A kind of epoxy resin composition using acrylate as latent curing agent

A latent curing agent, epoxy resin technology, applied in the field of epoxy resin preparation, can solve the problems of high curing temperature, crystallization, short storage period, etc., achieve high temperature reaction speed, good mechanical properties, normal temperature storage period long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

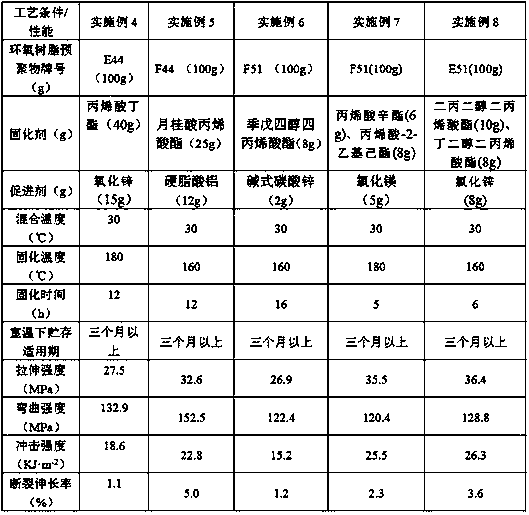

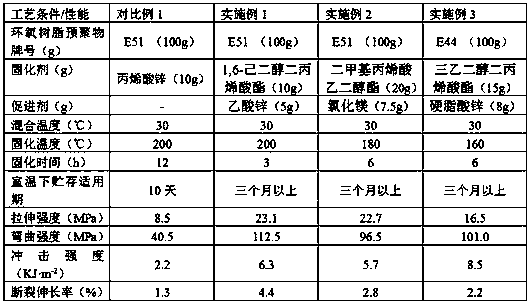

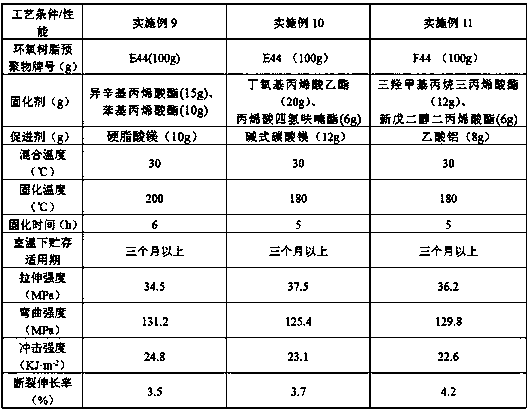

Examples

Embodiment 1

[0016] Add 10g of 1,6-hexanediol diacrylate and 5g of zinc acetate to 100g of E51 bisphenol A epoxy resin in turn, mix well at 30°C; then pour the mixture into the mold and remove it in a vacuum oven at 60°C Foaming until the degassing is complete; raise the temperature of the oven to 200°C, and cure under vacuum for 3 hours. After the curing is complete, the epoxy resin cured product with acrylate as the latent curing agent is demoulded.

Embodiment 2

[0018] Add 20g of ethylene glycol dimethacrylate and 7.5g of magnesium chloride to 100g of E51 bisphenol A epoxy resin in turn, mix well at 30°C; then pour the mixture into the mold, and defoam in a vacuum oven at 60°C, Until the defoaming is complete; raise the temperature of the oven to 180° C., and cure under vacuum for 6 hours. After the curing is complete, the epoxy resin cured product with acrylate as the latent curing agent is demolded.

Embodiment 3

[0020] Add 15g of triethylene glycol diacrylate and 8g of zinc stearate to 100g of E44 bisphenol A epoxy resin in turn, mix well at 30°C; then pour the mixture into the mold, and defoam in a vacuum oven at 60°C , until the defoaming is complete; raise the temperature of the oven to 160° C., and cure under vacuum for 6 hours. After the curing is complete, the epoxy resin cured product with acrylate as the latent curing agent is demoulded.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com