Stabilizer for preparing sagittaria sagittifolia beverage, and preparation method and application thereof

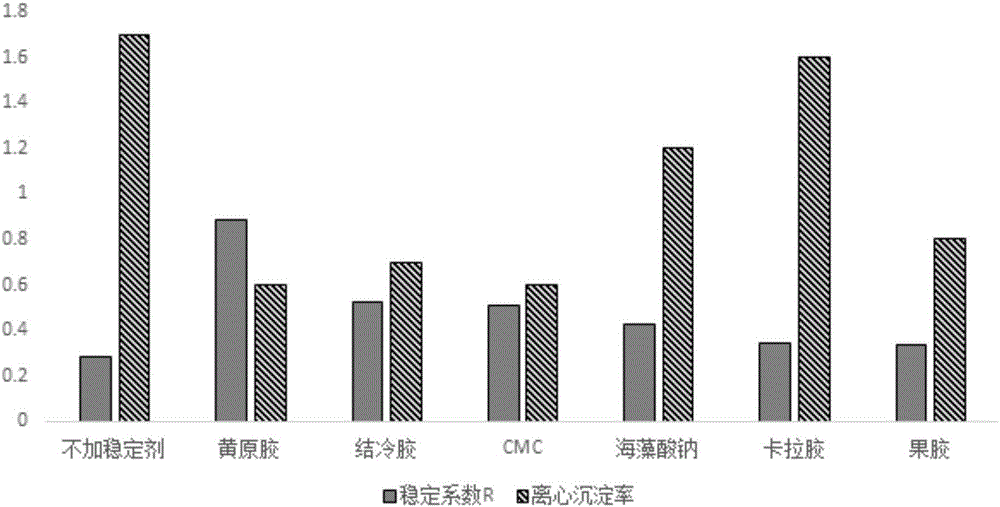

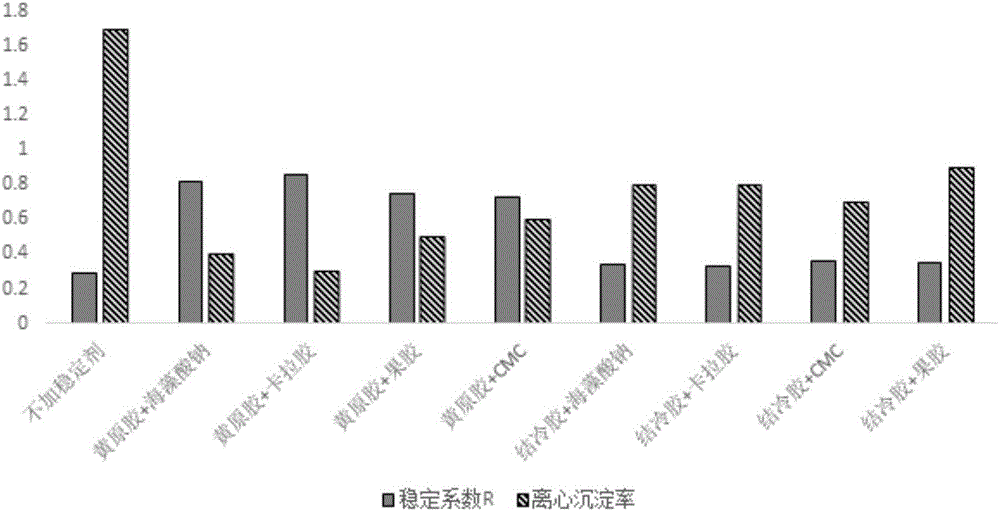

A stabilizer and technology of sagittarius, applied in the field of stabilizer and preparation of sagittarius beverage, can solve problems such as stratification and starch precipitation, and achieve the effects of reducing precipitation, maintaining uniformity of the system, and excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Wash fresh Sagittarius raw materials, peel them, and cut them into small pieces of 0.5-1.0cm. Take 40kg of pretreated raw materials and add them to boiled pure water according to the material-to-liquid ratio of 1g:5mL, pre-boil for 5-6 minutes, and pass the pre-boiled water through a 300-mesh nylon mesh sieve. The filtrate is reserved for later seasoning, and the pre-boiled Sagittarius pulp was added to pure water at a ratio of 1g:1.5mL for beating. Use citric acid and sodium citrate to prepare a buffer solution with a pH of 6, and add it according to 1 / 4 of the volume of sagittarius pulp. After the center temperature of Arrowhead pulp reaches 80°C, add α-amylase at a ratio of 120U per gram of Arrowhead pulp (calculated by raw material weight), and liquefy at 80°C for 30 minutes; use citric acid and sodium citrate to prepare a buffer with a pH of 4.4 Liquid, add according to the volume 1 / 8 of Sagittarius pulp. After the center temperature of Sagittarius pulp reaches 6...

Embodiment 2

[0031] Weigh xylitol, xanthan gum, sodium alginate, carboxymethyl Sodium cellulose cellulose (CMC) is dry mixed, dissolved in pure water at 80-85°C, and stirred under a high-speed shear mixer for 15-20 minutes to fully dissolve it; , The volume ratio of the stabilizer is 2:3:5 and mixed to obtain a mixed solution; add citric acid to the mixed solution, and add 0.01g of citric acid to every 100mL mixed solution; circulate and homogenize twice under 20MPa pressure, degas Filling, high temperature and high pressure sterilization at 121°C for 5 minutes.

Embodiment 3

[0033] Xylitol, xanthan gum, sodium alginate, carboxymethyl Sodium cellulose cellulose (CMC) is dry mixed, dissolved in pure water at 80-85°C, and stirred under a high-speed shear mixer for 15-20 minutes to fully dissolve it; , The volume ratio of the stabilizer is 2:3:5 and mixed to obtain a mixed solution; add citric acid to the mixed solution, and add 0.01g of citric acid to every 100mL mixed solution; circulate and homogenize twice under 20MPa pressure, degas Filling, high temperature and high pressure sterilization at 121°C for 5 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com