Production method of low-temperature sterilized surimi products capable of being storage at room temperature

A technology for surimi products and production methods, which are applied in the direction of preservation of meat/fish by freezing/cooling, food science, etc., can solve excessive protein denaturation, limit the convenience of eating surimi products, and reduce the hardness, elasticity and gel of surimi products. Food indicators such as strength and nutritional indicators, to reduce damage, improve the quality of surimi gel, and increase nutritional value and edible value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

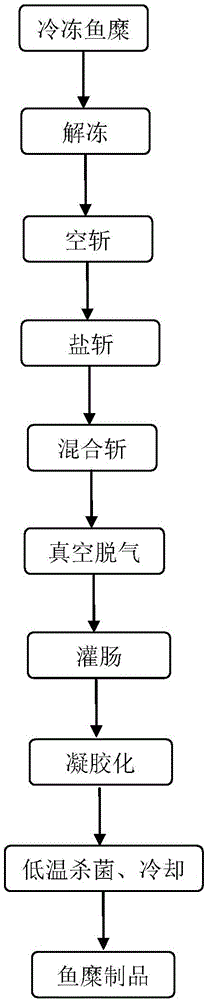

Method used

Image

Examples

Embodiment 1

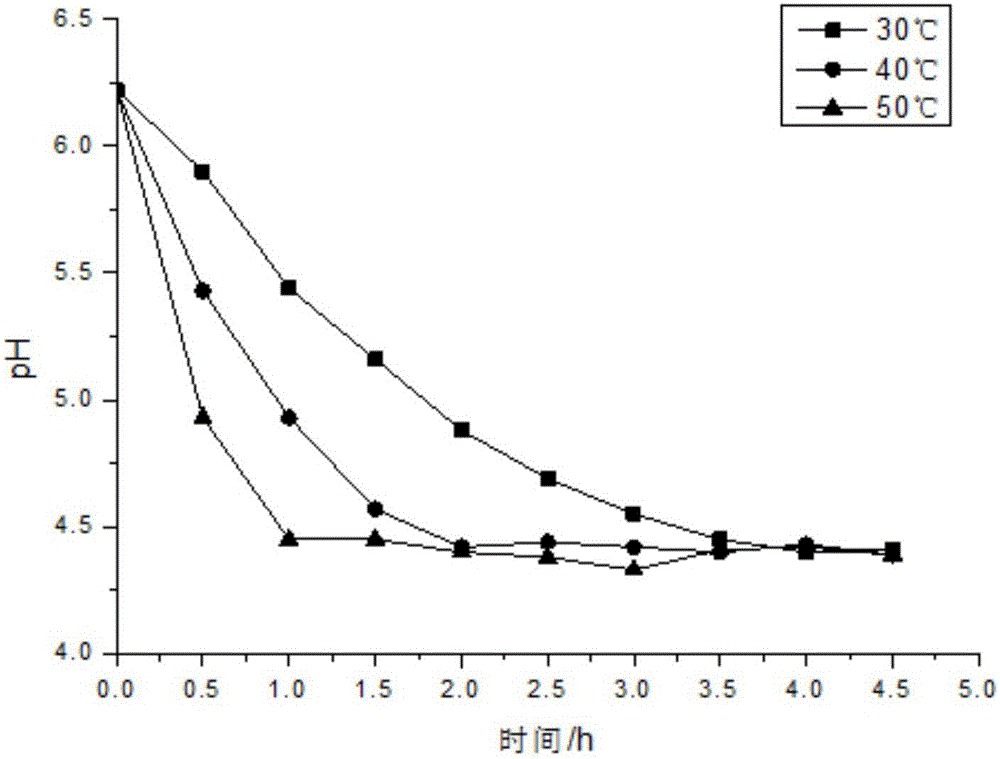

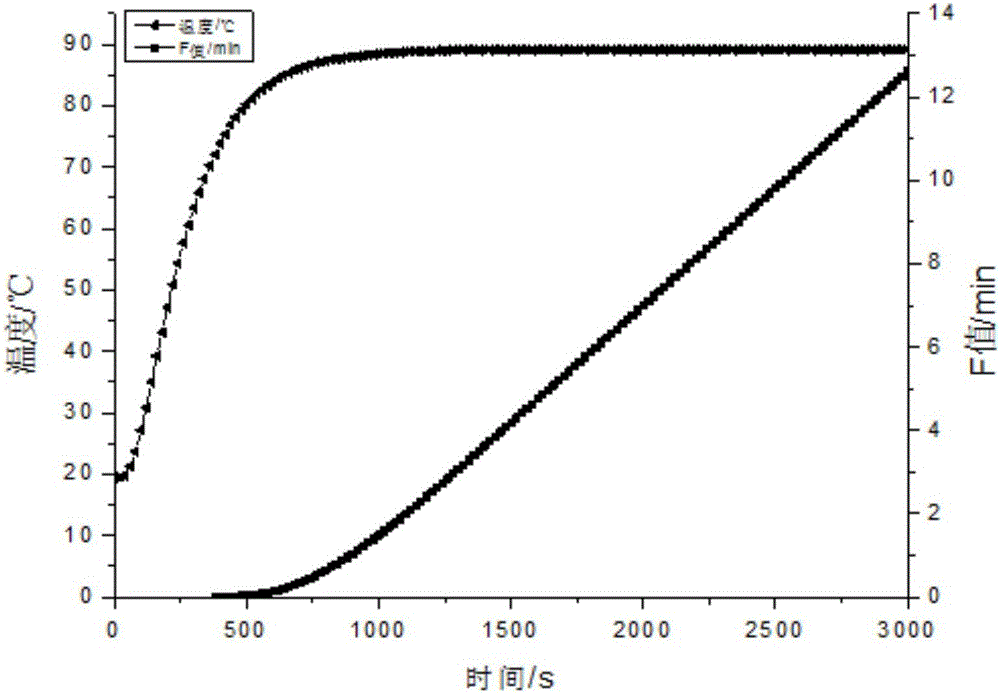

[0030] Thaw frozen crucian carp surimi at 4°C for 12 hours, weigh 300g of the thawed surimi, chop and mix for 5 minutes at a temperature lower than 10°C, then add salt with 2.0% of the mass of the surimi, chop and mix for 5 minutes, and finally add Surimi quality 1% soybean protein isolate, 5% potato hydroxypropyl distarch phosphate, 0.5% locust bean gum, 2% green onion ginger juice, 6% cooking wine, 0.5% white pepper powder, mix well , then add gluconolactone, mix and chop for 5 minutes, pay attention to continuously add crushed ice during the whole chopping process, the amount of crushed ice is 20% of the mass of surimi, and the amount of gluconolactone added is 2.0% of the total mass of the formula , Put the chopped surimi into a vacuum mixer and vacuum degassing while stirring. The vacuum degree is 0.08MPa, and the degassing time is 3min. Pour the degassed surimi into a casing with a diameter of 25mm, punch and seal, and form a package After it is ready, gelatinize at 30°C...

Embodiment 2

[0032] Thaw frozen herring surimi at 3°C for 12 hours, weigh 300g of the thawed surimi, chop and mix for 5 minutes at a temperature lower than 10°C, then add 2.5% of the mass of surimi, chop and mix for 4 minutes, and finally add Surimi quality 1% soybean protein isolate, 6% potato hydroxypropyl distarch phosphate, 0.5% locust bean gum, 2% green onion ginger juice, 7% cooking wine, 0.5% white pepper powder, mix well , then add gluconolactone, mix and chop for 7 minutes, pay attention to continuously add crushed ice during the whole chopping process, the amount of crushed ice is 20% of the mass of surimi, and the amount of gluconolactone added is 2.0% of the total mass of the formula , put the chopped surimi into a vacuum mixer and vacuum degassing while stirring, the vacuum degree is 0.08MPa, the degassing time is 3min, pour the degassed surimi into a casing with a diameter of 30mm, punch and seal, and form the package After it is ready, gelatinize at 30°C for 3.5 hours, tes...

Embodiment 3

[0034]Thaw the frozen grass carp surimi at 5°C for 10 hours, weigh 300g of the thawed surimi, chop and mix in air for 6 minutes at a temperature lower than 10°C, then add 2.5% of the mass of the surimi, chop and mix for 7 minutes, and finally add Surimi quality 2% soybean protein isolate, 5% potato hydroxypropyl distarch phosphate, 1% locust bean gum, 3% green onion ginger juice, 6% cooking wine, 1% white pepper, mix well , then add gluconolactone, mix and chop for 5 minutes, pay attention to continuously add crushed ice during the whole chopping process, the amount of crushed ice is 24% of the mass of surimi, and the amount of gluconolactone added is 2.0% of the total mass of the formula , Put the chopped surimi into a vacuum mixer and vacuum degassing while stirring. The vacuum degree is 0.10MPa, and the degassing time is 1.5min. Pour the degassed surimi into a casing with a diameter of 30mm, punch and seal, and shape After packaging, gelatinize at 35°C for 2 hours, test the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com