Microbial strain mutation inducing method, clostridium butyricum strains and application of clostridium butyricum strains

A technology of Clostridium butyricum and microorganisms, which is applied in the field of Clostridium butyricum strains and strains of mutagenic microorganisms, can solve the problems of non-directional mutation and inability to increase the frequency of forward mutation, etc., and achieves simple and easy operation, Easy operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This example is an example of a method for mutagenesis of microorganisms. Specifically, it includes the following steps:

[0048] (1) Medium formula

[0049] Growth medium, including liquid medium and solid medium. Liquid medium: glucose 10g / L, yeast powder 8g / L, sodium chloride 2g / L, magnesium sulfate 0.5g / L, pH 6.0; solid medium: liquid medium plus agar 15-20g / L, pH 6. 0.

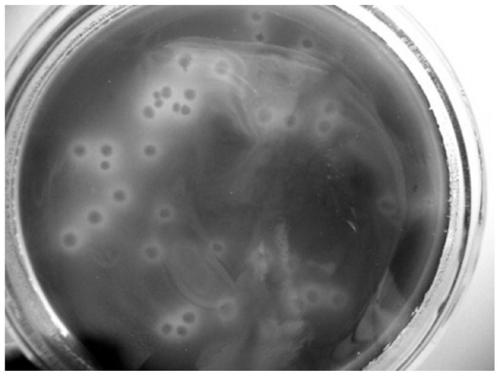

[0050] Screening medium: add 1% calcium carbonate and 0.04% bromocresol purple to the growth medium, pH 7.0.

[0051] (2) Preparation of bacterial suspension: pick a ring of Clostridium butyricum strains preserved in the laboratory, insert it into the growth medium, activate, and culture at 37°C statically, and take the seed solution in the logarithmic growth phase for mutagenesis. Centrifuge the seed solution at 5000 rpm for 5 min, discard the supernatant, wash the precipitate twice with pH 7.0 phosphate buffer, and break up the bacterial cells with glass beads to make 1×10 7 cfu / mL bacterial suspensio...

Embodiment 2

[0060] This example is an application experiment example of Clostridium butyricum.

[0061] Choose 1,000 healthy laying hens with uniform weight and randomly divide them into 2 groups (control group and Clostridium butyricum group), each with 500 chickens. The control group was fed with normal chicken feed, and the Clostridium butyricum group was fed with strain NN-2 at a rate of 0.2 g / Kg on the basis of normal chicken feed. In addition, the chickens in the two experimental groups were free to eat and drink under the same conditions. The test period is 30 days.

[0062] Collect eggs during the laying period, calculate the egg production rate, and randomly select 50 eggs from each group to determine the cholesterol and protein content. The results showed that in the Clostridium butyricum group, the egg production rate increased by 2%; the cholesterol in the eggs was reduced by 33%, and the protein was increased by 22.4%, which significantly improved the quality of the eggs.

Embodiment 3

[0064] This example is an application experiment example of Clostridium butyricum.

[0065] Add 5% white granulated sugar to raw milk preheated to 63-65°C to prepare, stir to dissolve, homogenize, make it more uniform and stable, heat sterilize at 95°C, and take it out after keeping it warm for 10 minutes. When the sterilized raw milk is cooled to 42-45°C, add 6% butyric acid bacteria for inoculation, stir and mix. The inoculated yogurt was fermented and cultured at 37°C at a constant temperature, and the fermentation was terminated after 12h, and then it was taken out and placed in a cold storage at 4°C and cooked for 15h to give the yogurt a good taste and flavor. The butyric acid fermentation yogurt was prepared.

[0066] The prepared butyric acid bacteria fermented yogurt has fine texture, soft mouthfeel, mellow flavor, smooth surface, stable curd, no layering, no whey precipitation, unique yogurt flavor, and rich nutrition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com