Continuous washing device and method for electrolytic copper powder

A technology of electrolytic copper powder and cleaning device, which is applied in the field of electrolysis, can solve problems such as the complexity of the cleaning process, and achieve the effects of simplifying the process, reducing losses, and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

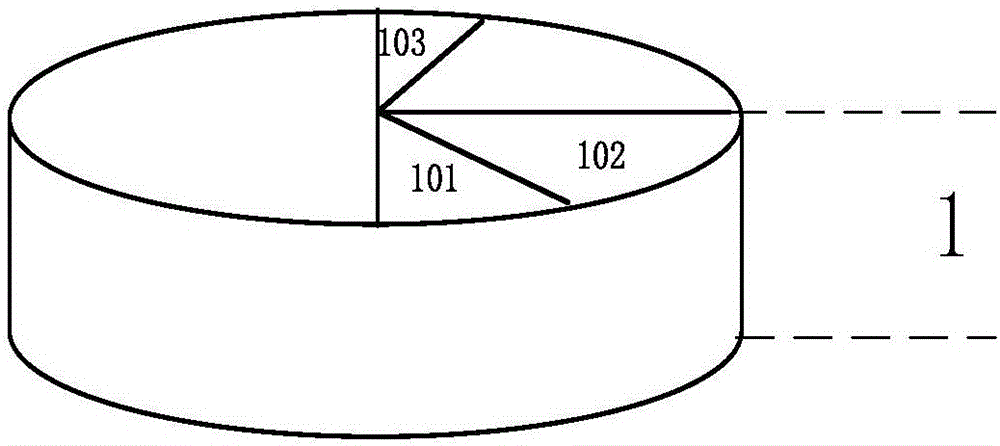

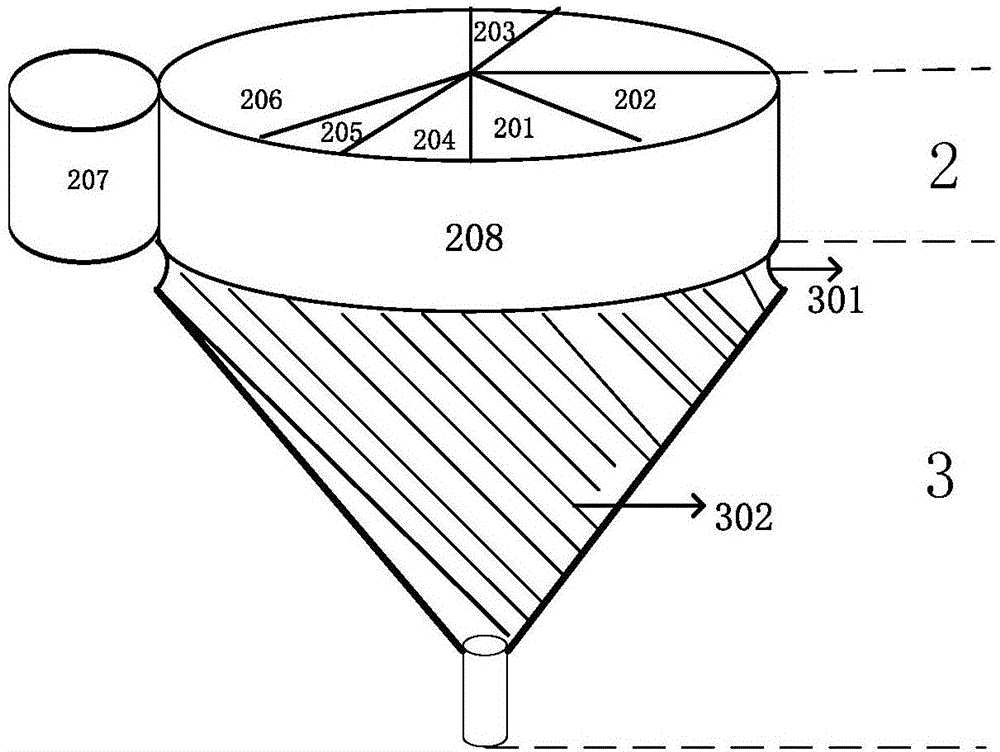

Image

Examples

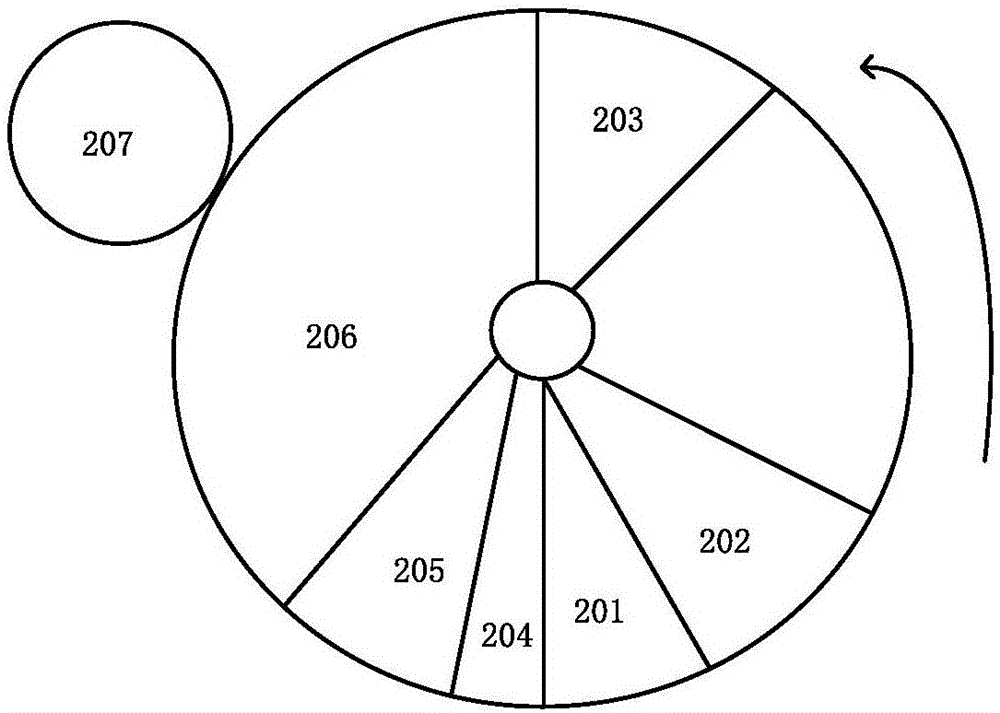

Embodiment 1

[0028] Ordinary electrolytic copper powder is divided into two batches. One ton of powder product is processed by the original process, washed 7 times in the powder washing machine, washed three times after saponification, dried by centrifugal dryer for 30 minutes, and then enters the reduction furnace for reduction and drying, and then passes through the crusher. After crushing and classification by air classifier, the bulk density of sieved -200 mesh copper powder is 1.78g / cm 3 , the oxygen content is 565ppm, the water content is 0.04%, a total of 7 tons of water is used, and the labor time is 10 hours; the other ton is cleaned in the continuous cleaning electrolytic copper powder device, the speed of the turntable is 4 minutes / week, and the vacuum degree of suction filtration is 0.2M Pa , Surface anti-oxidation treatment with 0.5% unsaturated fatty acid. Then enter the reduction furnace for reduction and drying. After the copper powder material is discharged, it is screened...

Embodiment 2

[0030] Electrolytic copper powder with low loose ratio is divided into two batches, one ton is processed by the original process, washed 10 times in the powder washing machine, washed three times after passivation treatment, dried by centrifugal dryer for 40 minutes, dried by hot air stove, and then passed through air flow After grading by the classifier, the bulk density of the sieved -200 mesh copper powder is 1.18g / cm 3 , the oxygen content is 1165ppm, the water content is 0.07%, a total of 9 tons of water, 15 hours of labor time; another ton of continuous cleaning electrolytic copper powder is cleaned, the speed of the turntable is 6.5 minutes / week, and the vacuum degree of suction filtration is 0.2M Pa. Then use 0.3% rust remover to passivate the surface, and then pass hot air at 210°C to fluidize the powder for drying. After the copper powder material is discharged, it is screened to obtain a -200 mesh product, and its bulk density is 0.86 g / cm 3 , oxygen content 823ppm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com