Slag light particle-coated unfired ceramsite and preparation method thereof

A technology of slag and granules, which is applied in the field of slag light particle-coated non-fired ceramsite and its preparation, can solve the problems of carbon emission, large consumption of land resources and mineral resources, etc., and achieve saving of construction investment, good seismic performance and good market Effects of space and prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

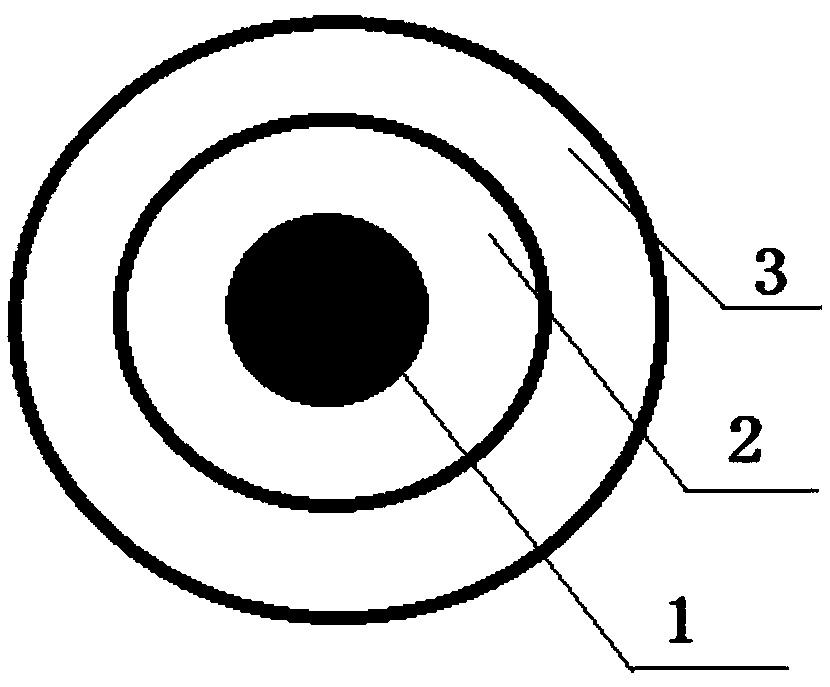

[0033] like figure 1 As shown, a kind of slag light particle-coated shell unfired ceramsite, it includes slag light particle pottery core 1, shell powder layer 2 wrapped on the outer periphery of pottery core 1 and reinforcement and Anti-carbonization fabric layer 3;

[0034] The slag light particle ceramic core 1 is slag light particle with a particle diameter of 3-15 mm.

[0035] The above-mentioned slag light particle-coated unfired ceramsite, the described shell powder layer 2 is made of the following raw materials in parts by weight: 800 parts of slag fine powder, 50 parts of activator calcium hydroxide, binder Such as water glass 100 parts.

[0036] For the slag light particle-coated unfired ceramsite above, the reinforcing and anti-carbonization fabric layer 3 is made of the following raw materials in parts by weight: 800 parts of Portland cement and 50 parts of epoxy resin.

Embodiment 2

[0038] like figure 1 As shown, a kind of slag light particle-coated shell unfired ceramsite, it includes slag light particle pottery core 1, shell powder layer 2 wrapped on the outer periphery of pottery core 1 and reinforcement and Anti-carbonization fabric layer 3;

[0039] The slag light particle ceramic core 1 is slag light particle with a particle diameter of 3-15mm.

[0040] The above-mentioned slag light particle-coated shell-free ceramsite, the shell-coated powder layer 2 is made of the following raw materials in parts by weight: 600 parts of slag fine powder, 500 parts of fly ash, 500 parts of slag powder, 100 parts of activator calcium bicarbonate, 200 parts of binder water glass.

[0041] For the slag light particle-coated unfired ceramsite above, the reinforcing and anti-carbonization fabric layer 3 is made of the following raw materials in parts by weight: 950 parts of Portland cement and 100 parts of epoxy resin.

Embodiment 3

[0043] A method for preparing unfired ceramsite coated with slag light particles, comprising the following steps:

[0044] (1) Multi-stage screening of slag: sieve light slag particles with a particle size of 3-15mm, and then subdivide them into light slag particles with particle sizes of 3-6mm, 6-10mm and 10-15mm. The particles are used as slag light particle pottery core; the rest of the slag is partially ground and processed into slag fine powder;

[0045] (2) Get the slag fine powder of step (1) and mix activator and binding agent (950 parts of slag fine powder, 100 parts of activator calcium hydroxide, 200 parts of binding agent water glass), mix, be prepared into encasement Powder;

[0046](3) Take Portland cement, add modified resin to prepare reinforcement and anti-carbonization surface layer powder (950 parts of Portland cement, 100 parts of epoxy resin);

[0047] (4) The slag light particle pottery core obtained by screening step (1) is placed in the first ball for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com