High-strength plastic alloy explosion-proof oil drum

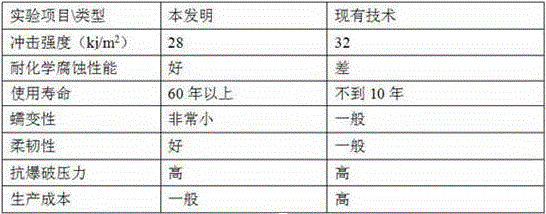

A technology of high-strength plastics and oil drums, which is applied in the packaging of hazardous substances, containers, and types of packaging items, etc., can solve the problems of easy damage, inability to bear weight, low alkali corrosion ability, etc., and achieve the effect of convenient use and good strength support.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

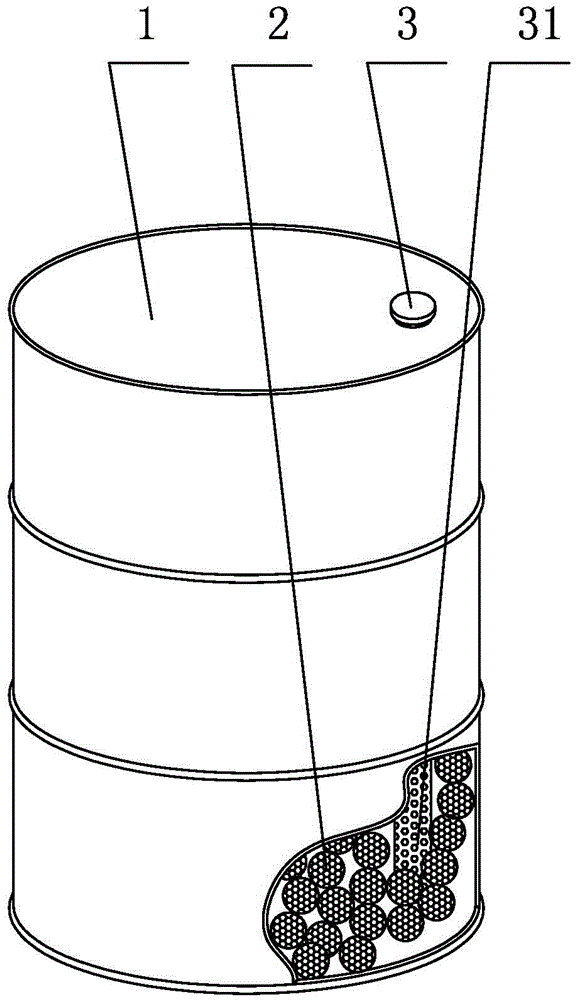

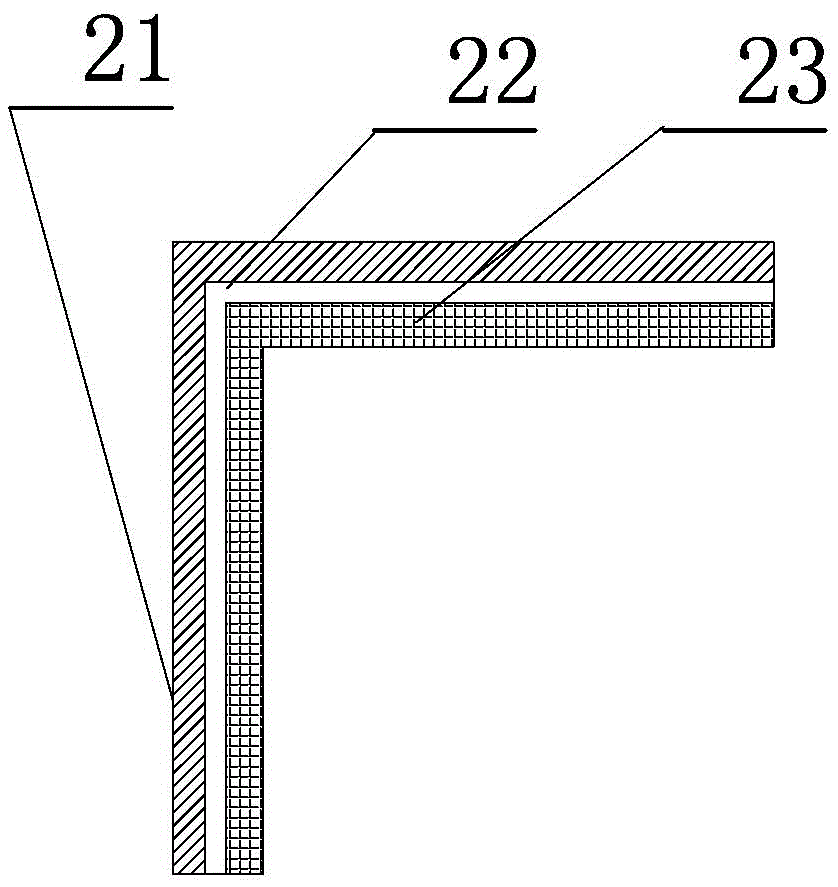

[0011] Embodiment 1: as figure 1 , 2 As shown, a high-strength plastic alloy explosion-proof oil barrel includes a container barrel body 1, and a barrel cover 3 with a breathing nozzle 31 is arranged on the top of the container barrel. It is characterized in that the container barrel body is composed of an inner liner, a middle Composed of bonding layer and HDPE weather-resistant layer, the oil drum is filled with aluminum-magnesium alloy explosion-proof material 2.

[0012] Inner liner 23 components: Add the following components by weight ratio: 100 parts of UHMWPE resin, 1 part of nano-silica, 5 parts of calcium sulfate whiskers, 5 parts of 5A molecular sieve, and 3 parts of papaya powder are added to the first screw extruder machine.

[0013] 22 components of the middle bonding layer: the following components by weight ratio: 50 parts of HDPE resin (high density polyethylene), 2 parts of 3A molecular sieve, 0.2 parts of β crystal nucleating agent (TMB-5), ethylene-α-octyl...

Embodiment 2

[0016] Embodiment 2: The inner lining layer 23 is made of the following components by weight ratio: 100 parts of UHMWPE resin, 2 parts of nano-silicon dioxide, 7 parts of calcium sulfate whiskers, 7 parts of 5A molecular sieve, and 5 parts of palygorskite powder.

[0017] The middle bonding layer 22 is made of the following components by weight ratio: 50 parts of HDPE resin (high-density polyethylene), 3 parts of 3A molecular sieve, 1.1 parts of β crystal nucleating agent (TMB-5), ethylene-α-octene 8 parts of copolymer.

[0018] The HDPE weather-resistant layer 21 is mainly made of the following components by weight ratio: 85 parts of HDPE resin, 6 parts of nano-silicon dioxide, 6 parts of calcium sulfate whiskers, 5 parts of 5A molecular sieve, 5 parts of calcium stearate, and 3 parts of nano-sized titanium dioxide. 0.5 parts of tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, 0.5 parts of phenyl o-hydroxybenzoate, and 0.3 parts of polyethylen...

Embodiment 3

[0019] Embodiment 3: The inner lining layer 23 is made of the following components by weight ratio: 100 parts of UHMWPE resin, 2 parts of nano-silicon dioxide, 5 parts of calcium sulfate whiskers, 6 parts of 5A molecular sieve, and 4 parts of papaya powder.

[0020] The middle bonding layer 22 is made of the following components by weight ratio: 50 parts of HDPE resin (high-density polyethylene), 3 parts of 3A molecular sieve, 0.8 part of β crystal nucleating agent (TMB-5), ethylene-α-octene 7 parts of copolymer.

[0021] The HDPE weather-resistant layer 21 is mainly made of the following components by weight: 83 parts of HDPE resin, 4 parts of nano-silicon dioxide, 4 parts of calcium sulfate whiskers, 4 parts of 5A molecular sieve, 3 parts of calcium stearate, and 3 parts of nano-sized titanium dioxide. 0.4 parts of tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, 0.4 parts of phenyl o-hydroxybenzoate, and 0.3 parts of polyethylene wax. The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com