Bottled drinking water plastic buckle automatic pick-and-place device

An automatic pick-and-place, drinking water technology, used in antifouling/underwater coatings, transportation and packaging, biocide-containing paints, etc., can solve the problems of low work efficiency, poor cleanliness, high labor costs, and achieve hygienic conditions Improvement, high hardness, good bacteriostatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

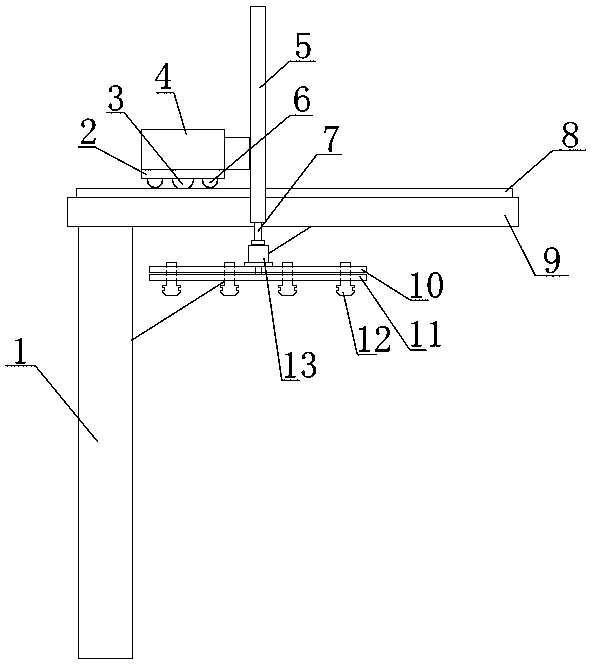

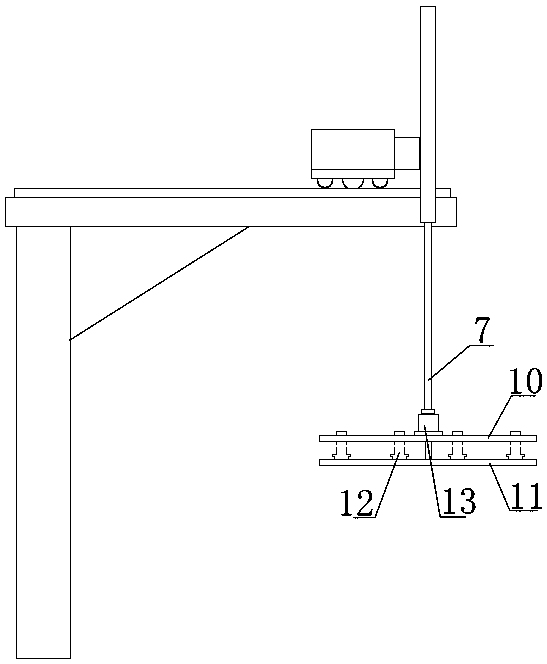

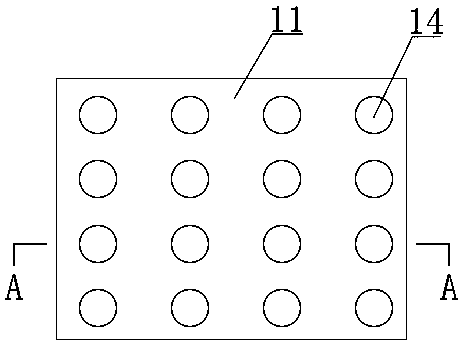

[0028] refer to Figure 1 to Figure 5 , the present invention includes a bracket 1 with a beam 9 at the top; horizontal slide rails 8 and racks corresponding to each other are provided on the beam 9; tackle 2; said tackle 2 is provided with a motor 4, and the gear 3 provided on the rotating shaft of the motor 4 and the rack on the crossbeam 9 are in meshing transmission connection; the front end of said tackle 2 is provided with a reclaiming cylinder 5, and The bottom of material cylinder 5 telescopic arm 7 is provided with blanking cylinder 13; The bottom surface of described blanking cylinder 13 is fixedly provided with fastening plate 10; The hole and the pusher plate 11 are fixedly connected to each other, and the fastening plate 10 and the pusher plate 11 fit up and down; There are holes 14 corresponding to the retrieving deck 12; the outer wall of the bottom end of the retrieving deck 12 and the bottom surface of the pushing plate 11 are respectively provided with a nan...

Embodiment 2

[0040] A nano antibacterial coating, which is prepared according to the following process:

[0041] Mix nano-silver powder, nano-zinc oxide and nano-silica gel powder evenly according to the weight ratio of 5:3:2 to obtain a nano-composite material;

[0042] Mix quartz sand, diatomaceous earth and dolomite at a mass ratio of 3:2:2, then calcinate at 800°C for 30 minutes, take it out, cool to room temperature, then mix nanocomposites at a mass ratio of 8:1, and let stand for 30 minutes , then add 1M sulfuric acid of the same quality, soak for 15min, filter, and dry to obtain component A;

[0043] Add sodium carboxymethylcellulose, isopropanol, ethanol, polydimethylsiloxane, vinyltrimethoxy Base silane, butyl acetate, acrylic resin and deionized water, stirred at 1000rpm for 5min to obtain component B;

[0044] Add component A to component B, stir at 1500rpm for 10min, stop stirring, heat up to 60°C, keep warm for 30min, cool down to room temperature naturally, and seal the pa...

Embodiment 3

[0046] Bacteriostasis test of the nano antibacterial coating prepared by Example 2 of the present invention: the test material is divided into two groups, respectively, a control group and a test group, and the size is 40 × 40 × 5mm. The control group does not do any treatment, and the test group is sprayed with this Invented paint, the thickness of the coating is 100um. All the test materials were placed in a petri dish, and the bacterial solution was dropped on a sterile plate, incubated in an incubator for 180min, then taken out, and counted under a microscope. The bactericidal ability of the coating is judged by the number of colonies. The lower the number of colonies, the stronger the bactericidal ability. Take Escherichia coli and Staphylococcus aureus as examples, see Table 1 for details:

[0047] Table 1

[0048] group

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com