Calcium oral cavity rapid-dissolving membrane agent and preparation method thereof

An oral instant film and calcium source technology, applied in the fields of medicine, health care, and food, can solve the problems of low efficacy and utilization rate of calcium tablets, existence of first pass effect, and unsatisfactory absorption rate, and achieve good palatability and onset of effect. Fast, palatable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

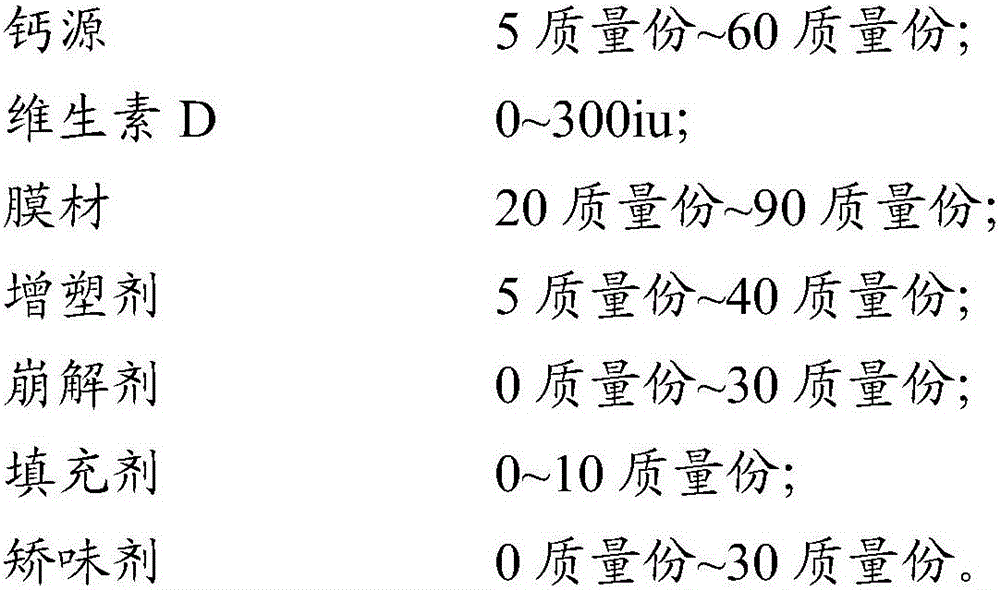

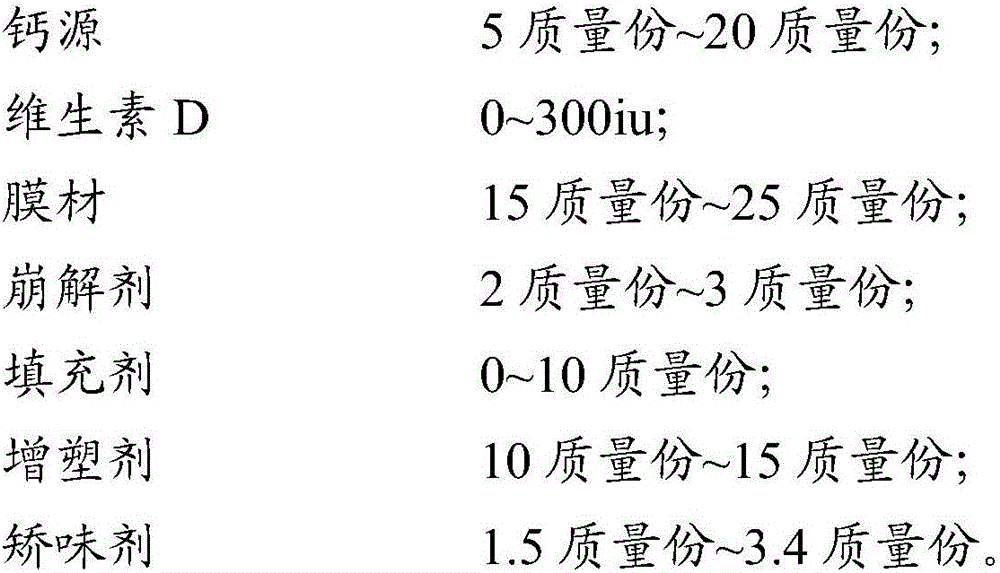

Method used

Image

Examples

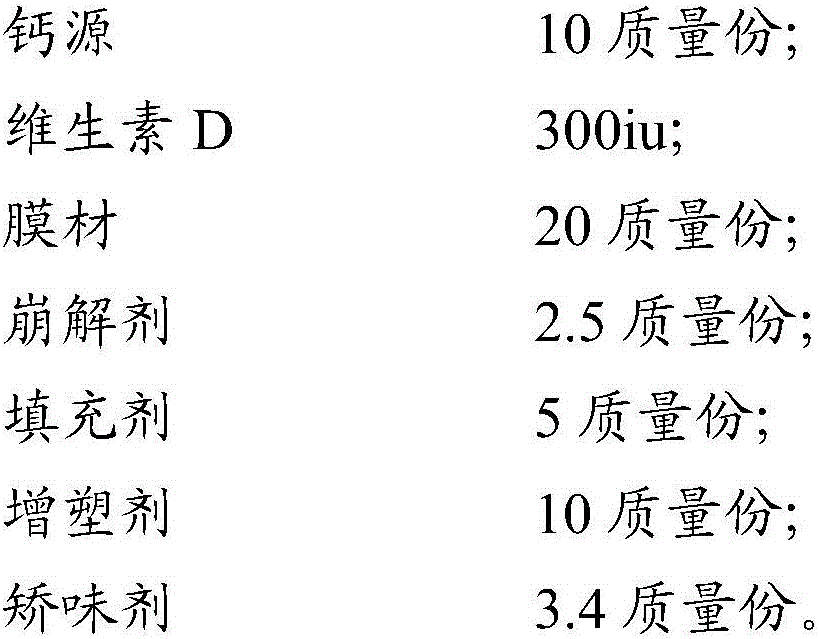

Embodiment 1

[0065] The prescription quantity is 1000 tablets (each tablet contains 10mg of calcium citrate)

[0066]

[0067] Freeze-drying method: Weigh each component according to the formula, add 500g of water to dissolve, stir while adding, after stirring evenly, degas, apply the above-mentioned calcium citrate suspension on the plate evenly, and place it for freeze-drying In the machine for 30 minutes, cut (2cm×2cm) to obtain calcium oral instant film.

[0068] The film has good flexibility, melts and disperses quickly at the entrance, has a good taste and sweet taste, and the melting time in water at 37°C is 30s.

Embodiment 2

[0070] The prescription quantity is 1000 tablets (calcium lactate content per tablet is 6mg)

[0071]

[0072] Solvent casting method: according to the recipe, take the film-forming material polyvinyl alcohol and dissolve it in 500g of water to make a uniform viscous liquid. Under the action of a high-speed mixer, disperse other ingredients evenly in a small amount of water, then add to the above viscous liquid to form a uniform viscous liquid, and then vacuumize. The forming solution was coated on the casting film, dried and cut.

[0073] The film has good flexibility, melts and disperses quickly at the entrance, has a good taste and sweet taste, and the melting time in water at 37°C is 15s to 20s.

Embodiment 3

[0075] The prescription quantity is 1000 tablets (each chelated calcium content is 20mg)

[0076]

[0077] Hot-melt extrusion method: Weigh each component according to the formula and add it from the hopper to the feeding area of the single-screw or twin-screw extruder, and send it into the hot-melt area to melt and mix well. The molten mixture is continuously output through the batching area. Put on film, cool, and cut.

[0078] The film has good flexibility, melts and disperses quickly at the entrance, has a good taste and sweet taste, and the melting time in water at 37°C is 15s to 20s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com