Coking wastewater treatment process and system

A technology for coking wastewater and treatment process, which is applied in special compound water treatment, water/sewage treatment, anaerobic digestion treatment, etc. The effect of reducing energy consumption and high biochemical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

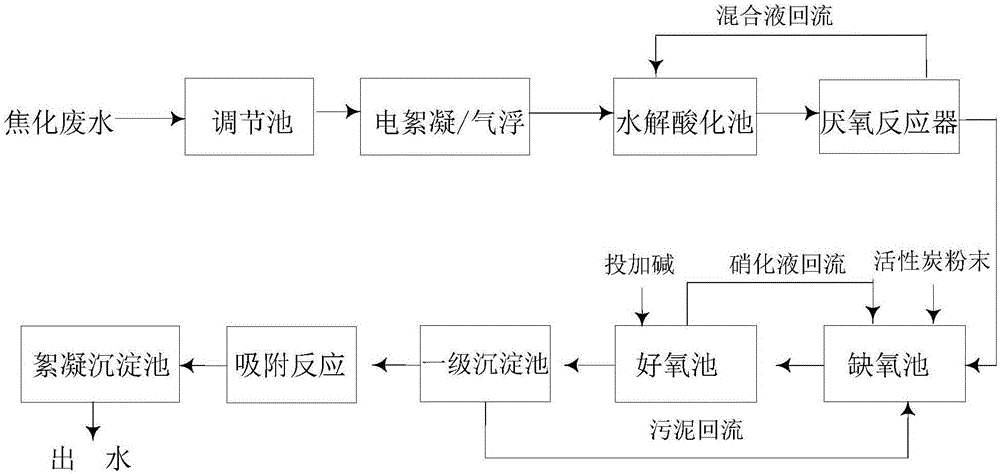

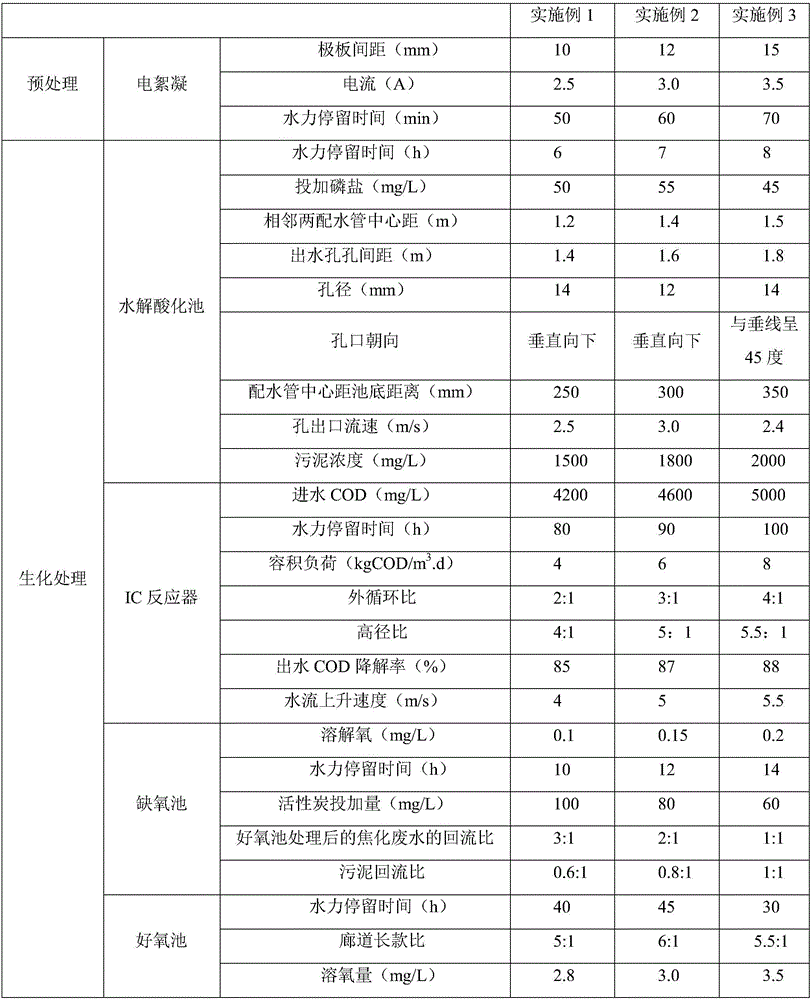

[0034] Embodiments 1 to 3 are all based on figure 1 The coking wastewater is treated in the middle treatment process flow chart. The main indicators of coking wastewater influent are COD 4600mg / L, ammonia nitrogen 110mg / L, pH value 8.9, volatile phenol 800mg / L, petroleum 100mg / L, chroma 600 times, implementation The process parameters of Examples 1-3 are shown in Table 1.

[0035]

[0036]

[0037] The removal effects of coking wastewater in Examples 1-3 are shown in Table 2.

[0038] COD (mg / L) Ammonia nitrogen (mg / L) Volatile phenol (mg / L) Petroleum (mg / L) Chroma Example 1 75 3.2 0.1 2 50 Example 2 70 4.5 0.08 1.8 60 Example 3 67 5.1 0.07 1.9 60

[0039] It can be seen from Table 2 that the coking wastewater treated by the method of Examples 1-3 has COD<80mg / L, ammonia nitrogen<6mg / L, volatile phenol<0.3mg / L, petroleum <2.5mg / L, and the process effluent is stable , meet the GB16171-2012 Table 2 inline standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com