Modified plastic shell for capacitor

A plastic shell and capacitor technology, which is applied in the field of capacitors, can solve the problems of physical and mechanical performance degradation, poor impact resistance, poor light and thermal stability, etc., and achieve improved organizational structure, good weather resistance, and good compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A modified plastic casing for capacitors, which is made of the following components in parts by weight: polybutylene terephthalate 70, ABS plastic 35, filler 8, color masterbatch 1, dimethyl trimethylsilyl phosphonate Ester 4, polyvinyl chloride resin 12, lubricant 3, modifier 0.5; the modifier is made of the following ingredients in parts by weight: carboxycellulose 3, sorbitol trioleate 2, rosin 8, six Sodium Metaphosphate 1, Alkali Lignin 2, Acrylamide 2, Diatomaceous Earth 1, Sodium Tripolyphosphate 1, Methyl Salicylate 1, Tea Seed Oil 4, Peppermint Oil 0.1.

Embodiment 2

[0018] A modified plastic casing for capacitors, which is made of the following components in parts by weight: polybutylene terephthalate 90, ABS plastic 45, filler 12, color masterbatch 3, dimethyl trimethylsilyl phosphonate Ester 7, polyvinyl chloride resin 15, lubricant 6, modifier 0.8; the modifier is made of the following components in parts by weight: carboxycellulose 5, sorbitol trioleate 6, rosin 10, six Sodium metaphosphate 3, alkali lignin 4, acrylamide 4, diatomaceous earth 4, sodium tripolyphosphate 3, methyl salicylate 4, tea seed oil 6, peppermint oil 0.3.

Embodiment 3

[0020] A modified plastic casing for capacitors, which is made of the following components in parts by weight: polybutylene terephthalate 80, ABS plastic 40, filler 9, color masterbatch 2, dimethyl trimethylsilyl phosphonate Ester 6, polyvinyl chloride resin 14, lubricant 5, modifying agent 0.7; the modifying agent is made of the following components in parts by weight: carboxycellulose 4, sorbitol trioleate 3, rosin 9, six Sodium metaphosphate 2, alkali lignin 3, acrylamide 3, diatomaceous earth 2, sodium tripolyphosphate 2, methyl salicylate 2, tea seed oil 5, peppermint oil 0.2.

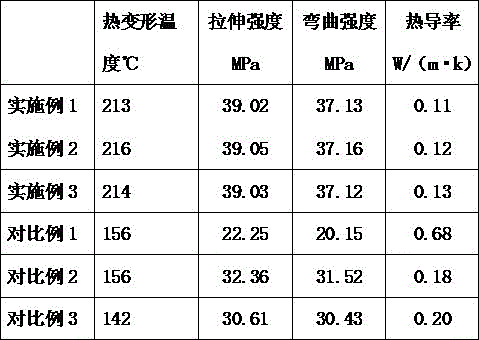

[0021] Through experiments to compare the performance of capacitor plastic casings:

[0022] Table 1

[0023]

[0024] Wherein, comparative example 1 is: without adding modifying agent in embodiment 2 of the present invention, other components remain unchanged;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com