Process for extracting chondroitin sulfate from pigs

An extraction process, the technology of chondroitin, applied in the field of extraction process of porcine chondroitin sulfate, can solve the problems of affecting biological activity, long production cycle, unstable quality, etc., and achieve the effects of reduced dosage, short production cycle and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

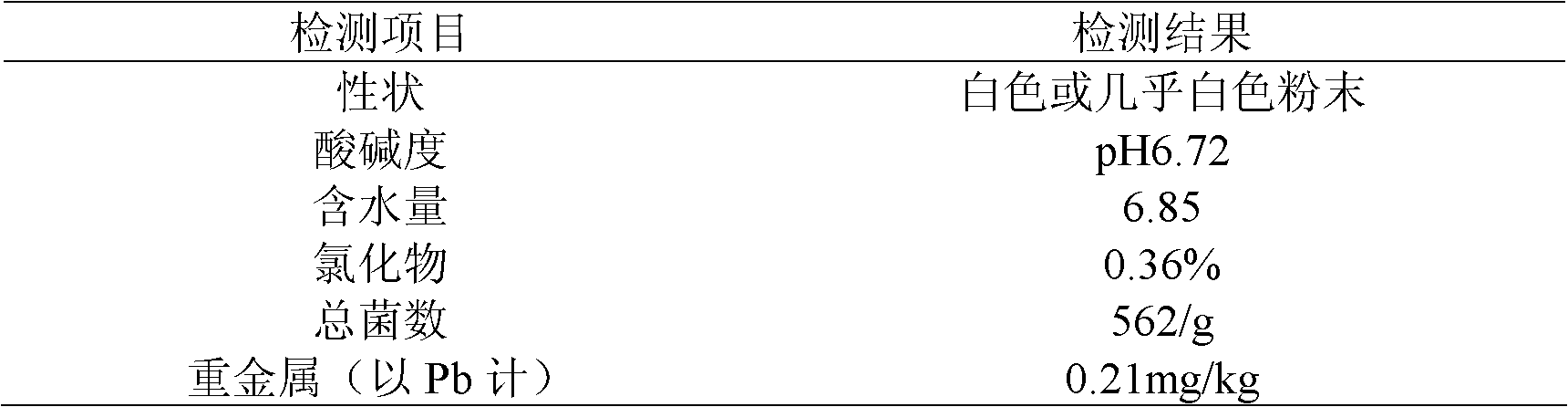

Embodiment 1

[0028] (1) Pretreatment: remove the fat and meat residue from the fresh pork nose bone, and cut it into small pieces with a length of 2.0 cm;

[0029] (2) Enzymolysis: 5.0 kg of pig nose bone with a moisture content of 82% is put into the reactor, and 20.0 L of distilled water is added, and 0.04 kg of trypsin and alkaline endoprotease are added in a mass ratio of 1: 1. For the complex protease, adjust the pH value to 8.5 with 3.0 mol / L sodium hydroxide solution, control the temperature at 55°C, and mechanically stir for 6 hours to obtain the enzymatic hydrolysis solution;

[0030] (3) Adsorption decolorization: filter the enzymatic solution in step (3) to obtain 22.6 L of filtrate, and adjust the pH value to 6.0 with 4.0 mol / L hydrochloric acid, add 0.11 kg of kaolin and 0.68 kg of activated carbon to stir and adsorb for 1 hour, temperature control At 50°C, filter while hot to obtain 22.0L of adsorption filtrate;

[0031] (4) Protein salting out: adjust the pH value of 22.0L ...

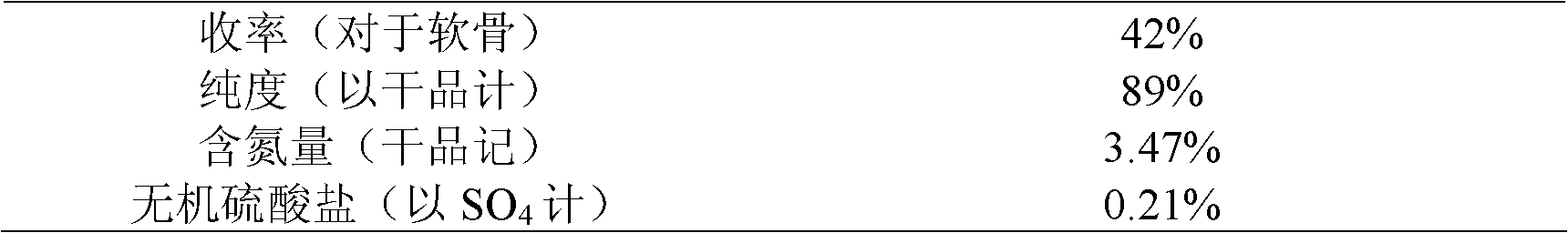

Embodiment 2

[0035] (1) Pretreatment: remove the grease and meat residue from the fresh pig throat and trachea, and cut them into small pieces with a length of 3.0 cm;

[0036] (2) Enzymolysis: Put 8.0 kg of pig laryngeal bone and trachea fragments with a moisture content of 79% into the reactor, add 40.0 L of distilled water, and add 0.08 kg of microbial alkaline protease and alkaline endolytic The protease is compounded at a mass ratio of 1:3, the pH value is adjusted to 8.0 with 1.0 mol / L potassium hydroxide solution, the temperature is controlled at 58° C., and mechanically stirred for 8 hours to obtain an enzymolyzed solution;

[0037] (3) Adsorption and decolorization: Centrifuge the enzymolysis solution in step (2) to remove slag, obtain 45.0 L of supernatant, and adjust the pH value to 4.0 with 6.0 mol / L hydrochloric acid, add 0.68 kg of kaolin and 0.90 kg of activated carbon to stir and adsorb 1.5 hour, the temperature was controlled at 47°C, and 44.5L of adsorption filtrate was o...

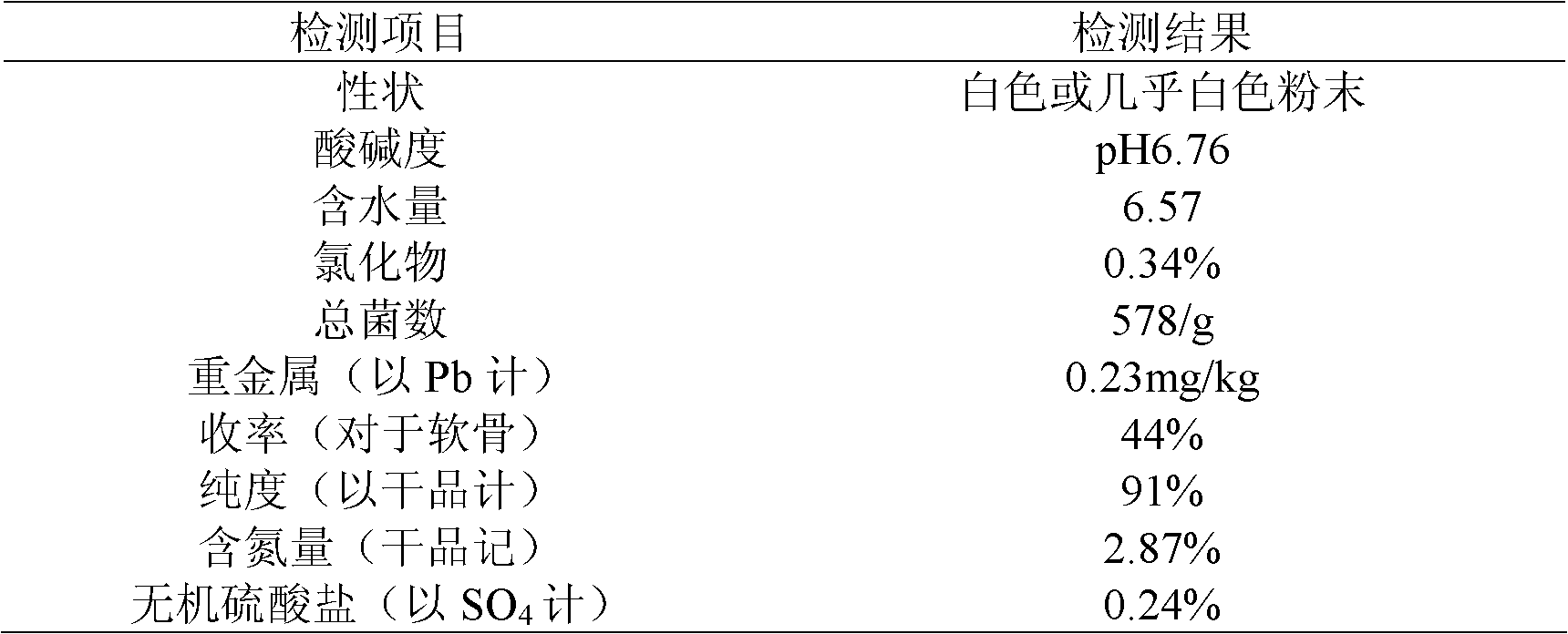

Embodiment 3

[0042] (1) Pretreatment: remove the fat and meat residue from the fresh pig soft ribs and crescent bones, and cut them into small pieces with a length of 1.5cm;

[0043] (2) Enzymolysis: Put 10.0 kg of pig soft rib and crescent bone with a moisture content of 75% into the reactor, add 30.0 L of distilled water, add 0.09 kg of trypsin and microbial alkaline protease in a mass ratio of 1 : 3 complex compound proteases, the pH value is adjusted to 8.7 with 2.0mol / L potassium hydroxide solution, the temperature is controlled at 60°C, and mechanically stirred for 12 hours to obtain the enzymolysis solution;

[0044] (3) Adsorption decolorization: filter the enzymolysis solution in step (2) to obtain 35.8 L of filtrate, adjust the pH value to 5.0 with 2.0 mol / L sulfuric acid, add 0.72 kg of kaolin and 0.54 kg of activated carbon to stir and adsorb for 2 hours, temperature control At 45°C, filter while hot to obtain 35.2L of adsorption filtrate;

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com