Preparation method and application of in in-situ carbon doped hierarchically structured hollow silicon dioxide/titanium dioxide microspheres

A hierarchical structure, silicon dioxide technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve problems such as poor photoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

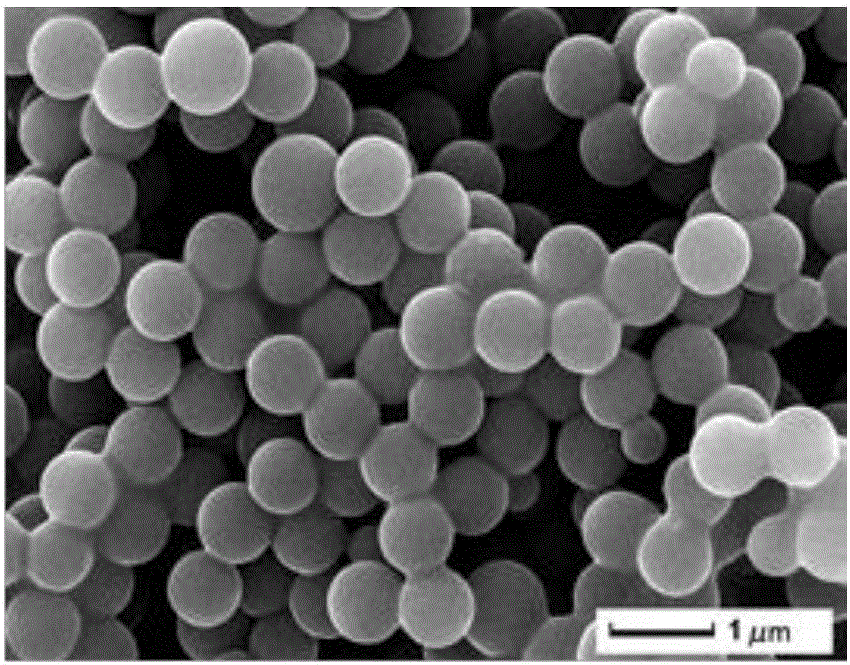

[0051] Put 72g of deionized water, 8g of styrene and 0.16g of potassium persulfate into a 150mL four-necked bottle, and at a stirring speed of 350rpm, pass nitrogen gas to remove the air for about 20 minutes, then place in a constant temperature water bath at 70°C . After reacting for 1.5 hours, under the protection of nitrogen, inject 1.2g of VTC / deionized water mixture (the volume ratio of VTC to deionized water is 1:1) into the reaction bottle with a micro-injector. One injection per hour (10 μL per injection), and then two injections, one injection per hour, each injection is (50 μL). Then the remaining solution was injected every 3 minutes (10 μL) until all the remaining VTC was injected. After the injection was completed, the polymerization was extended for about 12 hours to make it fully polymerized. After the polymerization is completed, the polymer is suction-filtered, washed and separated with a water-based microporous membrane (0.22 μm), and finally monodisperse ca...

Embodiment 2

[0053] Preparation of Hierarchical Carbon-Doped Hollow Silica / Titania (SiO 2 / C-TiO 2 ).

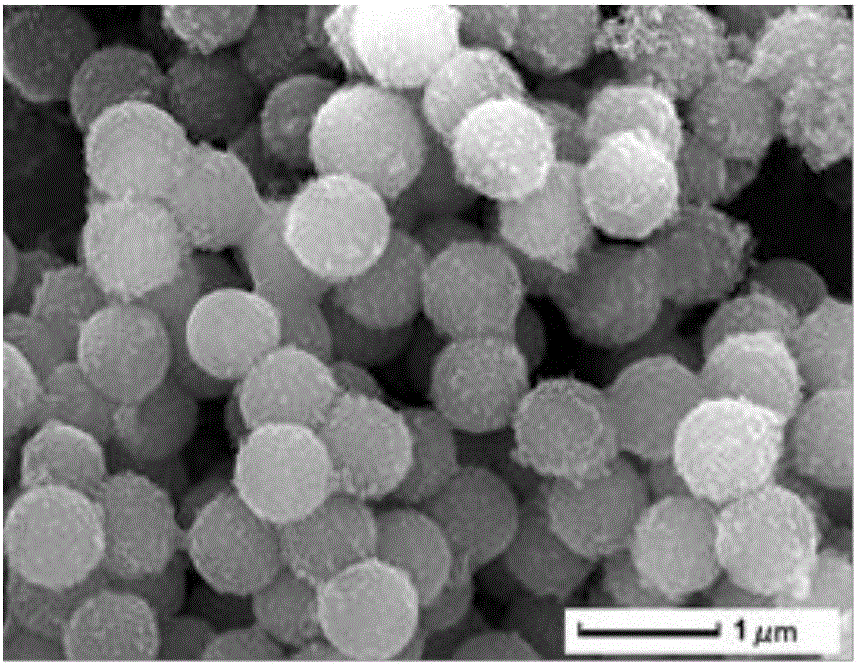

[0054] CPS / SiO2 2 Preparation: In a 100mL four-neck flask, add 3.2g of CPS template and disperse it in 40mL of ethanol, control the temperature of the system at 50°C, add 3mL of ammonia water with a mass fraction of 25% as a catalyst, slowly add 0.8g of CPS under mechanical stirring After reacting for 4 hours, add 0.2mL allyltriethoxysilane under nitrogen protection, react for 6 hours, cool to room temperature, centrifuge, wash and dry to prepare functional CPS / SiO 2 Core-shell microspheres; such as figure 2 ;

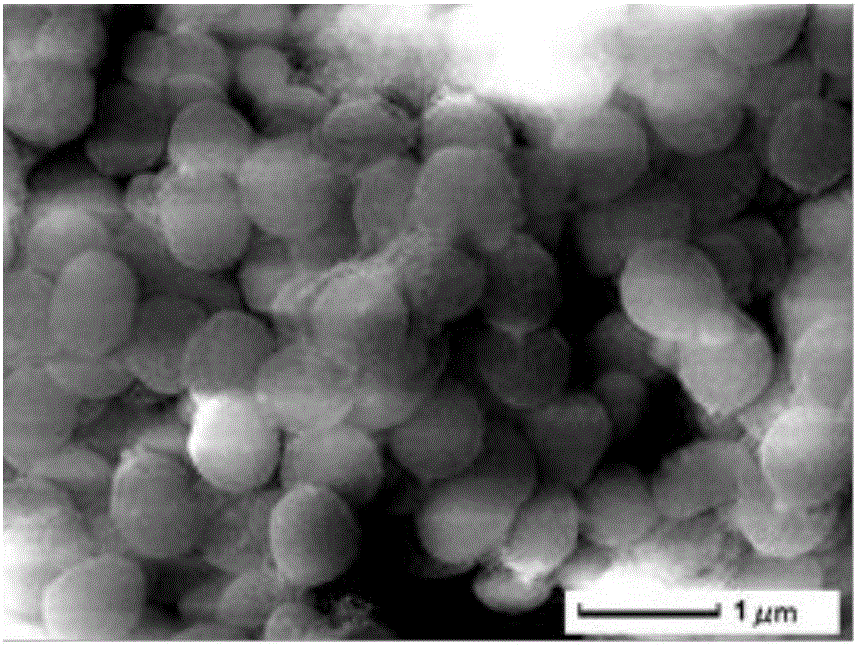

[0055] CPS / SiO2 2 / CPS synthesis: In a 100mL four-neck flask, add 2g CPS / SiO 2 And dispersed in 40mL of ethanol, under the protection of nitrogen and mechanical stirring, the reaction temperature was raised to 50°C, then 2g of styrene monomer and 0.02g of initiator AIBN were added, and the temperature was raised to 70°C. After reacting for 1.5h, add dropwise a mixture of ...

Embodiment 3

[0059] Preparation of Hierarchical Carbon-Doped Hollow Silica / Titania (SiO 2 / C-TiO 2 ).

[0060] CPS / SiO2 2 Preparation: In a 100mL four-neck flask, add 3.2g of CPS template and disperse it in 40mL of ethanol, control the temperature of the system at 50°C, add 3mL of ammonia water with a mass fraction of 25% as a catalyst, slowly add 0.8g of CPS under mechanical stirring After reacting for 5 hours, add 0.2mL allyltriethoxysilane under nitrogen protection, react for 6 hours, cool to room temperature, centrifuge, wash and dry to prepare functional CPS / SiO 2 Core-shell microspheres;

[0061] CPS / SiO2 2 / CPS synthesis: In a 100mL four-neck flask, add 2g CPS / SiO 2 And dispersed in 40mL of ethanol, under the protection of nitrogen and mechanical stirring, the reaction temperature was raised to 50°C, then 2g of styrene monomer and 0.02g of initiator AIBN were added, and the temperature was raised to 70°C. After reacting for 1.5h, add dropwise a mixture of 0.75g of DMC and 0.75...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com