Flue gas desulphurization waste liquid spray drying treatment apparatus and treatment method thereof

A desulfurization waste liquid and drying treatment technology, which is applied in the direction of gaseous effluent wastewater treatment, spray evaporation, water/sewage treatment, etc., can solve the problems of complex treatment process, small proportion, evaporation and scaling on the plate of the dust collector, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

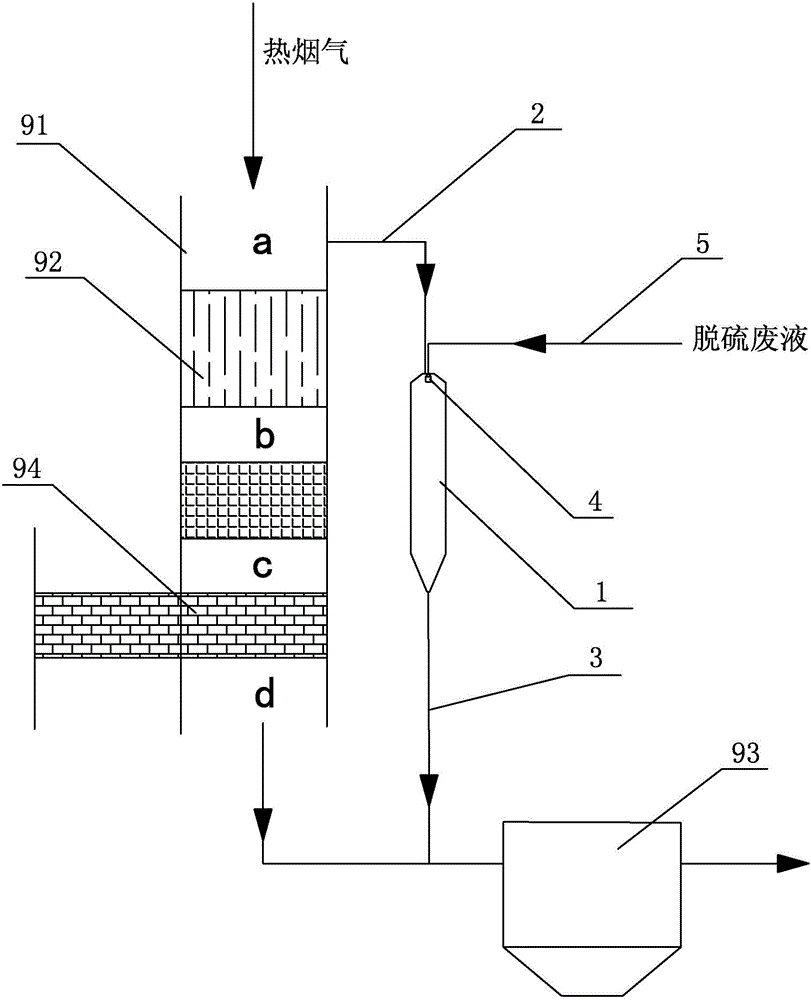

[0021] A kind of flue gas desulfurization waste liquid spray drying treatment device proposed in this embodiment, such as figure 1 As shown, it comprises the spray drying tower 1 that the top has an air inlet and the bottom or the bottom has an air outlet. At the position of the entrance of the economizer 92 provided in the main flue 91 of the kiln) (that is, at the position before the economizer 92, figure 1Middle a place) is communicated with the hot flue gas in the main flue 91 of shunt boiler (furnace kiln), is connected with outlet flue 3 on the gas outlet of spray drying tower 1, and the outlet of outlet flue 3 is connected with boiler (furnace kiln) The downstream of the main flue 91 (that is, the position before the dust collector 93 of the boiler (kiln)) is connected to return the hot flue gas to the main flue 91 of the boiler (kiln), and the top of the spray drying tower 1 A desulfurization waste liquid atomizer 4 is provided, and a desulfurization waste liquid inle...

Embodiment 2

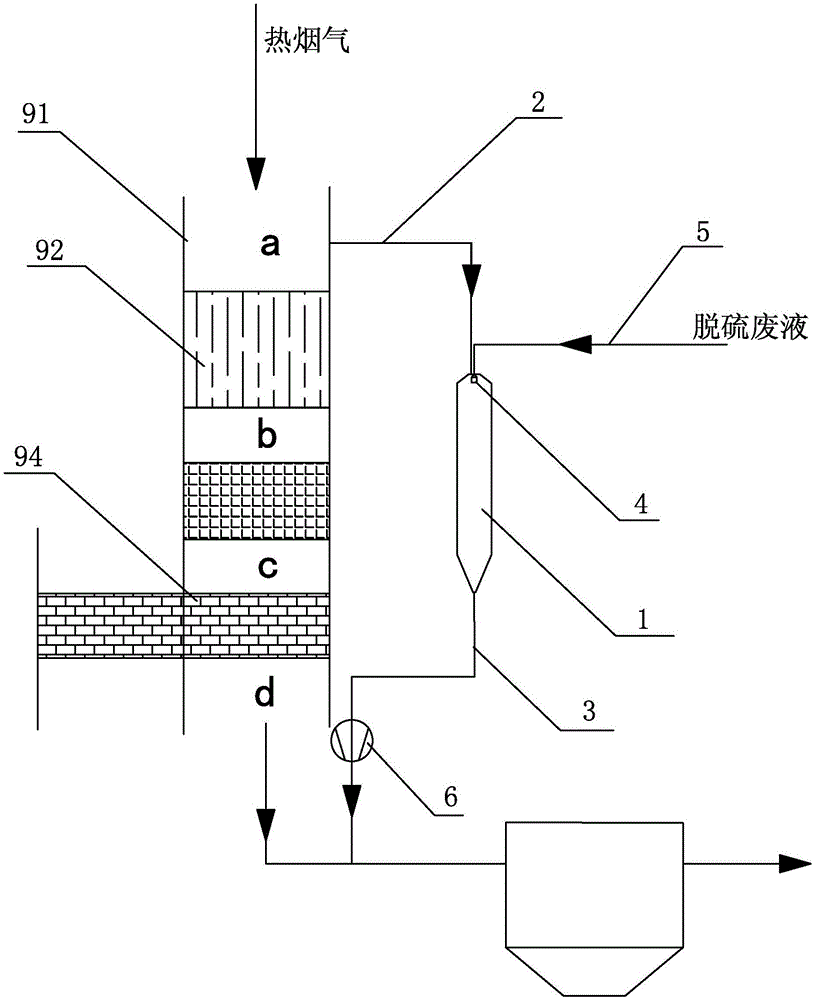

[0023] A flue gas desulfurization waste liquid spray drying treatment device proposed in this embodiment is an improved device after optimizing the flue gas desulfurization waste liquid spray drying treatment device in Example 1. The other structures of the drying treatment device are the same, the only difference is: as figure 2 As shown, an induced draft fan 6 is connected in series on the outlet flue 3 , and the hot flue gas carrying fine powder that enters the outlet flue 3 through the entrance of the outlet flue 3 is transported to the outlet of the outlet flue 3 through the induced fan 6 .

Embodiment 3

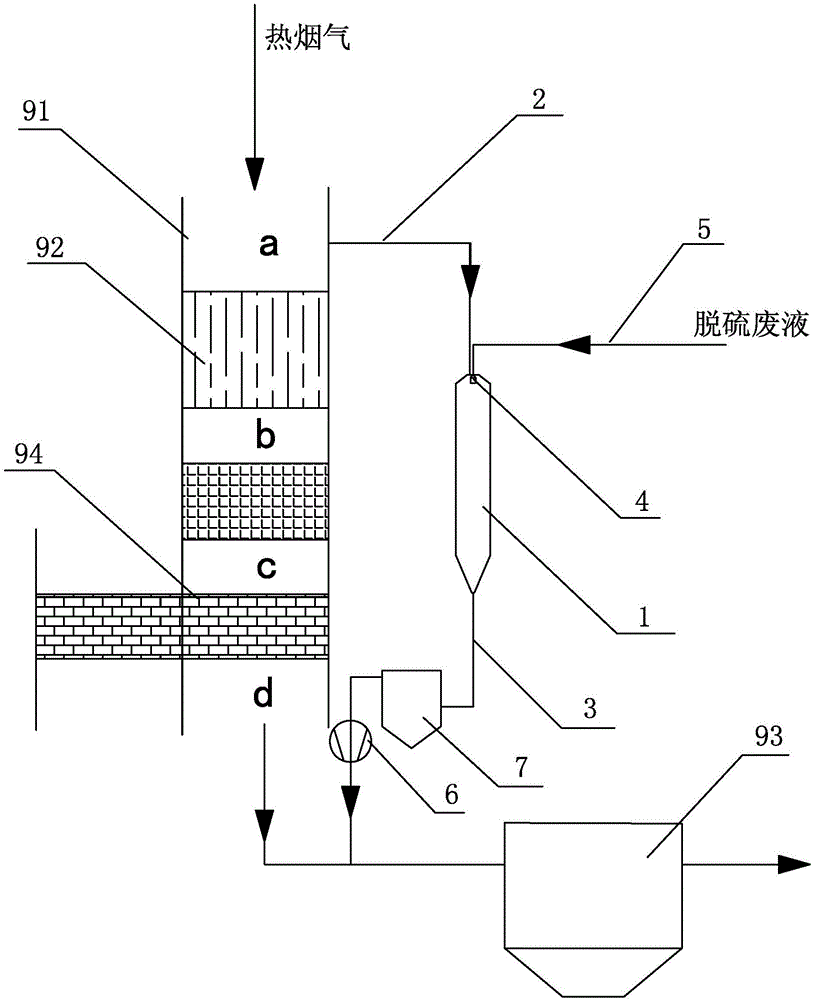

[0025] A flue gas desulfurization waste liquid spray drying treatment device proposed in this embodiment is an improved device after optimizing the flue gas desulfurization waste liquid spray drying treatment device in Example 1. The other structures of the drying treatment device are the same, the only difference is: as image 3 As shown, an auxiliary dust collector 7 and an induced draft fan 6 are sequentially connected in series on the outlet flue 3, and the hot flue gas carrying fine powder that enters the outlet flue 3 through the entrance of the outlet flue 3 is collected by the auxiliary dust collector 7 and carries fine powder. The fine powder in the hot flue gas of powder, the hot flue gas output from the auxiliary dust collector 7 is transported to the outlet of the outlet flue 3 through the induced draft fan 6 . Here, the auxiliary deduster 7 provided can separately collect the fine powder formed by rapid drying of the fine mist of the desulfurization waste liquid, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com