Platinum macroporous aluminum oxide catalyst for preparing propylene through propane dehydrogenation

A macroporous alumina and propane dehydrogenation technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, catalyst activation/preparation, etc., can solve the limitation of chromium catalyst use and short catalyst life , selectivity is not high, to achieve small distribution, reduce the rate of carbon deposition or coking reaction, the effect of fast diffusion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

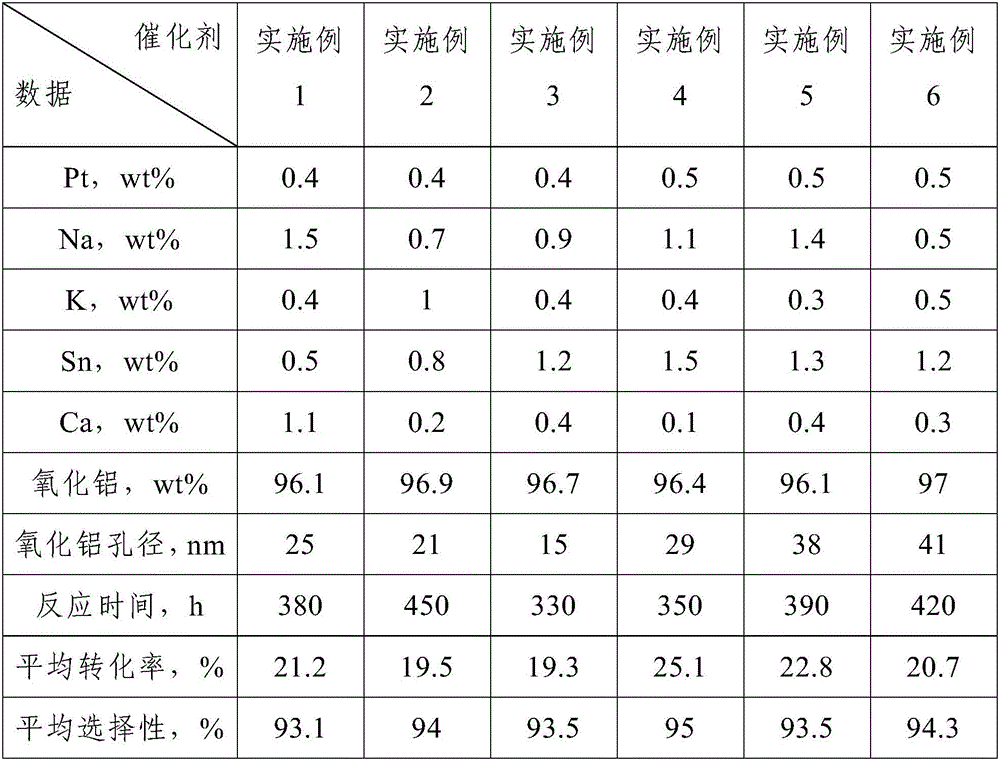

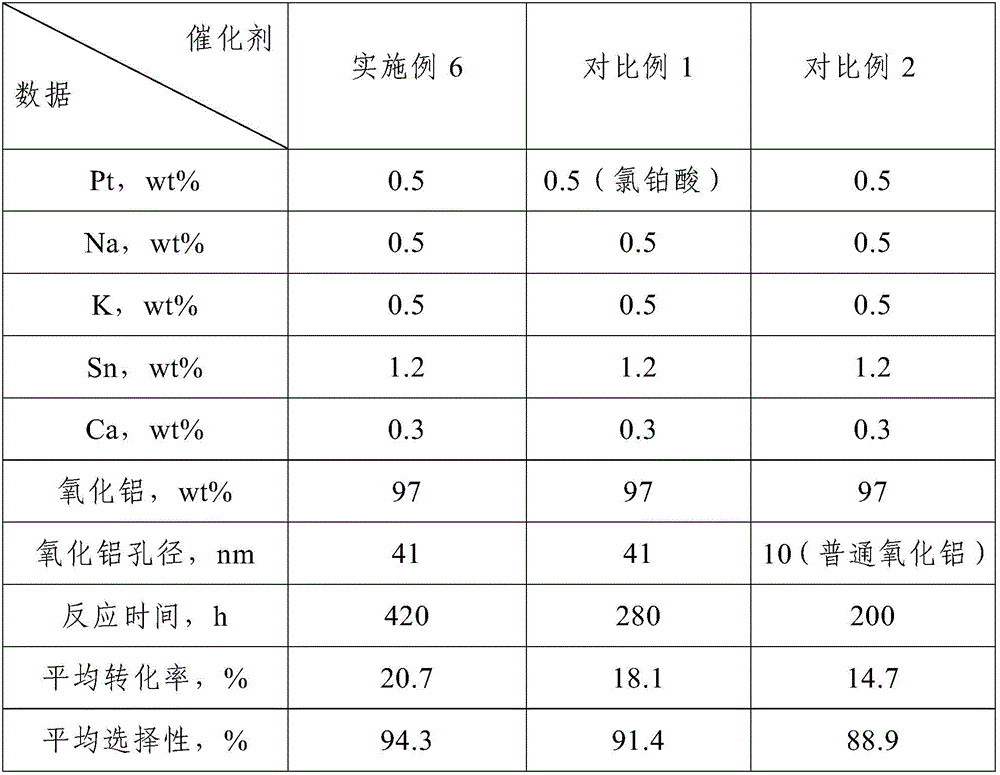

[0018] The platinum macroporous alumina catalyst for propane dehydrogenation to propylene provided in this example uses macroporous alumina with a diameter of 1.3 mm to 1.4 mm and a pore diameter of 25 nm as the carrier, Pt as the active component, and Na as the first catalyst. As the auxiliary agent, the metal M is used as the second auxiliary agent, and the M is K, Ca and Sn. The mass percentage of each component in the catalyst is shown in Table 1. The catalyst is prepared by a spraying-roasting method, and the specific process of the spraying-roasting method is as follows: 0.68g dinitrosodiammine platinum, 3.81g sodium chloride, 0.76g potassium chloride, 1.1g tin chloride Add 3.05g of calcium chloride and 3.05g of calcium chloride into hot water at a temperature of 35°C, stir evenly, spray it on the macroporous alumina, then place it in a muffle furnace, and roast it at a temperature of 700°C for 4 hours to obtain the depropane Platinum macroporous alumina catalyst for hyd...

Embodiment 2

[0020] The platinum macroporous alumina catalyst for propane dehydrogenation to propylene provided in this example uses macroporous alumina with a diameter of 1.3 mm to 1.4 mm and a pore diameter of 21 nm as the carrier, Pt as the active component, and Na as the first catalyst. As the auxiliary agent, the metal M is used as the second auxiliary agent, and the M is K, Ca and Sn. The mass percentage of each component in the catalyst is shown in Table 1. The catalyst is prepared by a spraying-roasting method, and the specific process of the spraying-roasting method is as follows: 0.68g dinitrosodiammine platinum, 1.78g sodium chloride, 1.91g potassium chloride, 1.76g tin chloride Add 0.56g calcium chloride and 0.56g calcium chloride into hot water at a temperature of 50°C, stir evenly, spray it on the macroporous alumina, then place it in a muffle furnace, and roast it at a temperature of 600°C for 5 hours to obtain the depropane Platinum macroporous alumina catalyst for hydrogen...

Embodiment 3

[0022] The platinum macroporous alumina catalyst for propane dehydrogenation to propylene provided in this example uses macroporous alumina with a diameter of 1.3 mm to 1.4 mm and a pore diameter of 15 nm as the carrier, Pt as the active component, and Na as the first catalyst. As the auxiliary agent, the metal M is used as the second auxiliary agent, and the M is K, Ca and Sn. The mass percentage of each component in the catalyst is shown in Table 1. The catalyst is prepared by a spraying-roasting method, and the specific process of the spraying-roasting method is as follows: 0.68g dinitrosodiammine platinum, 2.29g sodium chloride, 0.76g potassium chloride, 2.63g tin chloride and 1.11g of calcium chloride were added to hot water at a temperature of 60°C, stirred evenly, and then sprayed onto macroporous alumina, then placed in a muffle furnace, and roasted at a temperature of 400°C for 8 hours to obtain depropane Platinum macroporous alumina catalyst for hydrogen to propylene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com