Hot-dip galvanizing waste acid resource treatment method

A treatment method, hot-dip galvanizing technology, which is applied in metallurgical wastewater treatment, energy wastewater treatment, chemical instruments and methods, etc., can solve the problems of inability to effectively recycle waste acid iron, inability to promote industrial application, and high cost, so as to facilitate recycling , Efficient recycling, and the effect of reducing the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The composition of waste acid in a hot-dip galvanizing plant is as follows:

[0039] List of waste acid components (concentration unit: mg / L)

[0040] components Fe 2+

Fe 3+

Ni sn total copper total zinc Pb acidity concentration 120000 5000 200 1.59 15.4 16.4 40 55370

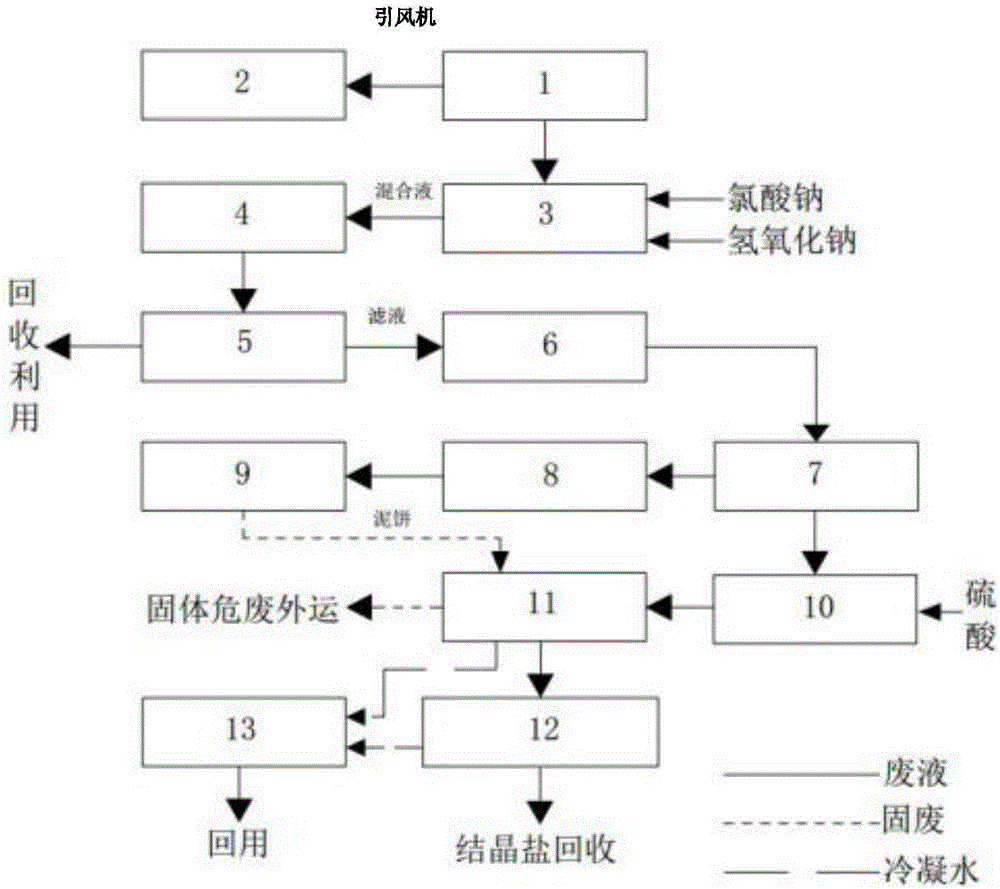

[0041] Process flow of waste hydrochloric acid:

[0042] (1) Collect the volatile acid mist in the upper part of the acid mist collection pool 1 through the induced draft fan to the acid mist absorption tower absorption 2 to form acid liquid, and the acid liquid enters the first medium through the liquid outlet of the acid mist absorption tower absorption 2 And in the reaction pool 3;

[0043] (2) Add sodium chlorate (mass fraction 28%) and sodium hydroxide (mass fraction 30%) in the first neutralization reaction tank 3 to adjust pH to 4.5, and sodium chlorate oxidizes ferrous ion to ferric iron According to the solubility product constant of metal io...

Embodiment 2

[0048] The composition of waste acid in a hot-dip galvanizing plant is as follows:

[0049] List of waste acid components (concentration unit: mg / L)

[0050] components Fe 2+

Fe 3+

Ni total copper total zinc Pb acidity concentration 200000 1000 285 15.4 2000 40 55370

[0051] Process flow of waste hydrochloric acid:

[0052] (1) Collect the volatile acid mist in the upper part of the acid mist collection pool 1 through the induced draft fan to the acid mist absorption tower absorption 2 to form acid liquid, and the acid liquid enters the first medium through the liquid outlet of the acid mist absorption tower absorption 2 And in the reaction pool 3;

[0053] (2) Add sodium chlorate (mass fraction 28%) and sodium hydroxide (mass fraction 30%) in the first neutralization reaction tank 3 to adjust pH to 4.5, and sodium chlorate oxidizes ferrous ion to ferric iron According to the solubility product constant of metal ions, ferric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com