Honeycomb type automobile combustion-supporting device, and preparation method and application thereof

A combustor, honeycomb technology, applied in mechanical equipment, machine/engine, combustion air/combustion-air treatment, etc., can solve the problems of increased fuel consumption, decreased kinetic energy, etc., to reduce fuel consumption, increase power, and reduce friction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

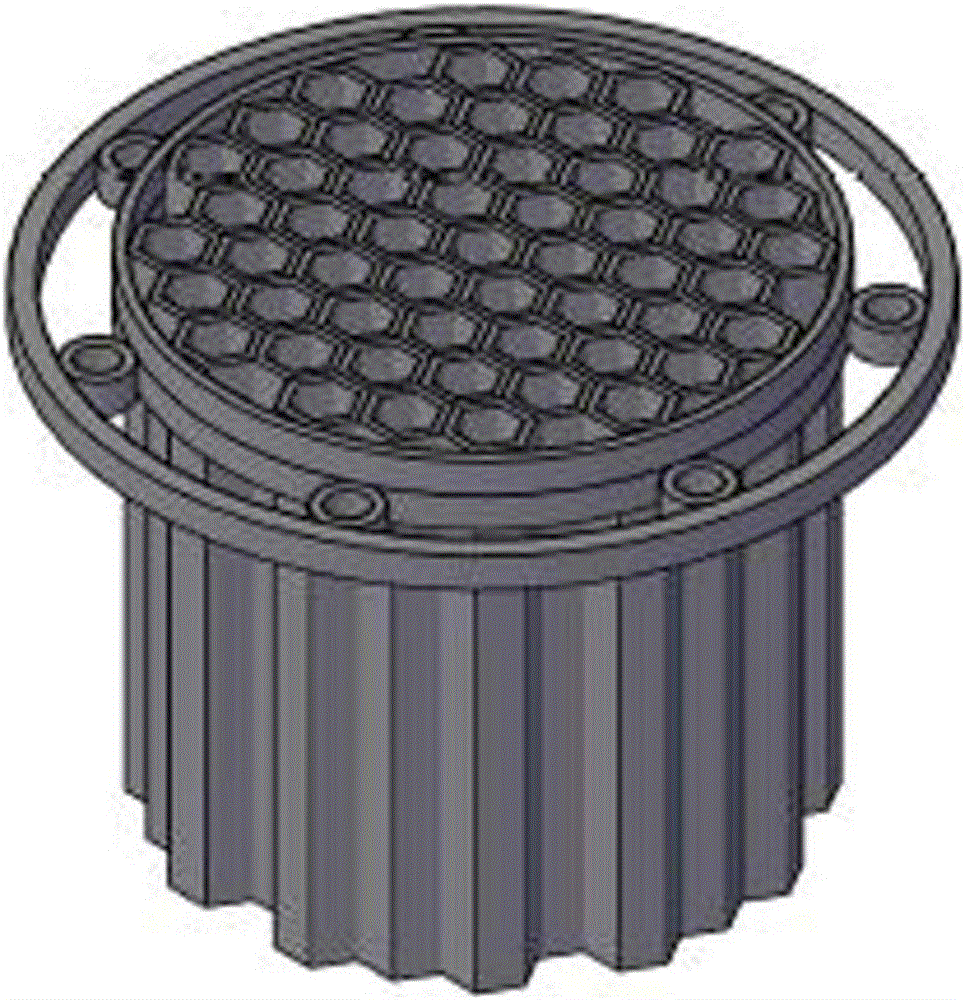

[0026] A kind of honeycomb car combustor, such as figure 1 As shown, the combustor is cylindrical, densely arranged with multiple honeycomb-shaped channels, the diameter of the channel is 0.1 to 1 cm, and the length of the channel is 3 to 10 cm.

[0027] The raw materials for the preparation of the honeycomb automobile combustor: 12 parts of glycidyl methacrylate grafted polyamide (GMA grafting ratio is 1.2%), 52 parts of polyamide resin, 2.2 parts of chelating compatibilizer, 6.0 parts of maleic anhydride Grafted polyolefin elastomer (purchased from Nanjing Sutai Polymer Technology Co., Ltd., MAH grafting ratio is about 1.2%) and 30 parts of inorganic integrated subphoton fluctuation powder; chelating compatibilizer is composed of 60wt% ethylenediaminetetraacetic acid It is composed of sodium metal, 25wt% stearic acid, 15wt% titanate; inorganic comprehensive subphoton fluctuation powder is composed of 88wt% kaolin, 10wt% titanium dioxide, 0.3wt% europium oxide, 0.6wt% ytterbium ...

Embodiment 2

[0030] The raw materials for the preparation of the honeycomb automobile combustor: 6 parts glycidyl methacrylate grafted polyamide (GMA grafting ratio is 0.9%), 48 parts polyamide resin, 0.6 parts chelating compatibilizer, 4.5 parts maleic anhydride Grafted polyolefin elastomer (MAH grafting ratio is about 1.0%) and 16 parts of inorganic comprehensive subphoton fluctuation powder; chelating compatibilizer is composed of 50wt% ethylenediaminetetraacetic acid potassium metal, 30wt% stearic acid, 20wt % Titanate; the inorganic integrated subphoton fluctuation powder is composed of 60wt% kaolin, 35wt% titanium dioxide, 1wt% europium oxide, 1.2wt% ytterbium oxide, 1.8wt% dysprosium oxide, and 1wt% holmium oxide.

[0031] The above raw materials are stirred and put into a mixing biaxial machine heated to 140-160°C, then mixed at 240-265°C, compressed into a film through a mold, and the mold material is cooled, cooled, and cut to obtain a honeycomb automobile combustor.

Embodiment 3

[0033] The raw materials for the preparation of the honeycomb automobile combustor: 18 parts of glycidyl methacrylate grafted polyamide (GMA grafting ratio is 1.5%), 60 parts of polyamide resin, 3.5 parts of chelating compatibilizer, 8.6 parts of maleic anhydride Grafted polyolefin elastomer (MAH graft ratio is about 1.5%) and 38 parts of inorganic comprehensive subphoton fluctuation powder; chelating compatibilizer is composed of 70wt% ethylenediaminetetraacetic acid calcium metal, 20wt% stearic acid, 10wt % Titanate composition; the inorganic comprehensive subphoton fluctuation powder is composed of 70wt% kaolin, 24.4wt% titanium dioxide, 2wt% europium oxide, 0.8wt% ytterbium oxide, 1wt% dysprosium oxide, 1.8wt% holmium oxide.

[0034] The above raw materials are stirred and put into a mixing biaxial machine heated to 140-160°C, then mixed at 240-265°C, compressed into a film through a mold, and the mold material is cooled, cooled, and cut to obtain a honeycomb automobile combus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com