Electromembrane coupling type dyeing waste water deep treatment and component recycling method

A printing and dyeing wastewater and advanced treatment technology, which is applied in textile industry wastewater treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of long process flow, achieve short process flow, and solve the problem of limited water supply or sewage discharge problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

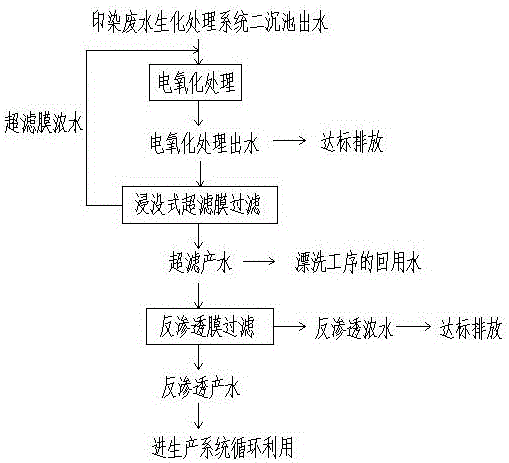

[0036] The effluent from the secondary settling tank of a biochemical treatment system in a textile printing and dyeing enterprise was used as raw water. The water quality: pH6.9, CODcr 215mg / L, chroma 120.

[0037] (1) Electro-oxidation treatment: wastewater at a current density of 11.5mA / cm 2 1. Under the condition of the tank voltage of 6.5V, after being treated by the electro-oxidation device, the water retention time is 30min, and the effluent water quality: pH is 7.17, CODcr is 76 mg / L, and the chromaticity is 30.

[0038] (2) Submerged ultrafiltration treatment: the ultrafiltration membrane is made of polyvinylidene fluoride (PVDF) hollow fiber membrane, the rated pore size is 0.01μm, the ultrafiltration pressure is 0.15-0.20MPa, the water temperature is 26-28℃, and the recovery of water The rate is 90%.

[0039] Ultrafiltration effluent quality: pH is 7.15, CODcr is 70mg / L, chroma is 20, which meets the requirements of simple reuse water and chroma for printing and dy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com