High-temperature proton exchange membrane fuel cell and preparation method thereof

A proton exchange membrane and fuel cell technology, applied in the field of electrochemical energy, can solve the problems of reduced porosity, reduced electrical conductivity, and hindered active sites, etc., to achieve the effect of increasing the reaction three-phase interface, improving performance, and reducing occupancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] An embodiment of the present invention provides a method for preparing a high-temperature proton exchange membrane fuel cell, comprising the following steps:

[0029] preparing a binder-free catalyst slurry, coating the catalyst slurry on a gas diffusion layer (GDL), and drying to obtain an electrode; adding acid to the electrode;

[0030] Soak the PBI film in the phosphoric acid solution to obtain the phosphoric acid-doped polybenzimidazole film, which is the soaked film;

[0031] An MEA is composed of the acid-treated electrode and the soaked membrane, and the MEA is assembled into a high-temperature proton exchange membrane fuel cell.

[0032] The preparation method of the high-temperature proton exchange membrane fuel cell provided by the embodiment of the present invention uses the method of adding acid to the electrode without binder, instead of adding the binder when preparing the catalyst layer, and only utilizes the capillary action of the catalyst layer Maint...

Embodiment 1

[0047] The electrode preparation process is as follows: mix 0.0360g Pt / C (40wt%Pt) catalyst with 100mL of absolute ethanol, sonicate at room temperature for at least 1h, so that the catalyst is evenly dispersed in the ethanol solution, and the sonicated solution is transferred to 25mL In the syringe, the liquid flow rate is 0.5mL / min, the temperature of the heating plate is controlled at 60°C, and the distance from the nozzle to the leveling carbon paper is 30mm. Spray the slurry on the carbon paper and place it at room temperature for 12 hours to completely evaporate the ethanol. , to obtain a binder-free electrode with an actual Pt loading of 0.5 mg / cm 2 .

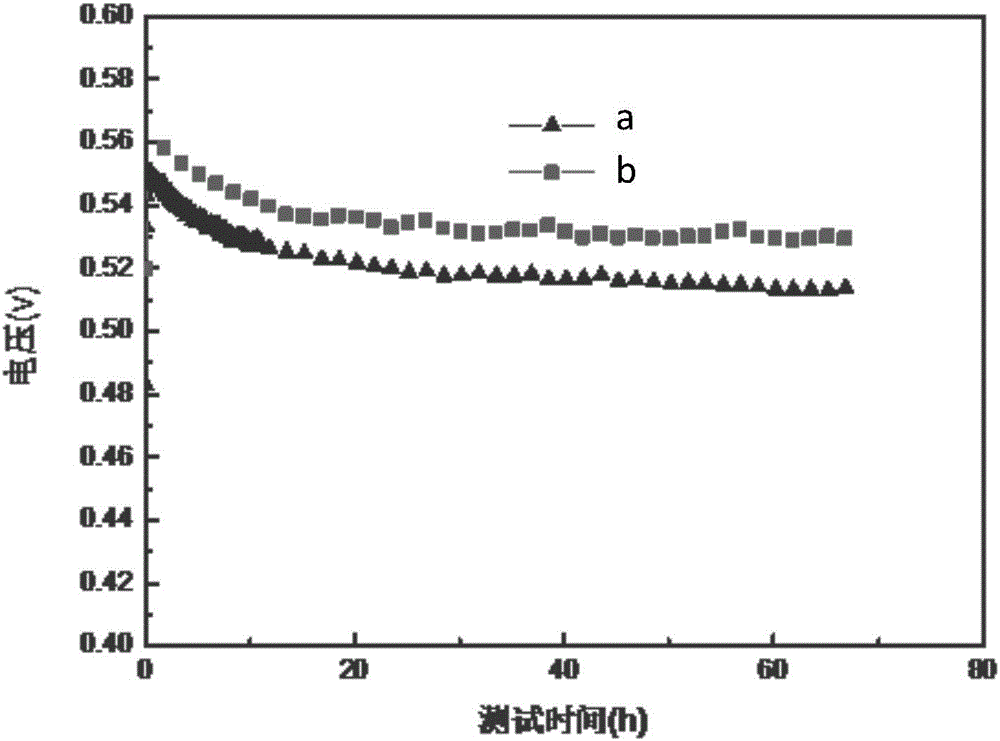

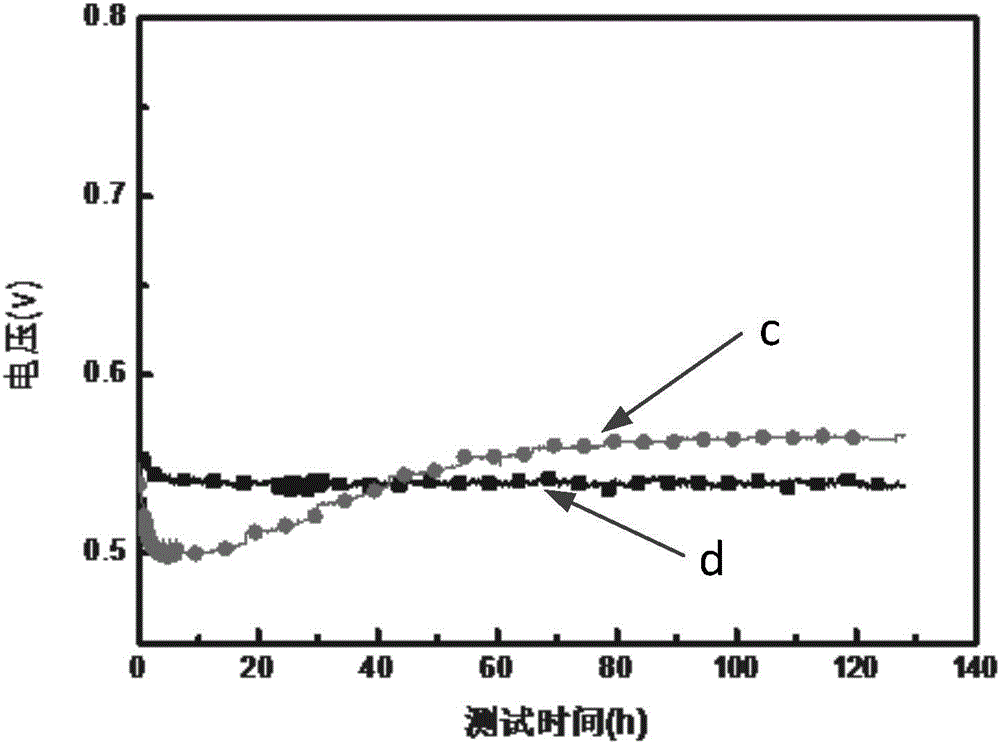

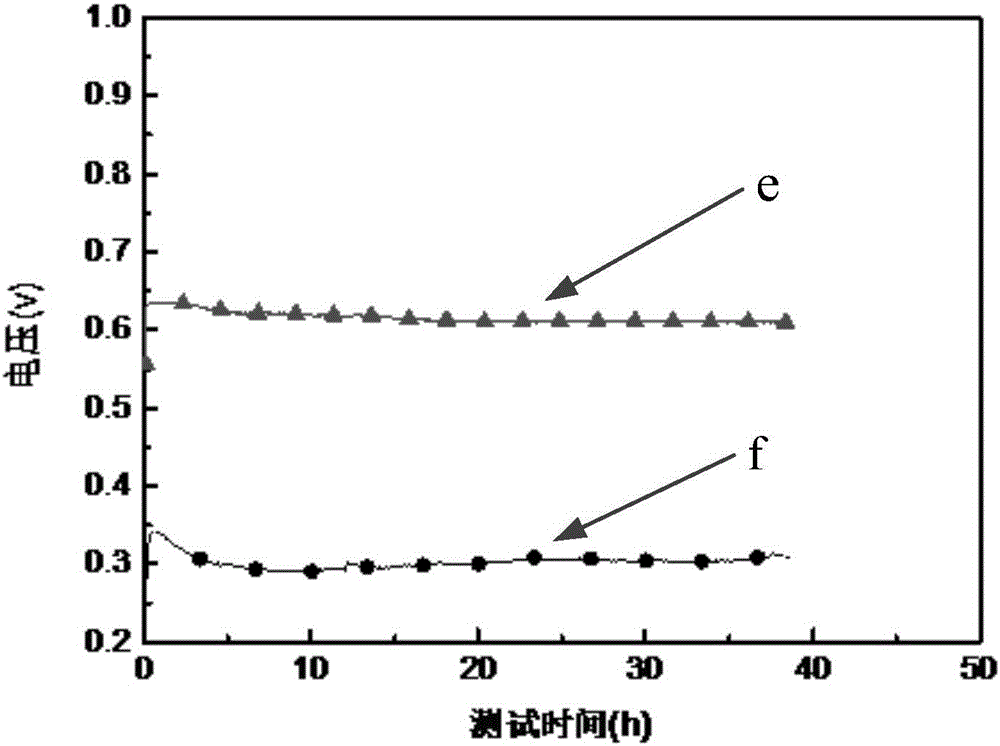

[0048] The preparation process of MEA is as follows: firstly, the 3.5×3.5cm 2 The PBI film was immersed in 85wt% phosphoric acid solution for at least 12 hours, sealed, and the temperature was controlled at 80° C., so that the doping amount of phosphoric acid in the film was 3.5 times. Cut the adhesive-free electrode i...

Embodiment 2

[0052] The electrode preparation process is as follows: mix 0.0838g Pt / C (40wt%Pt) catalyst with 200mL of absolute ethanol, sonicate at room temperature for at least 1h, so that the catalyst is evenly dispersed in the ethanol solution, and the sonicated solution is transferred to 25mL In the syringe, the liquid flow rate is 0.4mL / min, the temperature of the heating plate is controlled at 60°C, and the distance from the nozzle to the leveling carbon paper is 30mm. Spray the slurry on the carbon paper and place it at room temperature for 12 hours to completely evaporate the ethanol. , to obtain a binder-free electrode with an actual Pt loading of 0.67 mg / cm 2 .

[0053] The preparation process of MEA is as follows: firstly, the 3.5×3.5cm 2 The PBI film was soaked in 85wt% phosphoric acid solution for at least 12 hours, sealed, and the temperature was controlled at 80° C. to obtain a soaked film, and the doping amount of phosphoric acid in the film was 3.8 times. Cut the adhesi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com