Method for preparing recombinant L-glutamic acid producing strain, strain prepared by method and application method of strain

A technology for the production of strains, Corynebacterium glutamicum, applied in the field of genetic engineering, can solve the problem of low acid production performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] In the method for preparing recombinant L-glutamic acid producing strains of the present invention, the available L-glutamic acid producing strains can be, for example, wild-type Corynebacterium glutamicum, including but not limited to: Corynebacterium glutamicum wild-type Strain ATCC13032 (China Industrial Microorganism Culture Collection Management Center, preservation number CICC20213) or Corynebacterium glutamicum wild-type strain S9114 (China Industrial Microbiology Culture Collection Management Center, preservation number CICC20935).

[0034] In some embodiments of the present invention for preparing recombinant L-glutamic acid producing strains, the expression level of the target gene (such as lpdA gene and optional odhA gene and / or sucB gene) of the present invention can be obtained by the following method: Recombinant L-glutamic acid production strain: use the transformed gene sequence fragment to construct a plasmid with gene knockout or gene expression level w...

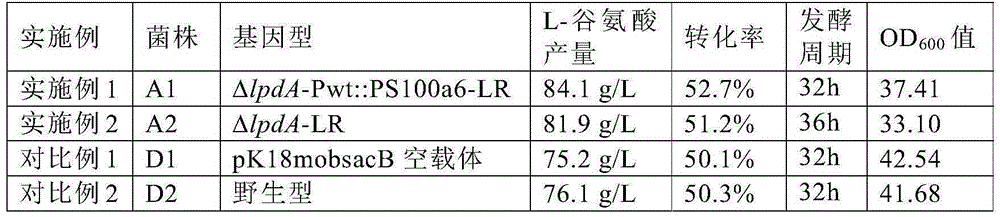

Embodiment 1

[0065] This example is used to illustrate the method for preparing the recombinant L-glutamic acid producing strain of the present invention.

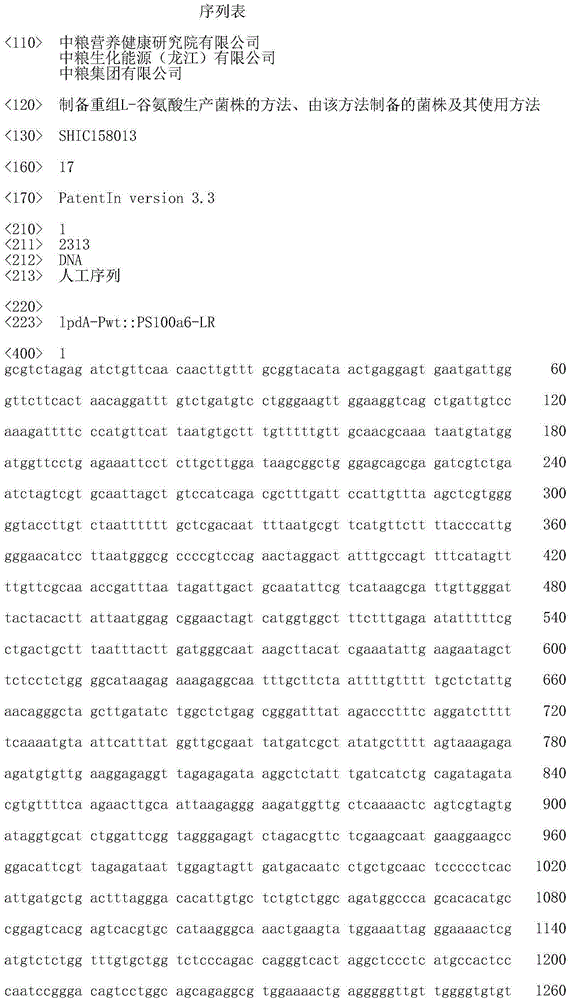

[0066] (1) Design and synthesis of ΔlpdA-Pwt::PS100a6-LR homology arm sequence:

[0067] According to the sequence of the wild-type promoter of the lpdA gene in Corynebacterium glutamicum CICC20935 and its upstream and downstream sequences, a homology arm sequence (ΔlpdA -Pwt::PS100a6-LR, as shown in SEQ ID NO: 1), and was synthesized by Beijing Qingke Xinye Biotechnology Co., Ltd.

[0068] Wherein, the sequence of the wild-type promoter of the lpdA gene in Corynebacterium glutamicum CICC20935 and its upstream and downstream sequences are respectively represented by SEQ ID NO: 12-SEQ ID NO: 14, and the sequence of the S100a6 gene promoter of Chinese hamster ovary (CHO) cells is represented by represented by SEQ ID NO: 15.

[0069] (2) Construction of pK18mobsacB-ΔlpdA-Pwt::PS100a6-LR plasmid:

[0070] The synthesized ΔlpdA-Pwt::PS10...

Embodiment 2

[0082] This example is used to illustrate the method for preparing the recombinant L-glutamic acid producing strain of the present invention.

[0083] (1) Design and synthesis of ΔlpdA-LR homology arm sequence:

[0084] According to the sequence of the lpdA gene and its upstream and downstream sequences in Corynebacterium glutamicum CICC20935, a homology arm sequence (ΔlpdA-LR) for knocking out the lpdA gene was designed: the upstream and downstream homology arms of the lpdA gene were amplified using CICC20935 genomic DNA as a template. The source arm fragments, and then the upstream and downstream homology arm fragments were connected by overlapping PCR to obtain ΔlpdA-LR (shown by SEQ ID NO: 2).

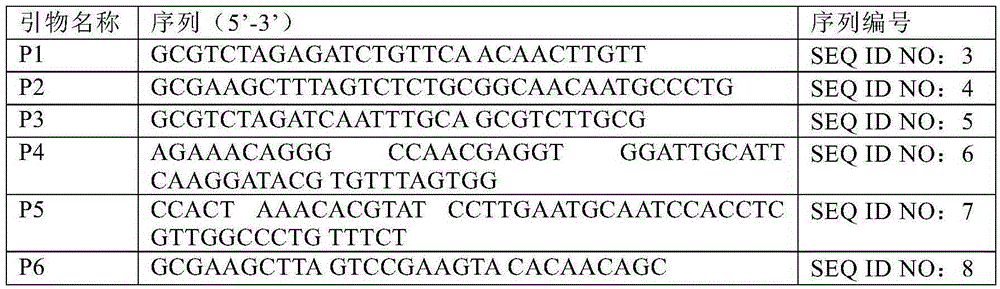

[0085] The specific steps are as follows: using the genomic DNA of Corynebacterium glutamicum CICC20935 as a template, amplify lpdA with forward primer P3 (SEQ ID NO: 5) and reverse primer P4 (SEQ ID NO: 6) as shown in Table 1 The upstream homology arm of the gene (ΔlpdA-L, 1009bp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com