stirring device, a condensing device, a tail gas absorption device for NaOH solution and a thermometer, ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com