Method for starting nitration reaction in microaerobic condition

A technology of nitrification reaction and conditions, applied in chemical instruments and methods, aerobic and anaerobic process treatment, water treatment parameter control, etc., can solve the problem of long generation time of nitrifying bacteria, high technical requirements for aeration devices, and large aeration volume To achieve the effect of saving energy consumption, improving the stability of working performance and reducing the amount of aeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

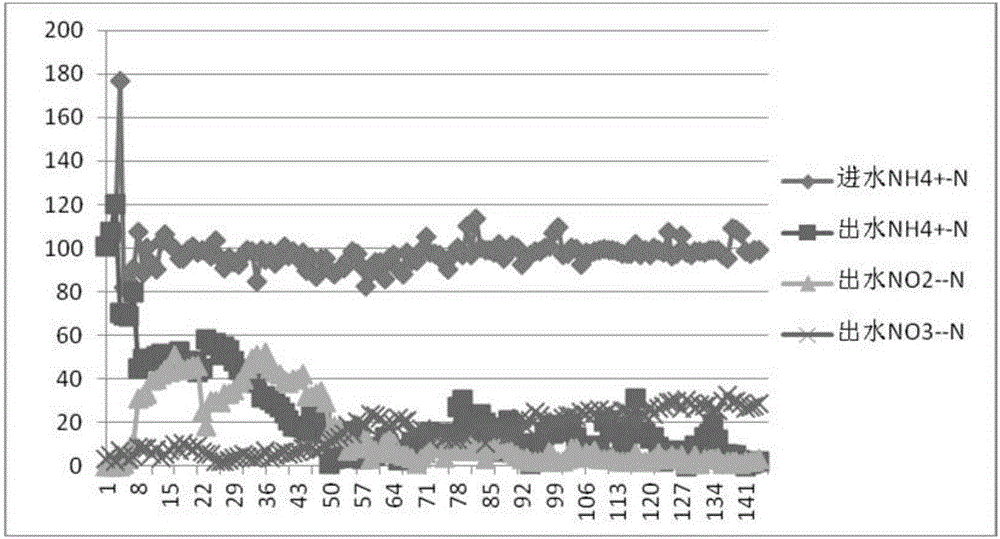

[0026] The water quality parameters of a wastewater containing ammonia nitrogen are as follows: pH 7.8-8.3, COD cr 0-10mg / L, NH 4 + -N 80-120mg / L, NO 2 - -N 0.0mg / L, NO 3 - -N 2.0-2.3 mg / L.

[0027] Process flow of the present invention is:

[0028] (1) Seed mud preparation. Ordinary activated sludge from the secondary sedimentation tank of urban sewage treatment plant is used as the seed sludge, the color is light yellowish brown, the pH is in the range of 7.0-7.2, and the MLSS is in the range of 3000-4000mg / L. After 12 hours of precipitation, MLSS is in the range of 14000-14500mg / L, and MLVSS is in the range of 8000-8500mg / L;

[0029] (2) Inoculate seed mud. After the seed sludge in step (1) is aerated with air for 72 hours, the sludge concentration is adjusted within the range of 14000-14500 mg / L. Get 2.5L of this sludge and pour it into the SBAF reactor with combined filler suspended and an effective volume of 3L;

[0030] (3) Biological hanging film. The bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com