Flexible high-efficiency heat insulation material

A technology of thermal insulation and thermal insulation materials, which is applied in the direction of rigid containers, containers, boxes, etc., can solve the problems of short insulation and thermal insulation time, short service life, white pollution and other problems of thermal insulation materials, and achieve saving of packaging material costs, simple use, The effect of reducing carbon emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 discloses a polymer flexible high-efficiency thermal insulation material, which in turn includes: aluminum foil, woven fabric, multilayer EPE material, woven fabric, aluminum foil, wherein the above-mentioned woven fabric is PE made of polymer material Or PP woven cloth.

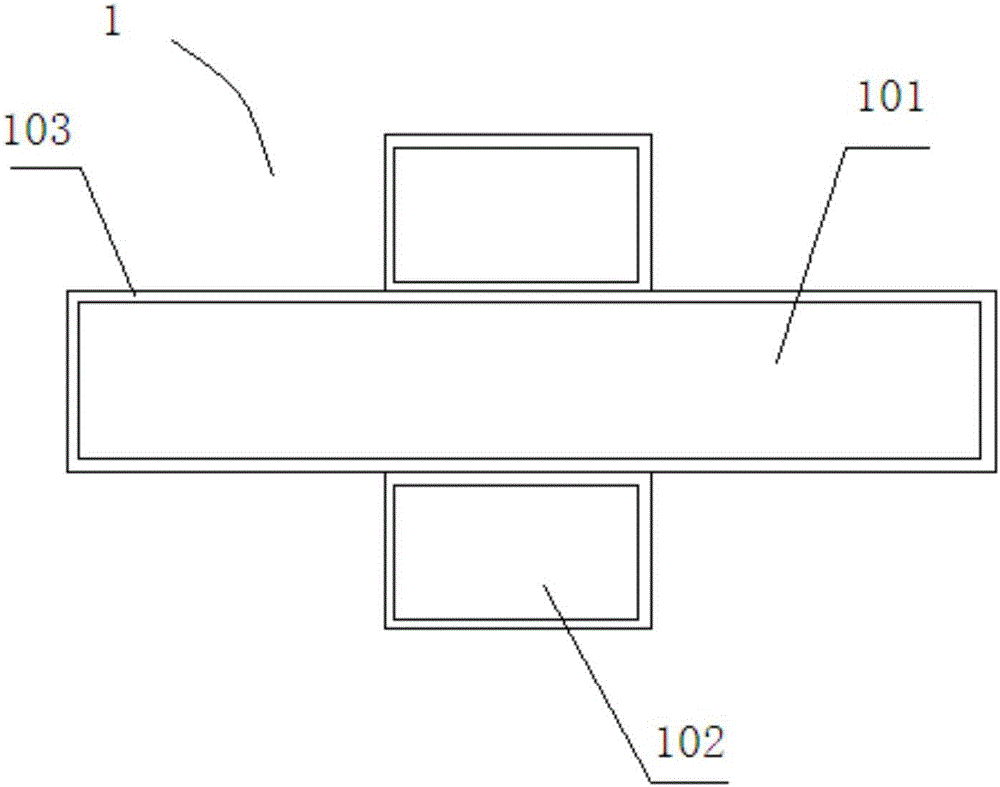

[0032] The thermal insulation material in Example 1 is prepared into a tray cover. The tray cover includes a cover bottom 2 and a cover body 1, such as figure 1 The cover body includes a rectangular body sheet structure 101, the two sides of the rectangular body sheet structure 101 are provided with fin structures 102 symmetrically, and the fin structure 102 is arranged on the long side of the rectangular body sheet structure 101, and It is arranged at the midline of the long side of the rectangular body sheet structure 101.

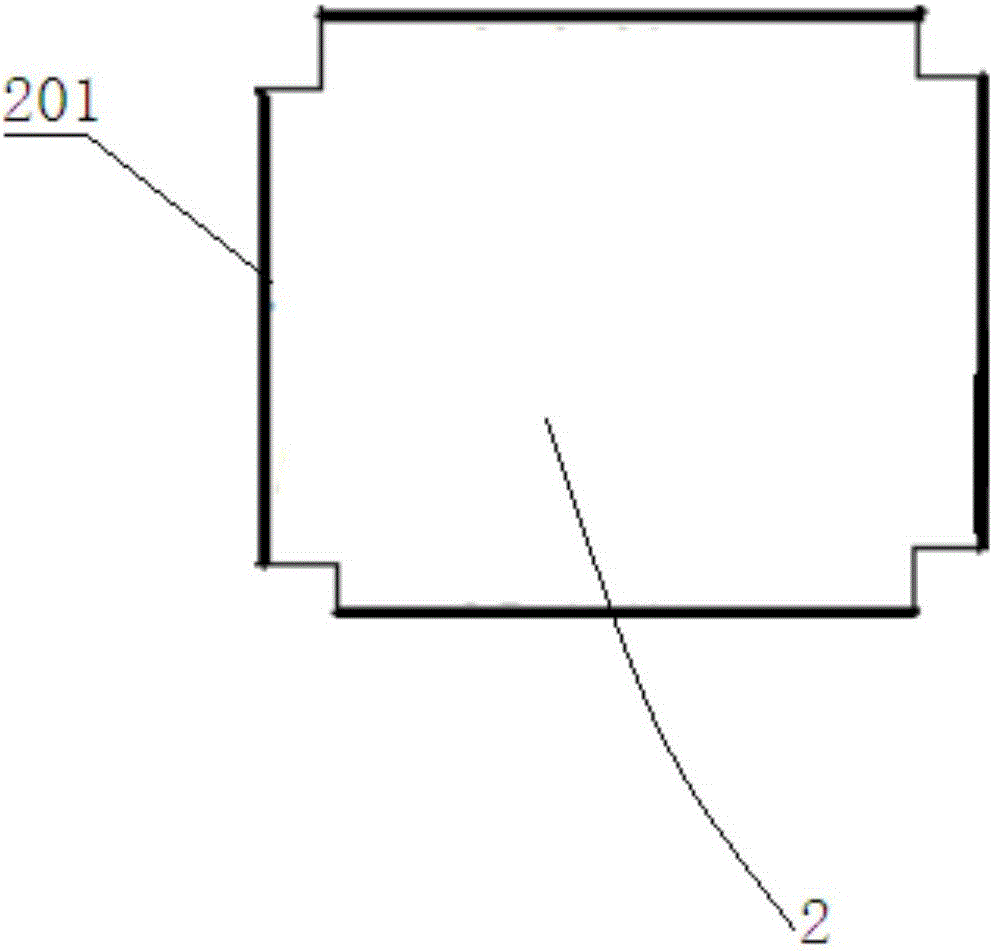

[0033] Such as figure 2 As shown in the figure, the above-mentioned cover bottom 2 has a rectangular structure, and the edges of the rectangular structure are all provi...

Embodiment 2

[0037] Embodiment 2 discloses a flexible high-efficiency thermal insulation material. The thermal insulation material includes nano-coating, aluminum foil, woven cloth, multi-layer EPE material, woven cloth, aluminum foil, and nano-coating. The woven cloth is nano-material and PE or PP made of polymer materials.

[0038] The above-mentioned nano materials include zirconium oxide and titanium oxide.

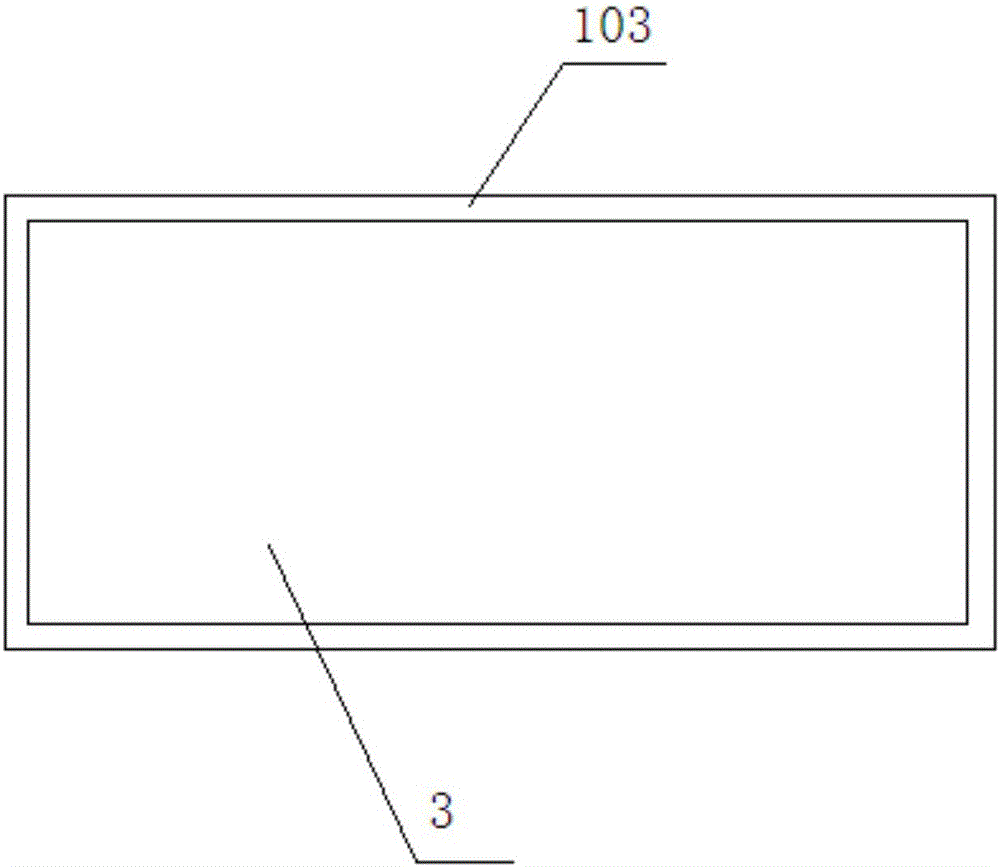

[0039] Such as image 3 As shown, the thermal insulation material is prepared into thermal insulation blanket 3, the edges of the thermal insulation blanket are sewn with a single layer of woven tape, and the width of the woven tape 103 is 3-10 cm.

[0040] The length of the above-mentioned insulation blanket is 1-100m, and the width is 0.1-3m. The edge of the insulation blanket 3 is sewn with a single layer of 3-10cm webbing, and the middle joint is sewn in two layers, and then wrapped with 3-10cm webbing. side.

Embodiment 3

[0042] Embodiment 3 discloses a flexible high-efficiency thermal insulation material, which in turn includes: nano-coating, aluminum foil, nano-woven fabric, multilayer nano-EPE material, woven fabric, aluminum foil, nano-coating, the above-mentioned woven fabric is nano PE or PP synthesized with polymer materials, or the above woven fabric is aerogel or PE or PP and EPE synthesized with phase change materials and polymer materials, and the above thermal insulation materials are prepared into thermal insulation cover / blanket / box / box , The length of the heat preservation cover is 0.1-2m, the width is 0.1-2m, and the height is 0.1-2m.

[0043] Wherein, the aforementioned nano material includes nano zirconia and nano titanium oxide.

[0044] The flexible high-efficiency heat insulation material in Examples 1-3 can be used exclusively in the cold chain transportation process. The material can be prepared into a heat preservation cover, a heat preservation blanket, a heat preservation b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com