Nano composite material, preparation method thereof, rubber composition, vulcanized rubber and applications thereof

A technology of nano-composite materials and rubber compositions, applied in other chemical processes, chemical instruments and methods, dyed low-molecular organic compound treatment, etc., can solve the problems of inability to prepare high-performance rubber materials, and achieve favorable mechanical properties and The effect of processing, excellent mechanical properties, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

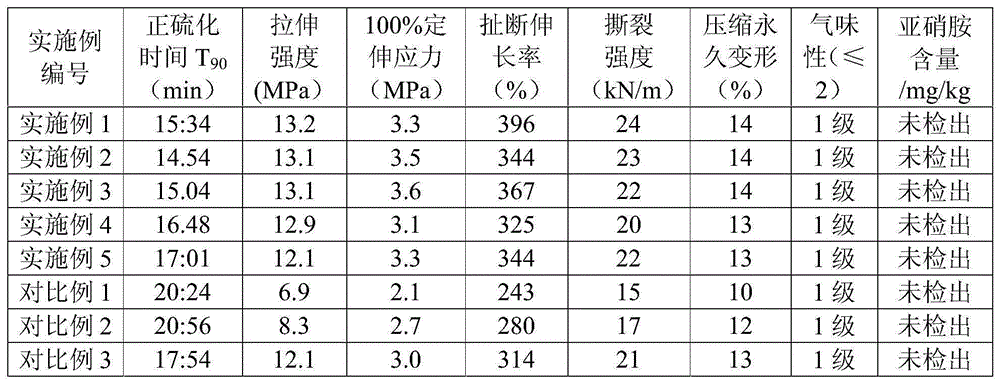

Examples

preparation example Construction

[0026] In a second aspect, the present invention provides a method for preparing a nanocomposite material, wherein the method includes: adding the above-mentioned modifying agent to the aqueous dispersion of nano calcium carbonate to modify the nano calcium carbonate sex.

[0027] According to the present invention, the consumption of described nano-calcium carbonate and modifier is not particularly limited, as long as the nano-calcium carbonate surface performance can be changed from hydrophilic to lipophilic, generally, with respect to the nano-calcium carbonate of 100 parts by weight , the amount of the modifier is 1-10 parts by weight, preferably 5-10 parts by weight.

[0028] According to the present invention, the preparation method of the aqueous dispersion of nano-calcium carbonate is not particularly limited, as long as it can form a uniform aqueous dispersion, for example, nano-calcium carbonate can be added to deionized water and mixed to prepare Aqueous dispersion...

Embodiment 1

[0066] This embodiment is used to illustrate the nanocomposite material provided by the present invention and its preparation method and vulcanized rubber

[0067] (1) 200g particle diameter is that the nano-calcium carbonate of 60nm is dropped in 2L aqueous solution, after 15min with the stirring speed mechanical stirring of 3000rpm at 25 ℃, obtain the aqueous dispersion liquid of nano-calcium carbonate.

[0068] (2) add 15g modifying agent L-cystine in the water dispersion liquid of the nano-calcium carbonate that step (1) obtains, at 80 ℃ of temperature, stir 80min under the rotating speed of 3000rpm, obtain modified nano-calcium carbonate suspension .

[0069] (3) The resulting suspension was spray-dried at a rotational speed of 16000 rpm and a spray-drying temperature of 100° C. to obtain 210 g of nanocomposite C1 with an average particle size of 450 nm.

[0070] (4) Add the following rubber composition A1 to the following rubber composition A1 at a temperature of 35±5°C...

Embodiment 2

[0082] This embodiment is used to illustrate the nanocomposite material provided by the present invention and its preparation method and vulcanized rubber

[0083] (1) 200g particle diameter is that the nano-calcium carbonate of 45nm is dropped in 2L aqueous solution, at 35 ℃ with 5000 revs / min stirring velocity machinery after 5min, obtain the aqueous dispersion liquid of nano-calcium carbonate.

[0084] (2) add 20g modifier L-methionine in the suspension that step (1) obtains, at 120 ℃ of temperature, stir 60min under the rotating speed of 5000rpm, obtain modified nanometer calcium carbonate suspension;

[0085] (3) The resulting suspension was spray-dried at a speed of 19000 rpm and a spray-drying temperature of 95° C. to obtain 215 g of nanocomposite material C2 with an average particle size of 360 nm.

[0086] (4) Add the following substances to the rubber composition A2 at a temperature of 35±5°C on a double-roller rubber mixing machine and mix them uniformly, and then m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com