Preparation method for synthesizing recyclable CdS/CoFe2O4/rGO (reduced graphene oxide) composite photocatalyst by hydrothermal process and application of composite photocatalyst

A technology of cofe2o4 and recombination of light, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of reducing the recombination rate of electron-hole pairs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Preparation of GO:

[0030] GO was synthesized from natural graphite powder according to the Hummer method. 1g graphite powder, 2.5g NaNO 3 and 30ml of concentrated sulfuric acid were added into a 250ml three-necked flask, and the three-necked flask was placed into an ice bath for magnetic stirring. After stirring until completely dissolved, slowly add 0.4 g KMnO to the suspension 4 , stirring was continued for 2 h until the mixture turned green, at which point the mixture was cooled to 0 °C. Subsequently, it was removed from the ice bath, and reacted at 35° C. for 30 minutes, then added 40 ml of deionized water to the mixture, and reacted at 98° C. for 40 minutes. When the solution turns dark brown, add 10ml of 30% H 2 o 2 , 40ml deionized water to terminate the reaction. Finally, the product was washed 3 to 4 times with 30% HCl, precipitated, centrifuged, and dried in vacuum at 50° C. for 10 h.

[0031] (2)CoFe 2 o 4 Preparation of:

[0032] 0.0646g Fe(NO ...

Embodiment 2

[0037] By the steps in Example 1, the difference is (3) 0.1833g CdCl 2 2.5H 2 O and 0.1756g L-cysteine were dissolved in 40mL deionized water and stirred until completely dissolved; then 0.1mol L -1 Sodium hydroxide solution to adjust the pH of the above solution = 5, and then add 0.05g GO and 0.05g CoFe 2 o 4 Continue stirring evenly, then add 0.045g Na 2 S·9H 2 O and stirred evenly, then, the solution was transferred to a 180°C reaction kettle for 2h constant temperature thermal reaction; after the reaction, the precipitate was separated from the solution with a magnet, the precipitate was washed with ethanol, and dried in a vacuum oven. Get CdS / CoFe 2 o 4 / rGO composite photocatalyst.

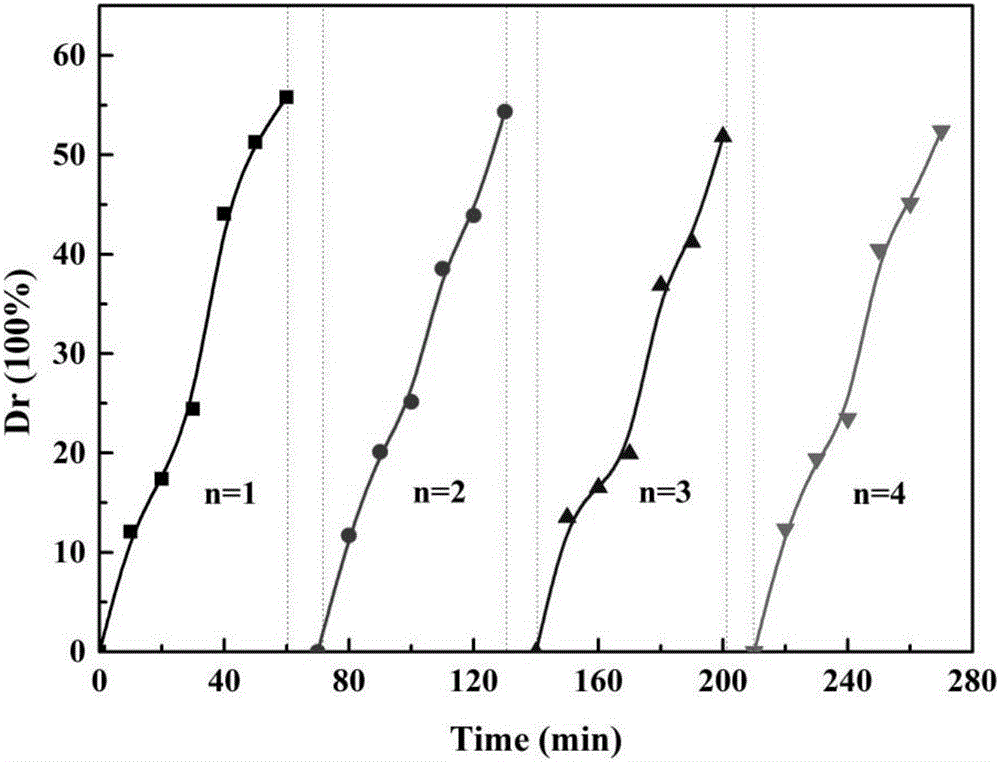

[0038] Take the sample in (3) and carry out the photocatalytic degradation test in the photochemical reaction instrument, and it is measured that the degradation rate of the photocatalyst to the ciprofloxacin antibiotic reaches 40.56% within 90 minutes.

Embodiment 3

[0040] By the steps in Example 1, the difference is (3) 0.1833g CdCl 2 2.5H 2 O and 0.1756g L-cysteine were dissolved in 40mL deionized water and stirred until completely dissolved; then 0.1mol L -1 Sodium hydroxide solution to adjust the pH of the above solution = 6, and then add 0.05g GO and 0.05g CoFe 2 o 4 Continue stirring evenly, then add 0.045g Na 2 S·9H 2 O and stirred evenly, then, the solution was transferred to a 180°C reaction kettle for 2h constant temperature thermal reaction; after the reaction, the precipitate was separated from the solution with a magnet, the precipitate was washed with ethanol, and dried in a vacuum oven. Get CdS / CoFe 2 o 4 / rGO composite photocatalyst.

[0041] The sample in (3) was taken to carry out the photocatalytic degradation test in the photochemical reaction apparatus, and it was measured that the degradation rate of the photocatalyst to the ciprofloxacin antibiotic reached 54.26% within 90 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com