Preparation method and application of cheese rich in gamma-aminobutyric acid (GABA)

A technology of aminobutyric acid and cheese, which is applied in the field of food processing, can solve the problems of difficult large-scale promotion, high cost of raw materials, and expensive products, and achieve the effects of optimizing fermentation conditions, improving vitality, and increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Embodiment 1: Determination of the optimum medium of Lactobacillus plantarum NDC75017

[0060] In this example, the effects of different carbon sources, nitrogen sources, and growth factors on the synthesis of γ-aminobutyric acid by Lactobacillus plantarum NDC75017 were studied to determine the optimal medium for Lactobacillus plantarum NDC75017.

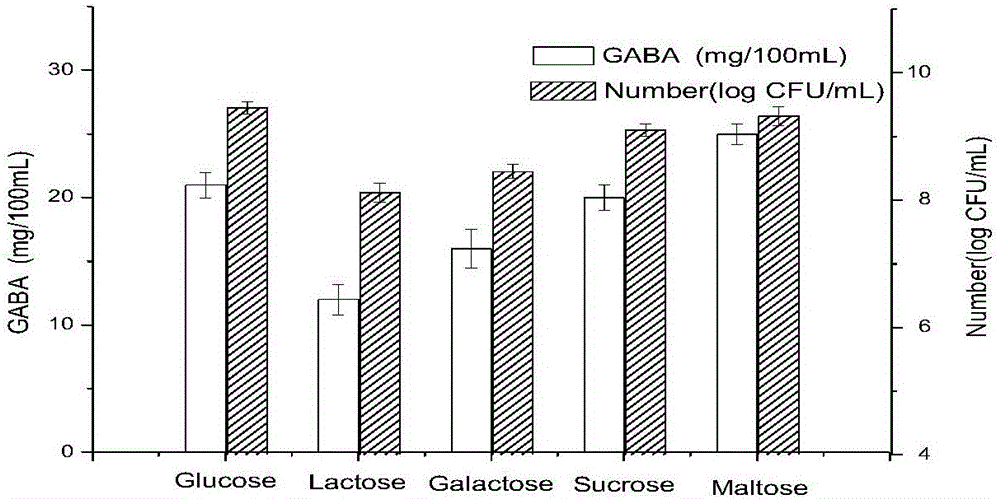

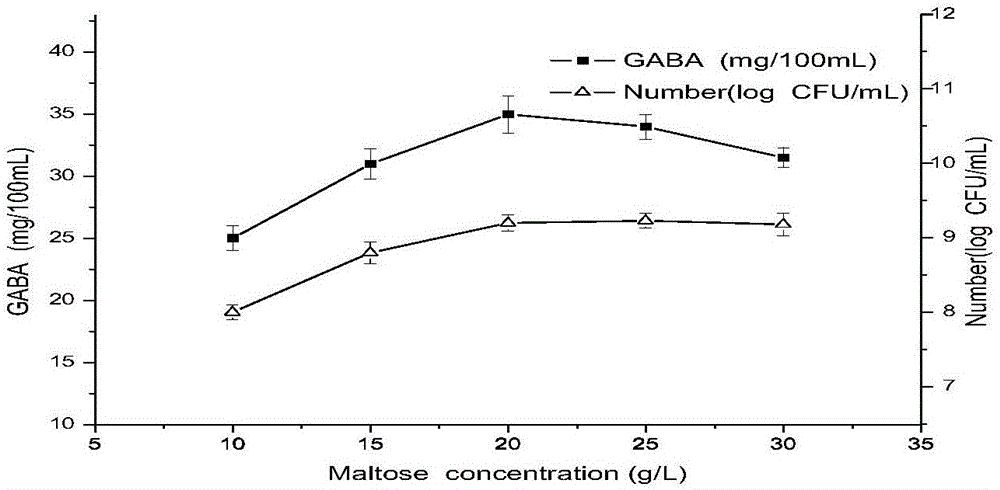

[0061] Glucose, maltose, sucrose, lactose, and galactose were added to the culture medium containing 12% skim milk as the only carbon source for experiments. Effect of Lb.plantarum NDC75017 growth and GABA production. At the same time, the effects of different maltose concentrations on the growth and GABA production of Lactobacillus plantarum NDC 75017 were investigated. Finally, it was confirmed that the optimal carbon source was maltose ( figure 1 ), the addition amount is 20g / L ( figure 2 ).

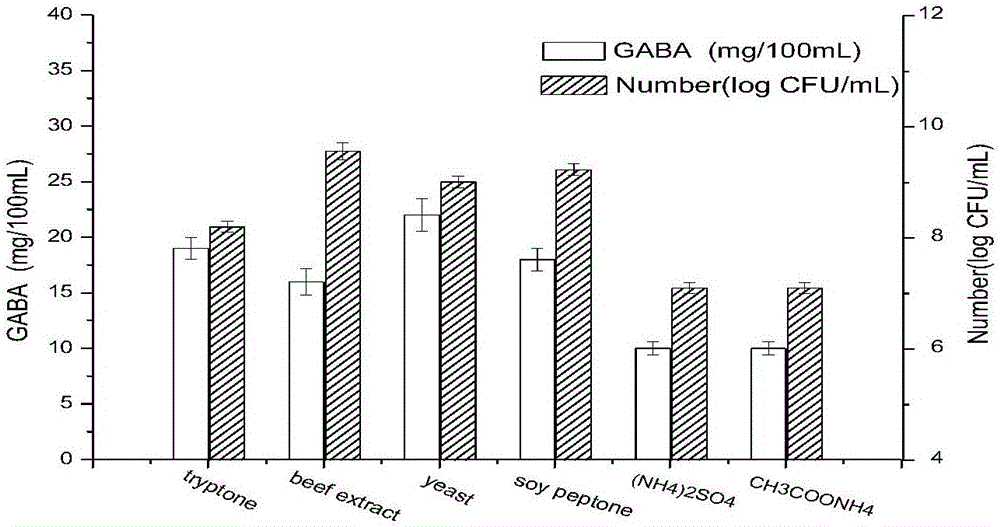

[0062] The effects of different nitrogen sources on the bacterial count of Lb.plantarum NDC 75017 and the mass concentration o...

Embodiment 2

[0065] Example 2: Determination of the optimum fermentation conditions for producing γ-aminobutyric acid

[0066] In this example, the fermentation conditions for producing γ-aminobutyric acid by Lactobacillus plantarum NDC 75017 were optimized to determine the optimum fermentation conditions for producing γ-aminobutyric acid. The effects of sodium glutamate, pyridoxal phosphate and fermentation temperature on the growth of Lactobacillus plantarum NDC75017 and the production of γ-aminobutyric acid were investigated respectively.

[0067] Find by investigating sodium glutamate: sodium glutamate can only promote the synthesis of GABA within a certain range, and the optimum addition amount of sodium glutamate is 75mmol / L ( Figure 8 ).

[0068] By investigating pyridoxal phosphate, it is found that the optimum addition amount of pyridoxal phosphate is 15 μmol / L ( Figure 9 ).

[0069] By investigating the fermentation temperature, it is found that the fermentation temperature ...

Embodiment 3

[0070] Example 3: Comparison of fermentation conditions of Lactobacillus plantarum NDC75017 before and after optimization

[0071] By comparing the fermentation curve of Lactobacillus plantarum NDC75017 before and after optimization (before optimization Figure 11 ,Optimized Figure 12) found that the 0~24h of fermentation belonged to the growth stage of bacteria. During this process, the number of live bacteria of Lb. plantarum (Lb.plantarum) NDC 75017 increased rapidly, and the number of bacteria reached the maximum at 24h, and the number of live bacteria could reach 9.89± 0.87log CFU / mL, an order of magnitude higher than before optimization. Lactobacillus plantarum (Lb.plantarum) NDC 75017 acid production ability is also greatly improved. In the first 9 hours of the fermentation process, the pH of the fermentation broth does not change significantly. When the fermentation time is between 9h and 24h, the pH of the fermentation broth drops rapidly. The lowest point is 4.49,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com