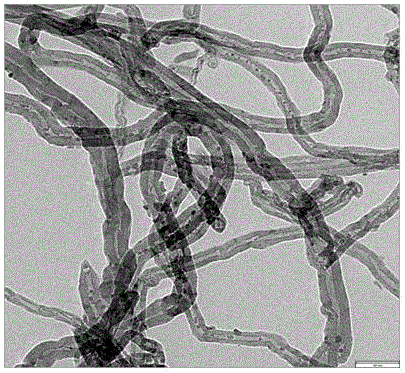

Preparation method of Co particle coated CNT (carbon nanotube) catalytic material and application of catalytic material in cyclohexane oxidation reaction

A technology of carbon nanotubes and catalytic materials, which is applied in the direction of hydrocarbon oxidation to prepare oxygen-containing compounds, oxidation reaction preparation, and carbon-based compound preparation. It can solve the problems of low conversion rate, increased separation energy consumption, and unsuitability for industrial production. Not easy to lose, improve catalytic activity, and improve yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Co@OCNTs for Catalyzing Cyclohexane Oxidation

[0039] (1) Take 2g of carbon nanotubes in a 250ml round bottom flask, add 100ml of concentrated nitric acid solution (mass fraction 65%~68%), and reflux at 100°C for 16h;

[0040] (2) After the reflux is completed, cool to room temperature, filter and wash with deionized water several times until neutral;

[0041] (3) drying the solid obtained in step (2) at 110° C. for 12 hours to obtain oxidized carbon nanotubes (OCNTs);

[0042] (4) Dissolve 1.3g of cobalt nitrate in 20ml of absolute ethanol to make 0.223mol / L ethanol solution of cobalt nitrate;

[0043] (5) Take 0.5g of OCNTs obtained in step (3) in a small beaker, place the small beaker in an ultrasonicator, and add 2ml of cobalt nitrate ethanol solution dropwise to the small beaker with a rubber dropper under ultrasonication and stirring , then add 1.5ml of deionized water dropwise under ultrasonic stirring;

[0044] (6) Ultrasound for 30 minutes, then stand still...

Embodiment 2

[0055] The difference from Example 1 is that the reaction temperature is 145° C. and the reaction pressure is 1.0 MPa.

[0056] The results showed that the conversion rate of cyclohexane was 7.06%, and the total selectivity of product alcohols and ketones was 54.93%.

Embodiment 3

[0058] The difference from Example 1 is that the reaction temperature is 155° C. and the reaction pressure is 0.8 MPa.

[0059] The results showed that the conversion rate of cyclohexane was 8.95%, and the total selectivity of product alcohols and ketones was 74.92%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com