A kind of fluorine-modified titanium aluminum phosphate molecular sieve f-tapo-5 and preparation method thereof

A technology of F-TAPO-5, titanium aluminum phosphate, applied in the direction of molecular sieve characteristic aluminum phosphate, molecular sieve catalyst, molecular sieve and alkali exchange phosphate, etc., to achieve the effect of easy process, low price and less time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

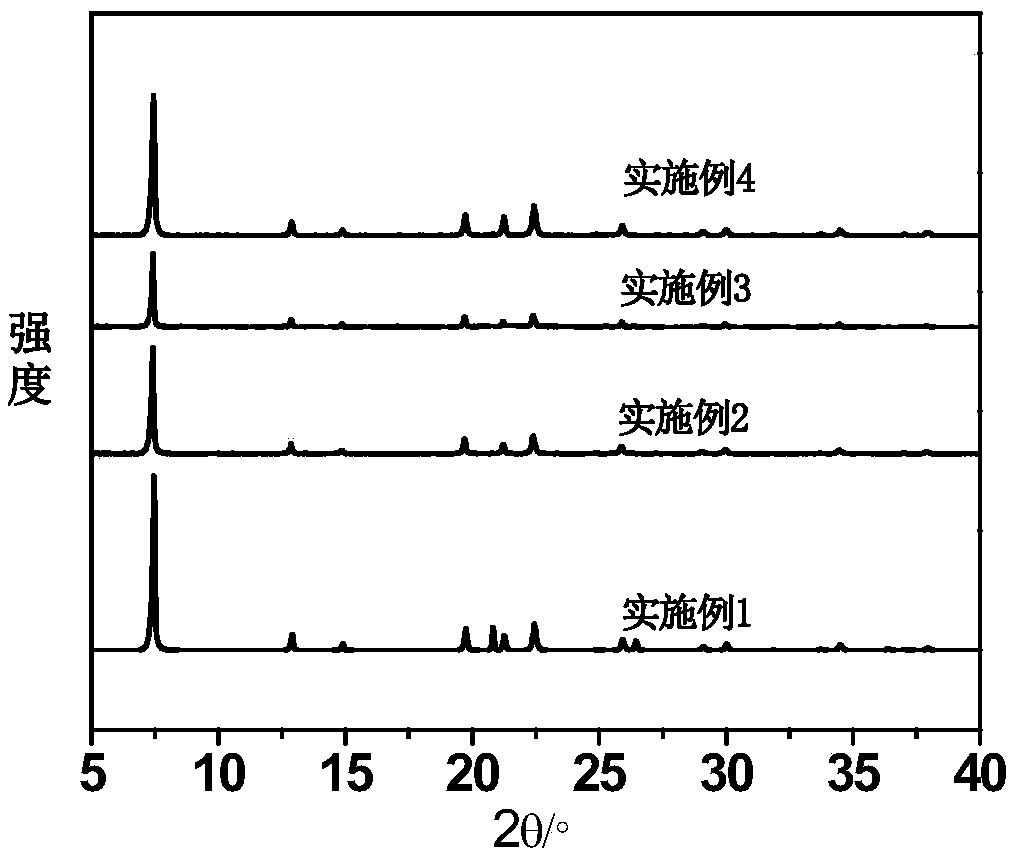

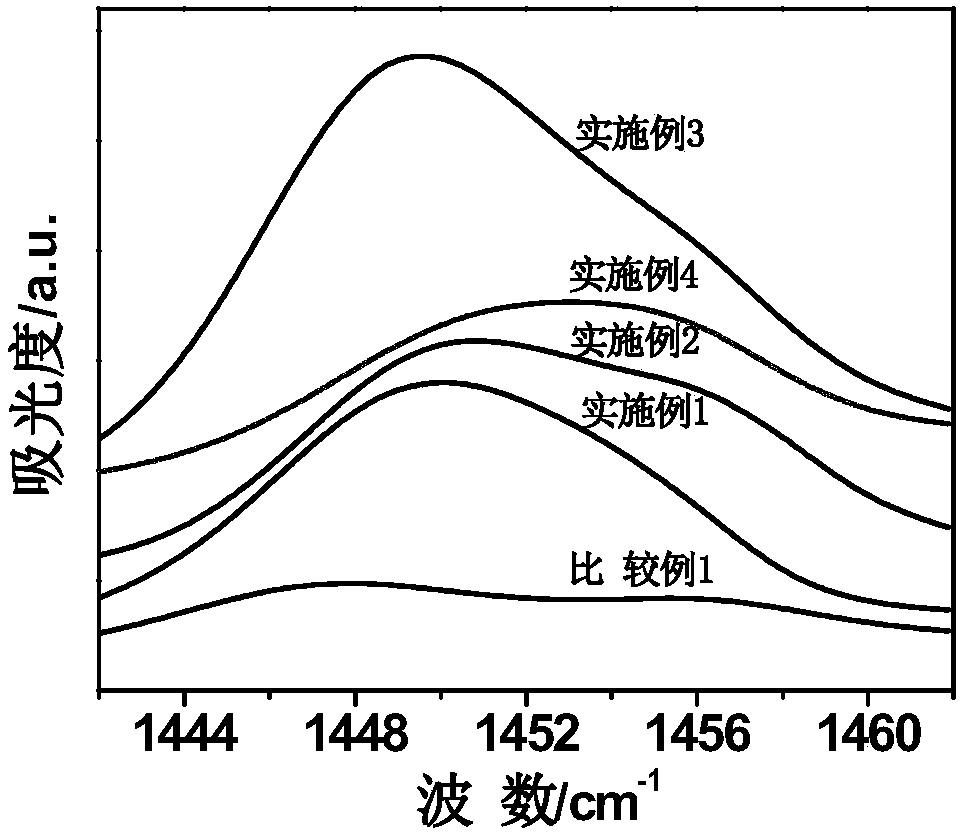

Embodiment 1

[0039] 4.151g H 3 PO 4 and 10.0 g H 2 O was stirred and mixed at 30°C, and 2.7648g Al(OH) was weighed 3 The powder was added to the above system, and after stirring for 0.5h, 0.191g N 2 h 8 TiF 6 Powder is added to the system. Then 3.751g MCHA is slowly added dropwise in the above-mentioned suspension, finally add 10.0g water, the molar ratio of raw materials is Al(OH) 3 :H 3 PO 4 :N 2 h 8 TiF 6 :MCHA:H 2 O=0.96:1.5:0.04:0.8:50, continue to stir vigorously for 1 hour, then transfer it to a stainless steel crystallization kettle lined with polytetrafluoroethylene, and crystallize at 180°C for 24 hours. After the crystallization is completed, centrifuge and wash with distilled water until neutral, and dry at 110°C for 12 hours to obtain the original powder of F-TAPO-5. The obtained F-TAPO-5 raw powder was calcined in a tube furnace at 575° C. for 6 hours in an oxygen atmosphere to remove the structure-directing agent and obtain a molecular sieve, labeled as: F-TAPO-...

Embodiment 2

[0041]4.151g H 3 PO 4 and 10.0 g H 2 O was stirred and mixed at 30°C, and 2.7648g Al(OH) was weighed 3 The powder was added to the above system, and after stirring for 0.5h, 0.764g N 2 h 8 TiF 6 Powder is added to the system. Then 3.751g MCHA is slowly added dropwise in the above-mentioned suspension, finally add 10.0g water, the molar ratio of raw materials is Al(OH) 3 :H 3 PO 4 :N 2 h 8 TiF 6 :MCHA:H 2 O=0.96:1.5:0.1:0.8:50, continue to stir vigorously for 1 hour, then transfer it to a stainless steel crystallization kettle lined with polytetrafluoroethylene, and crystallize at 180°C for 24 hours. After the crystallization is completed, centrifuge and wash with distilled water until neutral, and dry at 110°C for 12 hours to obtain the original powder of F-TAPO-5. The obtained F-TAPO-5 raw powder was calcined in a tube furnace at 575° C. for 6 hours in an oxygen atmosphere to remove the structure-directing agent and obtain a molecular sieve, labeled as: F-TAPO-5 ...

Embodiment 3

[0043] 4.151g H 3 PO 4 and 10.0 g H 2 O was stirred and mixed at 30°C, and 2.7648g Al(OH) was weighed 3 The powder was added to the above system, and after stirring for 0.5h, 1.528g N 2 h 8 TiF 6 Powder is added to the system. Then 3.751g MCHA is slowly added dropwise in the above-mentioned suspension, finally add 10.0g water, the molar ratio of raw materials is Al(OH) 3 :H 3 PO 4 :N 2 h 8 TiF 6 :MCHA:H 2 O=0.96:1.5:0.2:0.8:50, continue to stir vigorously for 1 hour, then transfer it to a stainless steel crystallization kettle lined with polytetrafluoroethylene, and crystallize at 180°C for 24 hours. After the crystallization is completed, centrifuge and wash with distilled water until neutral, and dry at 110°C for 12 hours to obtain the original powder of F-TAPO-5. The obtained F-TAPO-5 raw powder was calcined in an air atmosphere at 575° C. for 6 hours to remove the structure directing agent in a muffle furnace to obtain a molecular sieve, labeled as: F-TAPO-5 (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com