High-yield preparation method for active polysaccharides of wheat bran

A technology for wheat bran and active polysaccharide, which is applied in the field of plant polysaccharide extraction, can solve the problems of affecting the biological activity of wheat bran polysaccharide and destroying the polysaccharide structure, and achieves the effects of mild extraction conditions, good activity and simple extraction operation steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

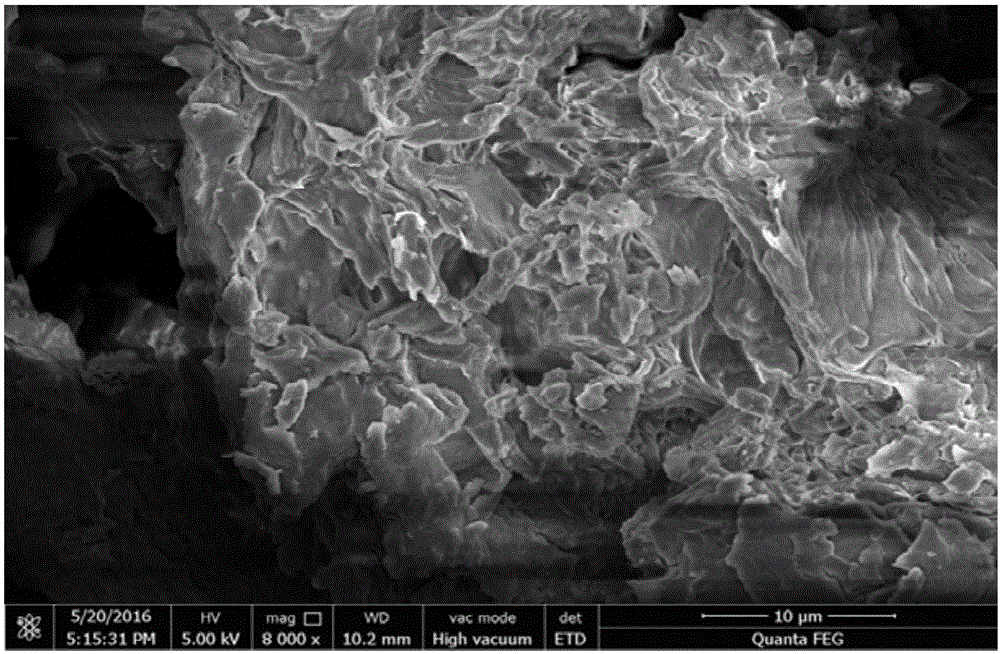

[0040] (1) Wheat bran pretreatment: After the wheat bran is mechanically crushed, impurities are removed, and the removed wheat bran is heated and dried in an oven at 30°C until the moisture content of the wheat bran is within 3%. Then, the wheat bran is further pulverized by an ultrafine pulverizer until the particle size is 500 mesh, and the wheat bran ultrafine powder is obtained;

[0041] (2) Degreasing treatment of wheat bran: according to the ratio of 1:6 of the mass grams of wheat bran superfine powder and the volume milliliter of sherwood oil, sherwood oil is added in wheat bran superfine powder; The obtained mixed system was stirred in a water bath at 30°C for 4 hours, degreased, and then the defatted wheat bran superfine powder was dried in an oven at 40°C;

[0042](3) Wheat bran crude polysaccharide extraction: take by weighing wheat bran superfine powder after degreasing, and by the mass gram ratio of the wheat bran superfine powder after degreasing and water is th...

experiment example 1 Embodiment 1

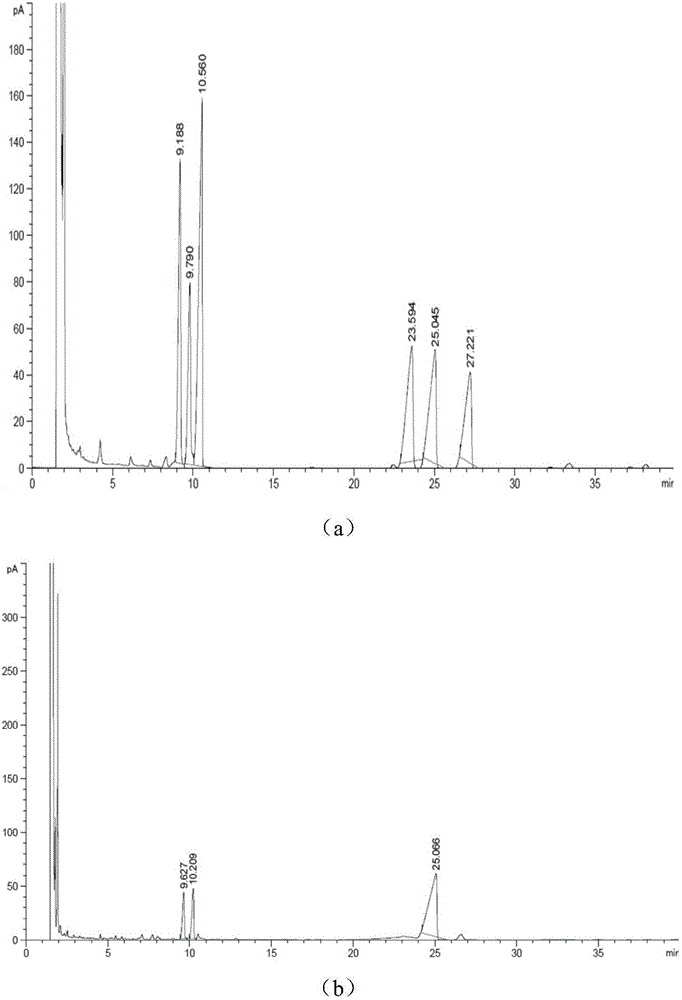

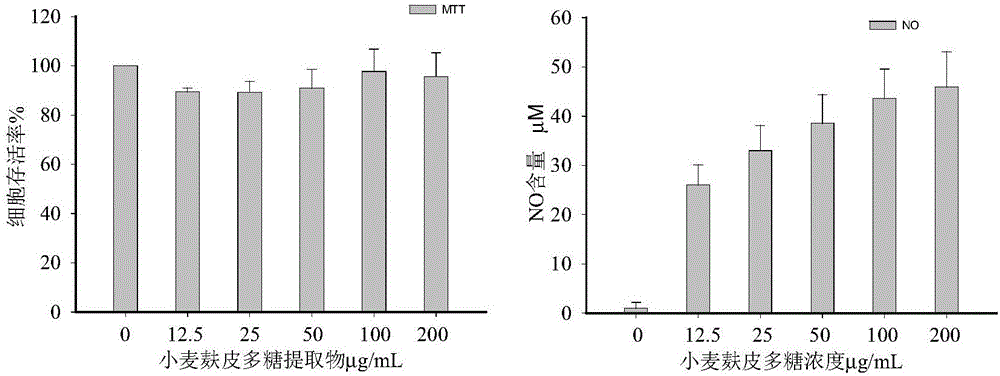

[0045] Experimental example 1 Example 1 Wheat bran crude polysaccharide and wheat bran active polysaccharide sample test

[0046] 1) Determination of polysaccharide content in wheat bran crude polysaccharide according to phenol-sulfuric acid method:

[0047] (1) Drawing of the standard curve: Accurately weigh 10 mg of glucose dried at 105°C to constant weight, and dilute to a 100 mL volumetric flask with distilled water to obtain a standard solution; dilute the standard solution to a mass concentration of 50, 100, 150, 200, 250 , 300, and 350 mg / mL solutions, absorb 0.2 mL of the diluent, add 0.4 mL of 5% phenol by mass fraction, and quickly add 2 mL of concentrated sulfuric acid after mixing. Make a blank control; make a standard curve with the polysaccharide concentration as the abscissa (X) and the absorbance as the ordinate (Y);

[0048] (2) Sample determination: take by weighing 40-50 mg of the wheat bran crude polysaccharide sample extracted in Example 1, distilled wate...

Embodiment 2

[0062] (1) Wheat bran pretreatment: After the wheat bran is mechanically crushed, impurities are removed, and the removed wheat bran is heated and dried in a 60°C oven until the moisture content of the wheat bran is within 6%. Then, the wheat bran is further pulverized by an ultrafine pulverizer until the particle size is 2000 mesh sieves to obtain wheat bran ultrafine powder;

[0063] (2) Degreasing treatment of wheat bran: according to the ratio of 1:4 of the mass grams of wheat bran superfine powder and the volume milliliter of sherwood oil, sherwood oil is added in wheat bran superfine powder; Then, will The resulting mixed system was stirred for 4 hours in a water bath at 30°C for degreasing, and then the degreased superfine wheat bran powder was dried in an oven at 40°C;

[0064] (3) Wheat bran crude polysaccharide extraction: take by weighing wheat bran superfine powder after degreasing, and by the mass gram ratio of the wheat bran superfine powder after degreasing and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com