Power system of combine harvester

A technology of combine harvester and power system, applied in the direction of harvester, transmission element, mechanical equipment, etc., can solve the problems of difficulty in walking, easy to sag, and large space occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

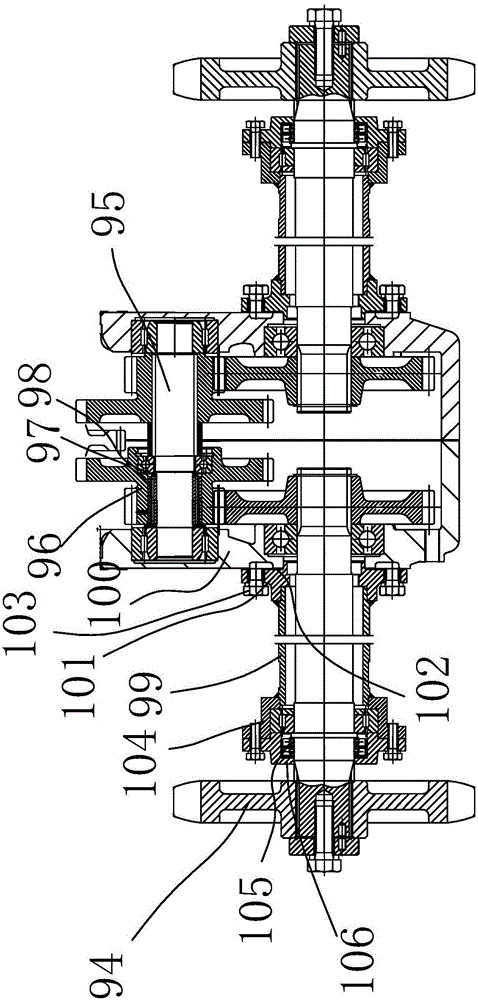

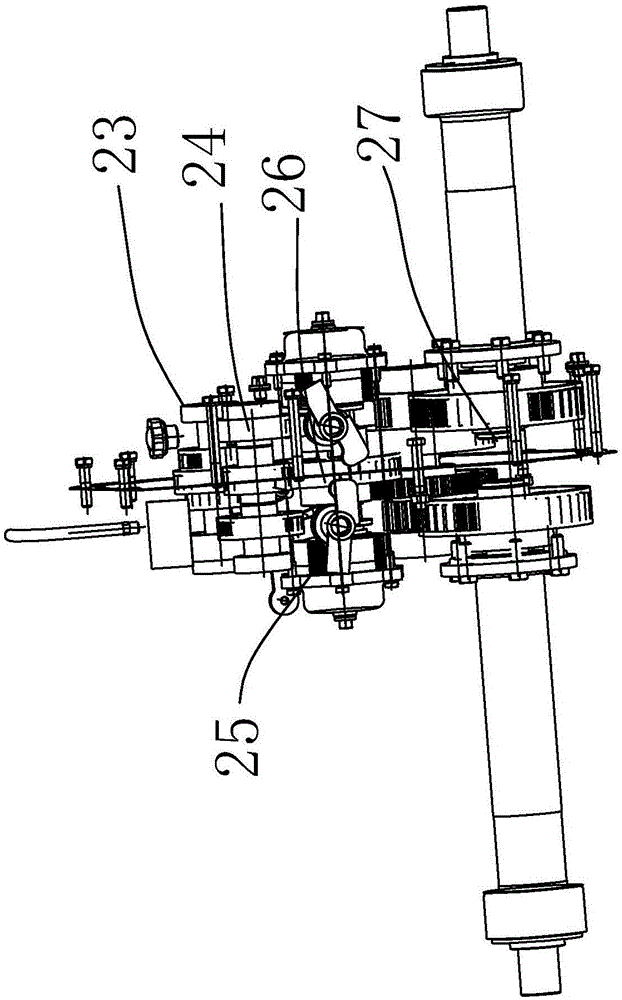

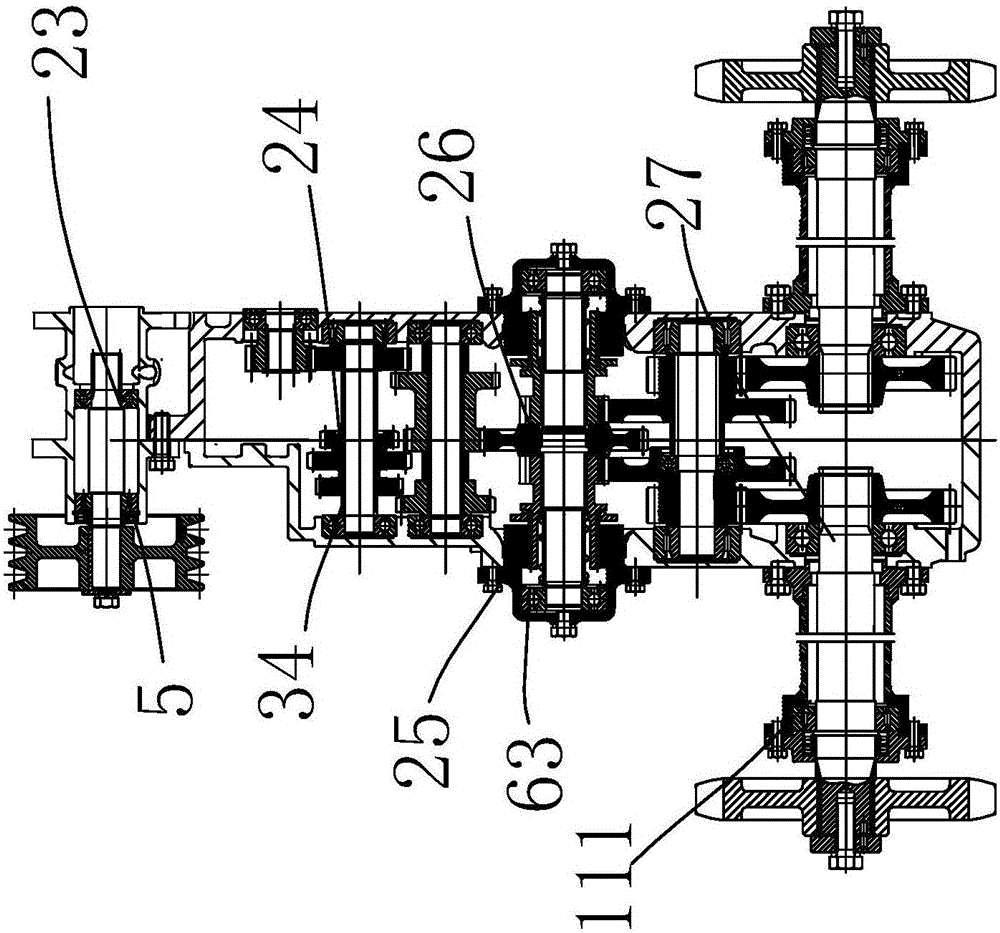

[0087] like image 3 As shown, the power input mechanism of the combine harvester mainly includes a power input shaft 1, an outer casing 2, a power input pulley assembly 3, a continuously variable transmission 4 and a lubrication adjustment assembly 7, and the power input shaft 1 is arranged horizontally and used for rotation, and the outer casing 2 A hollow hole 6 is opened horizontally, and the power input shaft 1 is arranged in the hollow hole 6. The power input pulley assembly 3 is arranged on one end of the power input shaft 1 and is used to connect with an external engine and provide power input. The continuously variable transmission 4 is arranged on the power input shaft. The other end of the rotating shaft 1 is also used to adjust the speed change of the power input rotating shaft 1 .

[0088] The shaft matching mechanism in the power input mechanism 23 is a clearance fit assembly 5, and a clearance fit assembly 5 for adjusting the rotation gap distance of the power i...

Embodiment 2

[0092] Most of the structure of this embodiment is the same as that of Embodiment 1, the difference is that, as Figure 4 As shown, the first clearance fit assembly includes a first rolling bearing 11 and a first transverse clearance elastic member 13, the first transverse clearance elastic member 13 is arranged in the first stepped groove 15, and the two ends of the first transverse clearance elastic member 13 are respectively The function presses on the first rolling bearing 11 and the first stepped groove 15 and is used to adjust the transverse clearance of the first rolling bearing 11. The second clearance fit assembly includes the second rolling bearing 12 and the second transverse clearance elastic member 14. The second transverse clearance elastic The piece 14 is arranged in the second stepped groove 16, and the two ends of the second transverse gap elastic piece 14 respectively press against the second rolling bearing 12 and the second stepped groove 16 and are used to ...

Embodiment 3

[0094] Most of the structure of this embodiment is the same as that of Embodiment 2, the difference is that, as Figure 5 As shown, the clearance fit assembly also includes a longitudinal adjustment bearing 20, which is arranged between the outer casing 2 and the power input shaft 1, and the longitudinal adjustment bearing 20 includes a plurality of alternating rigid layers 22 and gap adjustment layers 21, longitudinally The adjustment bearing 20 includes two gap adjustment layers 21 and three rigid layers 22. The longitudinal adjustment bearing 20 is filled with the gap between the power input shaft 1 and the outer casing 2. The rigid layer 22 here ensures the rotation effect and prevents wear and tear. The gap adjustment layer 21 in the longitudinal adjustment bearing 20 can shrink or expand with the external force, which is equivalent to adjusting the rotation gap between the power input shaft 1 and the outer casing 2, which can prolong the wear life and further improve the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com